Compound fertilizer anti-caking agent as well as preparation method thereof and compound fertilizer prepared from same

An anti-caking agent and compound fertilizer technology, applied in the direction of nitrogen fertilizer, phosphate fertilizer, organic fertilizer, etc., can solve the problems of soil environmental damage, single function of anti-caking agent, and affecting crop growth, etc., to achieve improved fertilizer efficiency, environmentally friendly and efficient formula, The effect of facilitating product promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

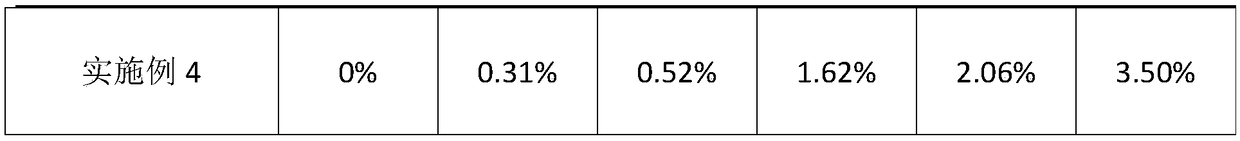

Examples

Embodiment 1

[0027] Embodiment 1: compound fertilizer anti-caking agent 1

[0028] A preparation method of compound fertilizer anti-caking agent, it comprises steps:

[0029] (1) Taking raw materials according to the proportioning ratio for subsequent use;

[0030] (2) Mix the fatty acid and fatty alcohol at a mass ratio of 1:1 and react at 65°C for 2.5 hours to obtain reactant A for use;

[0031] (3) put C 12 -C 18 Alkyl alcohols and phosphorus pentoxide are reacted at 80°C for 6 hours at a ratio of 2.5:1 to obtain phosphoric acid ester for later use;

[0032] (4) 12 parts of reactant A, 8 parts of phosphoric acid ester, 10 parts of span-60, 2 parts of dodecylsulfonate, 15 parts of triethanolamine, 0.6 part of polyglutamic acid, 2- 2 parts of chloro-6-trichloromethylpyridine and 50.4 parts of coconut oil are evenly mixed, then heated and reacted at 70-80° C. to obtain the anti-caking agent for compound fertilizer.

Embodiment 2

[0033] Embodiment 2: compound fertilizer anti-caking agent 2

[0034] A preparation method of compound fertilizer anti-caking agent, it comprises steps:

[0035] (1) Taking raw materials according to the proportioning ratio for subsequent use;

[0036] (2) Mix the fatty acid and the fatty alcohol at a mass ratio of 1:1.2 and react at 80°C for 3 hours to obtain reactant A for later use;

[0037] (3) put C 12 -C 18 Alkyl alcohols and phosphorus pentoxide react at 60°C for 5 hours at a ratio of 2:1 to obtain phosphoric acid ester for later use;

[0038] (4) 18 parts of reactant A, 5 parts of phosphoric acid ester, 5 parts of span-60, 1 part of dodecylsulfonate, 12 parts of triethanolamine, 1 part of polyaspartic acid, 2 parts of polyaspartic acid by mass parts 5 parts of chloro-6-trichloromethylpyridine and 53 parts of soybean oil are uniformly mixed, and then heated and reacted at 80-90 DEG C to obtain the anti-caking agent for compound fertilizer.

Embodiment 3

[0039] Embodiment 3: compound fertilizer anti-caking agent 3

[0040] A preparation method of compound fertilizer anti-caking agent, it comprises steps:

[0041] (1) Taking raw materials according to the proportioning ratio for subsequent use;

[0042] (2) Mix the fatty acid and fatty alcohol at a mass ratio of 1:1 and react at 65°C for 2.5 hours to obtain reactant A for use;

[0043] (3) put C 12 ~C 18 Alkyl alcohols and phosphorus pentoxide are reacted at 80°C for 4 hours at a ratio of 3:1 to obtain phosphoric acid ester for later use;

[0044] (4) 10 parts by mass of reactant A, 10 parts of phosphoric acid ester, 6 parts of span-60, 3 parts of dodecylsulfonate, 15 parts of triethanolamine, 0.4 part of polyglutamic acid, polytian 0.4 parts of aspartic acid, 1 part of 2-chloro-6-trichloromethylpyridine and 54.2 parts of olive oil are evenly mixed, then heated and reacted at 75-80°C to obtain the anti-caking agent for compound fertilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com