Acid-free pretreatment process for steel wires

A technology of steel wire and steel wire roller, which is applied in the direction of manufacturing tools, metal processing equipment, grinding feed movement, etc., can solve the problems of low production efficiency, inability to completely remove the oxide layer on the surface of steel wire, and physical rust removal, etc. Removal rate, increase rust removal effect, optimize adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

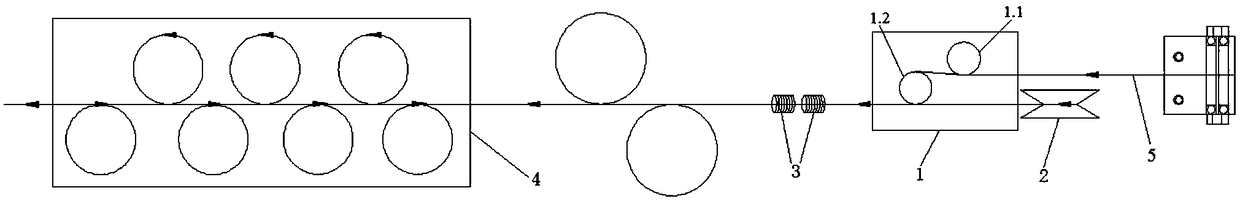

[0042] Such as Figure 1-5 As shown, a batch physical rust removal device for steel wires includes a vertical shelling wheel 1, a horizontal shelling wheel 2, a spiral wire brush 3 and a rust remover 4.

[0043] Described vertical peeling wheel 1 comprises first roller 1.1 and the second roller 1.2 that are vertically arranged, and described first roller 1.1 is positioned at the top of second roller 1.2, but the highest point of the wheel groove of second roller 1.2 is positioned at first. Between the highest point and the lowest point of the wheel groove of the roller 1.1, so that when the steel wire 5 passes through the wheel groove at the lowest point of the wheel groove of the first roller 1.1 and the wheel groove at the highest point of the wheel groove of the second roller 1.2, the upper and lower Deformation, bending and peeling of oxide scale on the lower surface.

[0044] The horizontal peeling wheel 2 is horizontally arranged on the right side of the second roller 1...

Embodiment 2

[0048] A batch physical derusting device for steel wires, the same as in Example 1, the difference is that: the vertical shelling wheel 1 and the horizontal shelling wheel 2 are both made of YG8 hard alloy steel, with a diameter of 125mm and a wheel groove depth 15mm. The spiral rod 3.1 is made of 65# steel, the derusting wire 3.2 is made of 80# steel with a diameter of 0.2 mm and a length of 10 cm, and the diameter of the spiral rod 3.1 is 8 cm. The length of the spiral wire brush is 150mm, and the pitch is 30mm. The roller wire 4.2 is made of steel wire with a diameter of 0.3 mm and a length of 0.2 mm.

experiment example 1

[0050] A batch physical derusting device for steel wires, the same as in Embodiment 2, the difference lies in that the spiral wire brush 3 is not included in the device.

[0051] Test 1: the derusting effects of the devices of embodiment 2 and experimental example 1 were tested using steel wires produced in the same batch and under the same conditions. The results showed that a large amount of oxide scales fell under the spiral wire brush 3, And there is no obvious oxide skin below the steel wire that is not provided with spiral steel wire brush 3, this is mainly that the spiral steel wire brush 3 of the present invention design can compress certain distance along the moving direction of steel wire under the effect of steel wire, makes derusting wire self The holding force between the wire and the steel wire is always automatically adjusted to the state suitable for the rust removal of the steel wire, which maximizes the rust removal effect of the steel wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com