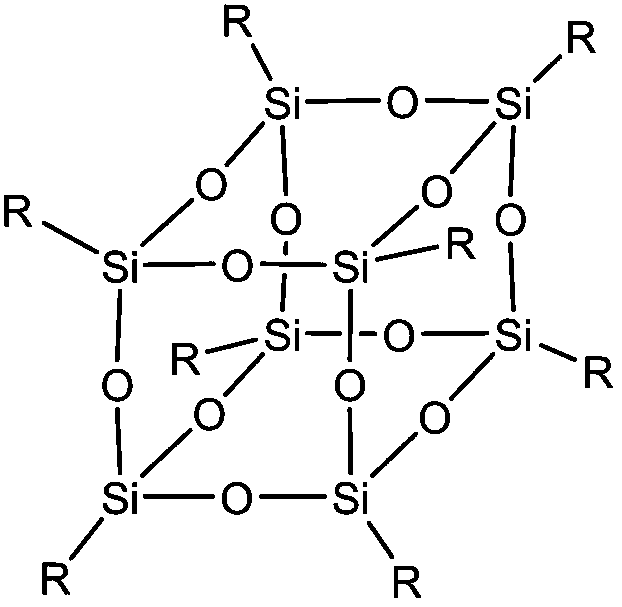

Organosilicon cross-linking agent containing cage oligomeric silsesquioxane structure and preparation method thereof

A technology of polysilsesquioxane and organosilicon crosslinking agent, which is applied in the field of organosilicon crosslinking agent containing cage oligomeric silsesquioxane structure and its preparation, which can solve the problem of poor mechanical properties and adhesive properties and other problems, to achieve the effect of convenient operation, high compatibility and good market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

