Gallium sulfide quantum dot material and preparation method thereof

A quantum dot material, gallium sulfide technology, applied in the field of gallium sulfide quantum dot material and its preparation, can solve the problems of narrow fluorescent emission range, inability to obtain products, non-adjustable, etc., and achieve low cost, simple preparation method, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The concrete steps of preparation are:

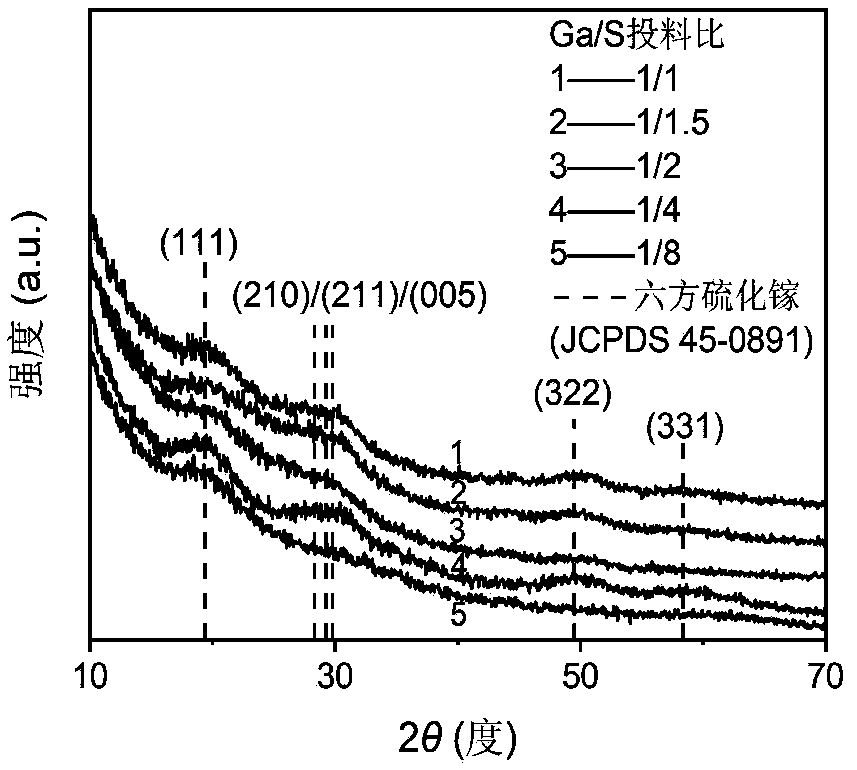

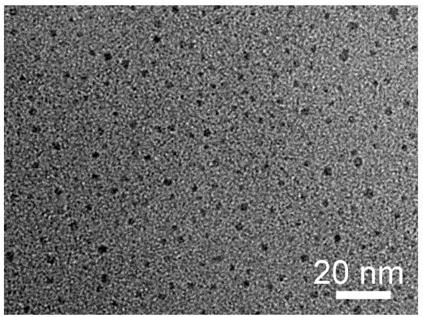

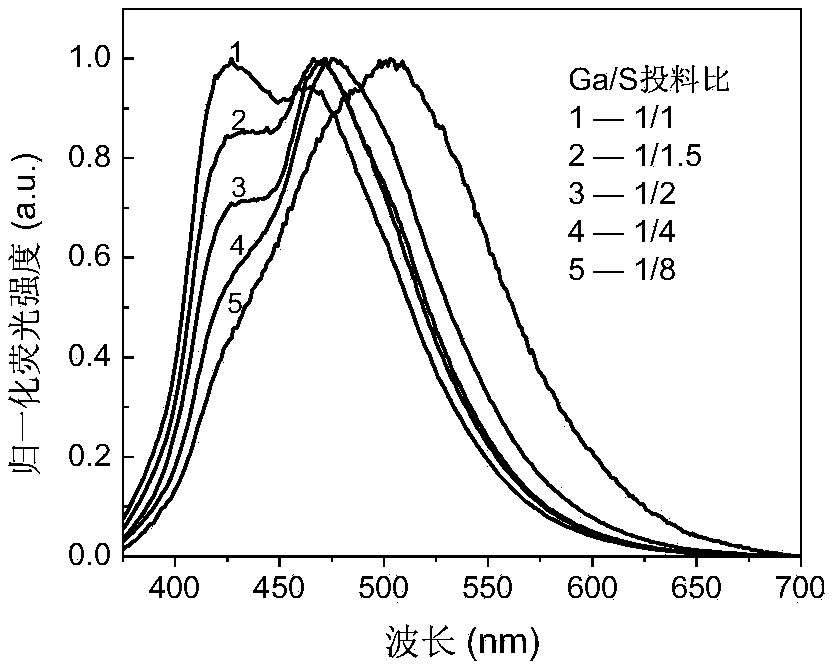

[0041] Step 1, first mix the gallium source, sulfur source, octadecene and ligand at a molar ratio of 1:0.5:80:20; where the gallium source is gallium acetylacetonate, and the sulfur source is sulfur powder , the ligand is a mixture of oleic acid, n-dodecanethiol and oleylamine to obtain a mixed solution. The mixed solution was placed in an inert atmosphere at 100°C for 10 minutes, and then reacted at 220°C for 20 minutes in an inert atmosphere; wherein the inert atmosphere was an argon atmosphere to obtain a reaction solution.

[0042] Step 2, first according to the molar ratio of the gallium source in the reaction solution, the solvent and the precipitant is the ratio of 1:50:1400, add the solvent and the precipitant successively to the reaction solution cooled under the inert atmosphere; wherein, the solvent is n-ethyl Alkanes, the precipitating agent is ethanol, and a suspension is obtained. Then, the suspension is subjecte...

Embodiment 2

[0044] Step 1, first mix the gallium source, sulfur source, octadecene and ligand at a molar ratio of 1:2.5:65:40; where the gallium source is gallium acetylacetonate, and the sulfur source is sulfur powder , the ligand is a mixture of oleic acid, n-dodecanethiol and oleylamine to obtain a mixed solution. The mixture was placed in an inert atmosphere at 105° C. for 8.8 minutes, and then reacted at 240° C. for 15.5 minutes in an inert atmosphere; wherein the inert atmosphere was an argon atmosphere to obtain a reaction solution.

[0045] Step 2, first according to the molar ratio of the gallium source in the reaction solution, the solvent and the precipitant is the ratio of 1:113:1075, add the solvent and the precipitant successively to the reaction solution cooled under the inert atmosphere; wherein, the solvent is n-ethyl Alkanes, the precipitating agent is ethanol, and a suspension is obtained. Then the suspension is subjected to solid-liquid separation treatment; wherein, ...

Embodiment 3

[0047] Step 1, first mix the gallium source, sulfur source, octadecene and ligand at a molar ratio of 1:5:50:60; wherein the gallium source is gallium acetylacetonate, and the sulfur source is sulfur powder , the ligand is a mixture of oleic acid, n-dodecanethiol and oleylamine to obtain a mixed solution. The mixture was placed in an inert atmosphere at 110° C. for 7.5 minutes, and then reacted at 260° C. for 11 minutes in an inert atmosphere; wherein the inert atmosphere was an argon atmosphere to obtain a reaction solution.

[0048]Step 2, first according to the molar ratio of the gallium source in the reaction solution, the solvent and the precipitating agent is the ratio of 1:175:750, add the solvent and the precipitating agent successively in the reaction solution cooled under the inert atmosphere; wherein, the solvent is n-ethyl Alkanes, the precipitating agent is ethanol, and a suspension is obtained. Then, the suspension is subjected to solid-liquid separation treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com