Preparation method of colloidal suspension agent

A technology of colloidal suspensions and wetting agents, which is applied in the field of preparation of colloidal suspensions, can solve problems such as drug resistance, and achieve the effects of low toxicity, low volatility, and safe storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

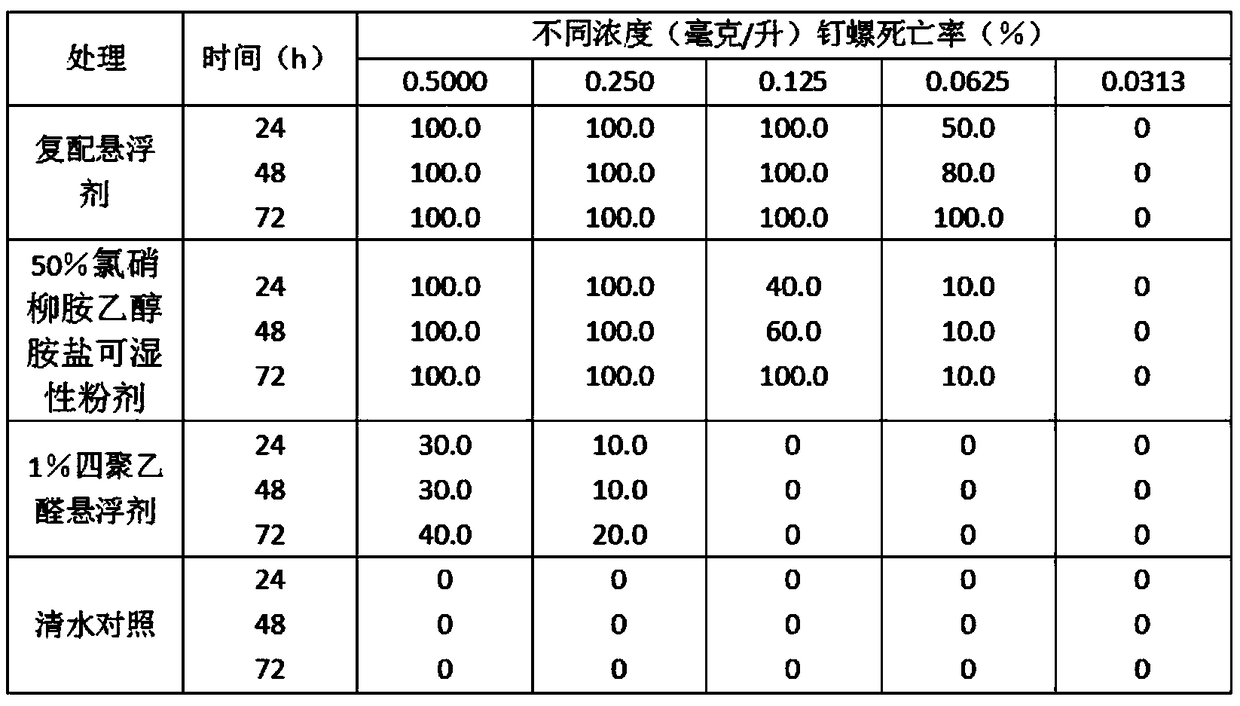

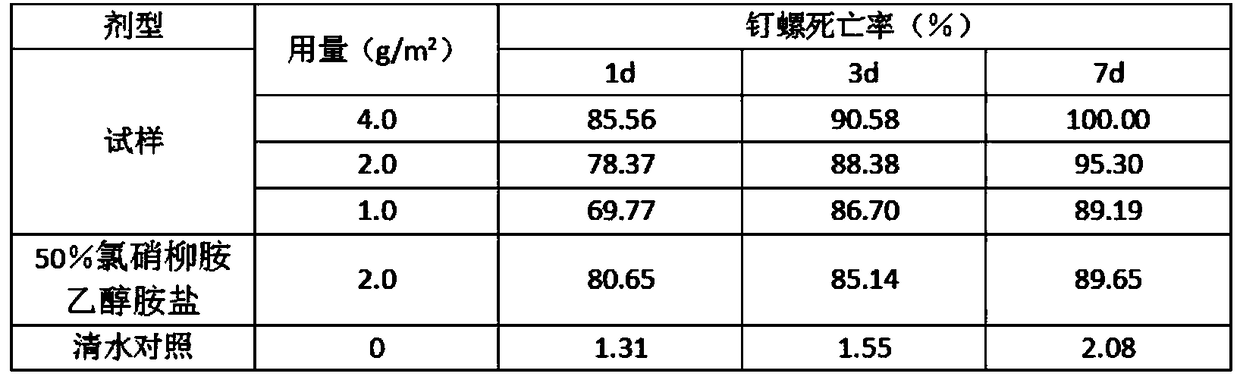

Examples

Embodiment 1

[0015] 30% niclosamide ethanolamine salt + 1% metaldehyde suspending agent in mass percentage, niclosamide ethanolamine salt 30%, metaldehyde 1%, alkylphenol polyoxyethylene ether 2%, polycarboxylate Naphthalene sodium salt 2%, sodium methylene bis-naphthalene sulfonate 3%, ethylene glycol 5%, benzoic acid 1%, organosilicone defoamer 0.5%, Cathone 0.2%, xanthan gum 0.2%, after Grind to 2-3um with a multi-stage sand mill to prepare 30% niclosamide ethanolamine salt + 1% metaldehyde SC.

Embodiment 2

[0017] 45% niclosamide ethanolamine salt + 1% metaldehyde suspending agent in mass percentage, niclosamide ethanolamine salt 45%, metaldehyde 1%, fatty alcohol polyoxyethylene ether 3%, polycarboxylic acid Sodium salt 2%, SOPA (Super) 2703%, Ethylene Glycol 5%, Benzoic Acid 1%, Organic Silicone Defoamer 0.5%, Cathone 0.2%, Xanthan Gum 0.1%, through multi-stage sand mill The grinding is qualified, and 45% niclosamide ethanolamine salt+1% metaldehyde SC is obtained.

Embodiment 3

[0019] 25% niclosamide ethanolamine salt + 1% metaldehyde suspending agent in mass percentage, niclosamide ethanolamine salt 25%, metaldehyde 1%, sodium lauryl sulfate 2%, methylene Sodium bis-naphthalene sulfonate 5%, calcium lignosulfonate 5%, ethylene glycol 5%, benzoic acid 0.3%, organic silicone defoamer 0.5%, Cathone 0.2%, xanthan gum 0.3%, deionized Water topped up to 100%. The components are uniformly mixed with a high-shear emulsifying disperser in this ratio, and ground to 2-3um by a multi-stage sand mill to prepare 25% niclosamide ethanolamine salt + 1% metaldehyde SC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com