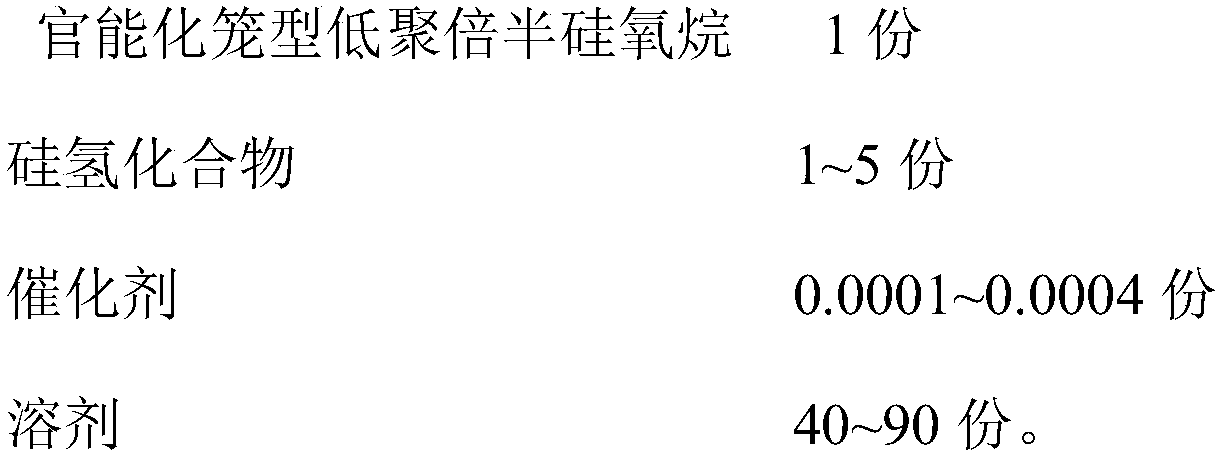

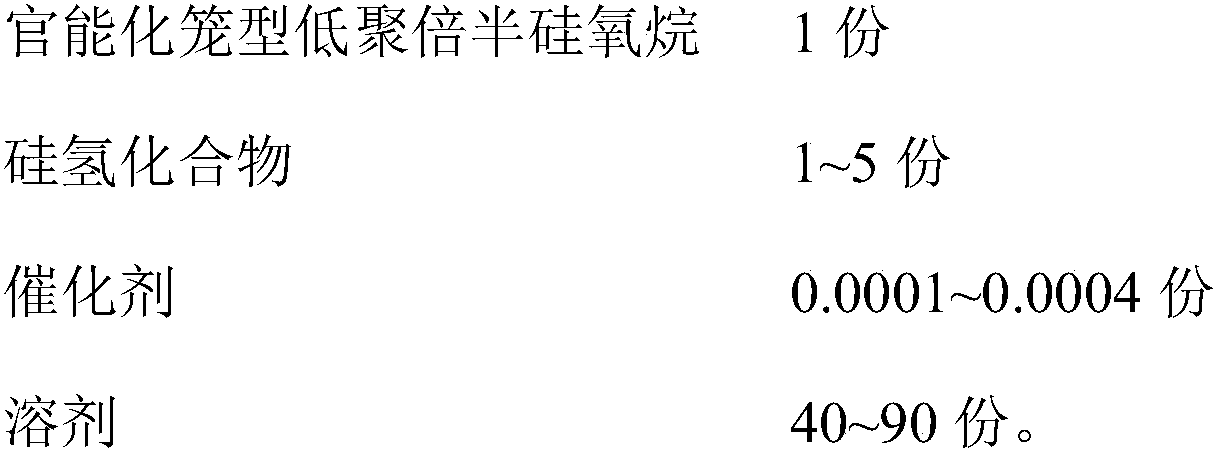

[0039] A method for preparing an organosilicon crosslinking agent containing a cage-type oligomeric silsesquioxane structure. The preparation process steps are as follows, and each component is by weight:

[0040] (1) Preparation of functionalized cage oligomeric silsesquioxane pre-reaction solution:

[0041] Add 20 to 40 parts of the solvent into the reactor, protect it with N2, and slowly add 1 part of functionalized cage-type oligomeric silsesquioxane monomer into the reactor at room temperature, and stir slowly while adding. After the addition is completed, Stir rapidly for 1-2 hours, heat up to 50-60°C, continue to stir until a colorless or light yellow transparent solution; naturally cool to room temperature, add 0.0002-0.0004 parts of catalyst to obtain a functionalized cage oligomeric silsesquioxane pre-reaction solution ;

[0042] (2) Preparation of cage-type oligomeric silsesquioxane-based organosilicon crosslinking agent:

[0043]Mix and dissolve 1 to 5 parts of s...

Embodiment 1

[0047] (1) Preparation of functionalized cage oligomeric silsesquioxane pre-reaction solution

[0048] Add 20g tetrahydrofuran into the four-necked flask, pass N 2 protection, slowly add 1g of octavinyl POSS at room temperature, after the addition is complete, raise the temperature to 60°C, and stir rapidly for 2 hours until the solution is colorless or light yellow and transparent. Naturally cooled to room temperature, 0.0002 g of chloroplatinic acid catalyst was added thereto to obtain a pre-reaction liquid.

[0049] (2) Preparation of cage-type oligomeric silsesquioxane-based crosslinking agent

[0050] 1g of phenylhydrogensilane (0.6% hydrogen content) was mixed and dissolved with 20g of tetrahydrofuran, and slowly added dropwise to the cage-type oligomeric silsesquioxane pre-reaction solution at room temperature. After the reaction was completed, the catalyst was adsorbed and removed by activated carbon, and the solvent was distilled off under reduced pressure to obtain...

Embodiment 2

[0052] (1) Preparation of functionalized cage oligomeric silsesquioxane pre-reaction solution

[0053] Add 20g tetrahydrofuran into the four-necked flask, pass N 2 protection, slowly add 1g of octavinyl POSS at room temperature, after the addition is complete, raise the temperature to 60°C, and stir rapidly for 2 hours until the solution is light yellow and transparent. Naturally cooled to room temperature, 0.0002 g of chloroplatinic acid catalyst was added thereto to obtain a pre-reaction liquid.

[0054] (2) Preparation of cage-type oligomeric silsesquioxane-based crosslinking agent

[0055] Mix and dissolve 1.2g phenyl hydrogen-containing silicone oil (hydrogen content: 0.5%) and 30g toluene, and slowly add it dropwise to the cage-type oligomeric silsesquioxane pre-reaction solution at room temperature. After the reaction was completed, the catalyst was adsorbed and removed by activated carbon, and the solvent was distilled off under reduced pressure to obtain a light yel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com