Reverse water jet ventilation bubble assist high speed water inlet impact reduction load mechanism

A technology of impact load and cavitation, which is applied in the field of high-speed water entry of moving objects, can solve the problem of large navigation volume and achieve an effect that is conducive to stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

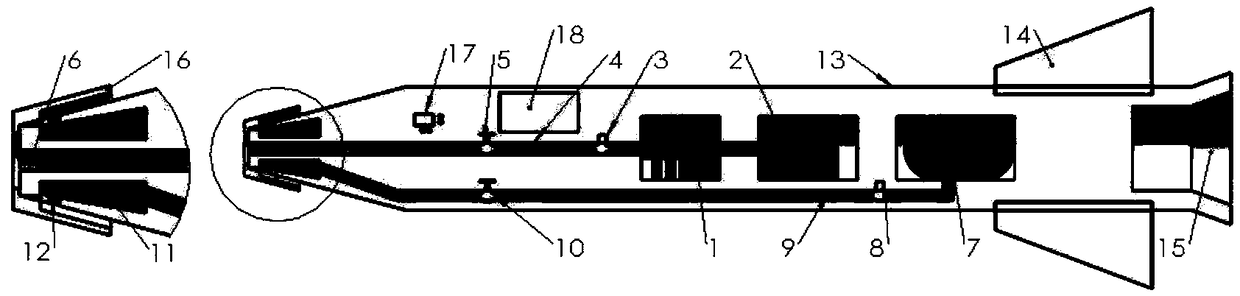

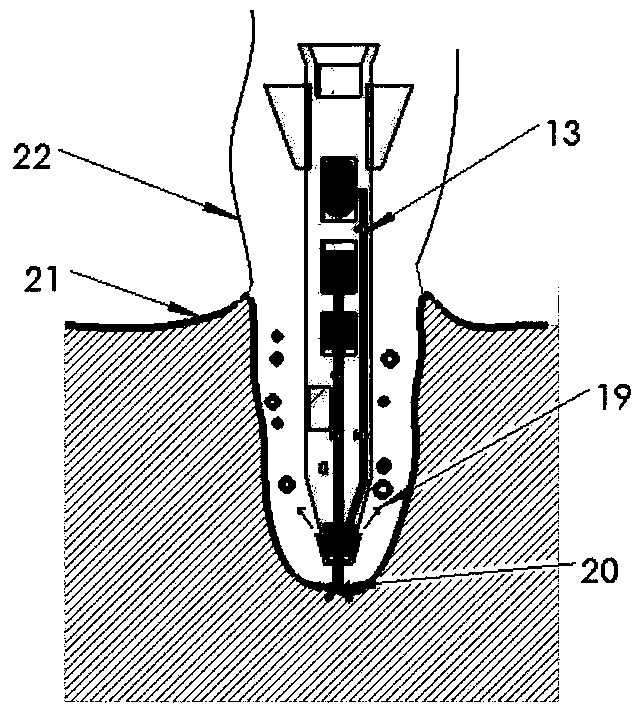

[0011] as attached figure 1 As shown, it is a schematic diagram of the mechanism of the present invention; including a high-pressure water pump 1, a water tank 2, a liquid pressure regulating valve 3, a liquid pipeline 4, a liquid flow meter 5, a high-energy water jet hole 6, a high-pressure gas cylinder 7, and a gas pressure regulating valve 8, gas pipeline 9, gas flow meter 10, air cavity 11, air vent 12, moving body 13, empennage 14, nozzle 15, fairing cover 16, computer control 17, 380 volt battery 18; Connected to the head of the moving body 13, a number of air holes 12 are evenly distributed around the head of the moving body. The air holes 12 communicate with the annular air chamber 11 inside the shell. The high-pressure gas cylinder 7 supplies air to the air chamber through the air circuit. The pressure regulating valve 8 and the gas flow meter 10, the air cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com