Hydraulic continuous drawing mechanism and copper alloy wire rod surface peeling system

A copper alloy, hydraulic technology, applied in metal extrusion, metal wire drawing, metal processing equipment and other directions, can solve the problems affecting the peeling effect of disc products, and achieve the effect of simple structure, power drive, and surface quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

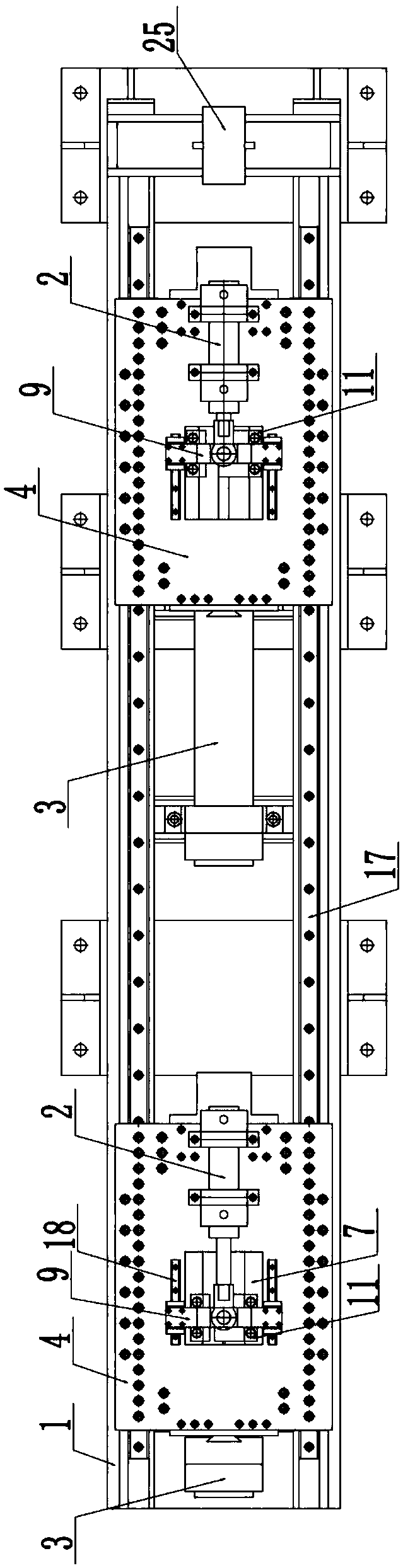

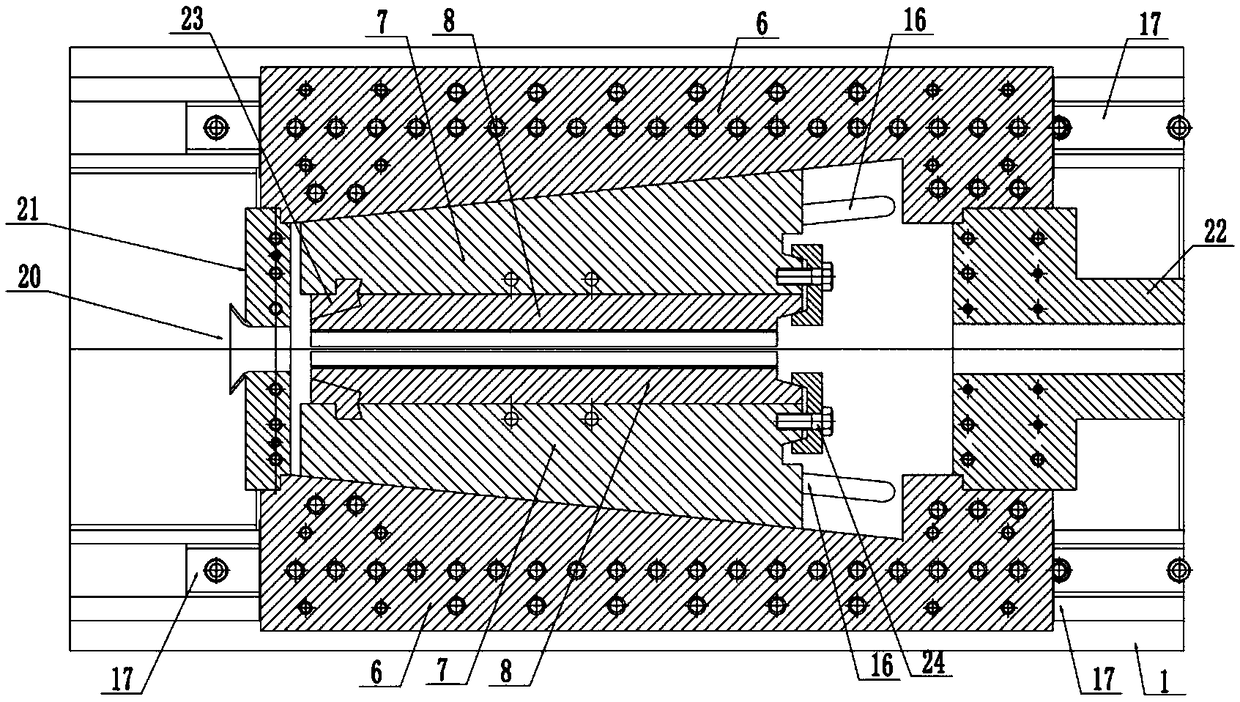

[0047] like Figure 1-Figure 7 As shown, a hydraulic continuous drawing mechanism includes a drawing workbench 1, a front drawing mechanism and a rear drawing mechanism arranged on the drawing workbench 1, and the front and rear drawing mechanisms all include a mobile platform, Large oil cylinder 3 and small oil cylinder 2, the mobile platform moves forward and backward on the drawing workbench under the action of the large oil cylinder, the mobile platform includes a top plate 4, a bottom plate 5, and is located between the top plate and the bottom plate A pair of positioning plates 6, a pair of slide plates 7, and a pair of half-moulds 8, a pair of positioning plates are installed between the top plate and the bottom plate, a pair of positioning pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com