Catalyst for lowering regeneration temperature of diesel particulate filter (DPF) and preparation method of catalyst

A technology for regenerating temperature and catalyst, which is applied in catalyst activation/preparation, chemical instruments and methods, chemical elements of heterogeneous catalysts, etc. Low, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

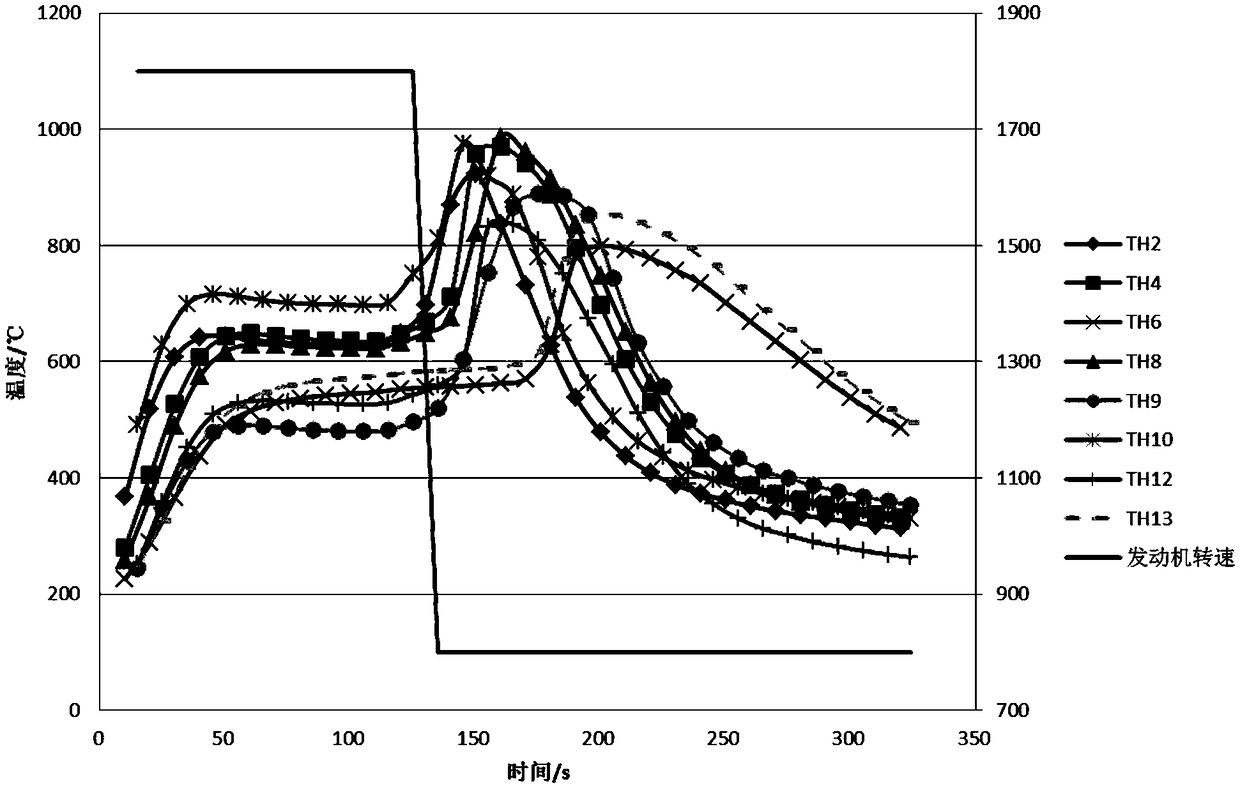

Image

Examples

Embodiment 1

[0030] A catalyst capable of lowering the regeneration temperature of DPF, the catalyst carrier is SiC, the volume is 3.3L, the pore density is 300 mesh / square foot; the coating contains γ-alumina, cerium oxide, magnesia, and γ-alumina and oxide The mass ratio of the mixture of cerium and magnesium oxide is 10:1; the coating amount of the coating is 5g / L; the precious metal is platinum, and the coating amount of the precious metal platinum is 0.1g / L.

[0031] A kind of preparation method of the catalyst that reduces DPF regeneration temperature, comprises the following steps:

[0032] (1) Preparation of coating slurry: Weigh 360g of γ-alumina and 36g of a mixture of cerium oxide and magnesia respectively, add deionized water to prepare an aqueous solution, and then make the mass ratio of γ-alumina and other oxides 10 Mix the two prepared aqueous solutions at a ratio of 1, and fully stir for 3 hours, and then further add additives to adjust the pH value;

[0033] (2) Slurry ba...

Embodiment 2

[0039] A catalyst capable of lowering the regeneration temperature of DPF. The catalyst carrier is SiC, with a volume of 3.3L and a pore density of 300 mesh / square foot; the coating contains γ-alumina, cerium-zirconium composite oxide, titanium oxide, and γ-oxidation The mass ratio of aluminum to cerium-zirconium composite oxide and titanium oxide mixture is 8:1; the coating amount is 20g / L; the precious metals are platinum and palladium, and the mass ratio of platinum and palladium is 1:1. Amount 1.1g / L.

[0040] A kind of preparation method of the catalyst that reduces DPF regeneration temperature, comprises the following steps:

[0041] (1) Preparation of coating slurry: Weigh 360g of γ-alumina and 45g of a mixture of cerium-zirconium composite oxide and titanium oxide respectively, add deionized water to prepare an aqueous solution, and then weigh 360g of γ-alumina and other oxides Mix the two prepared aqueous solutions at a ratio of 8:1, and stir them thoroughly for 3 ho...

Embodiment 3

[0048] A catalyst capable of reducing the regeneration temperature of DPF, the catalyst carrier is AT, the volume is 3.3L, and the pore density is 300 mesh / square foot; the coating contains γ-alumina and manganese oxide, and the mass of γ-alumina and manganese oxide The ratio is 6:1; the coating amount of the coating is 10g / L; the noble metals are platinum and palladium, the mass ratio of platinum and palladium is 15:1, and the coating amount of the noble metal is 0.3g / L;

[0049] A kind of preparation method of the catalyst that reduces DPF regeneration temperature, comprises the following steps:

[0050] (1) Preparation of coating slurry: Weigh 360g of γ-alumina and 60g of manganese oxide respectively, add deionized water to prepare an aqueous solution, and then mix γ-alumina and other oxides at a mass ratio of 6:1 The two prepared aqueous solutions were mixed and fully stirred for 3 hours, and then further additives were added to adjust the pH value;

[0051] (2) Slurry ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com