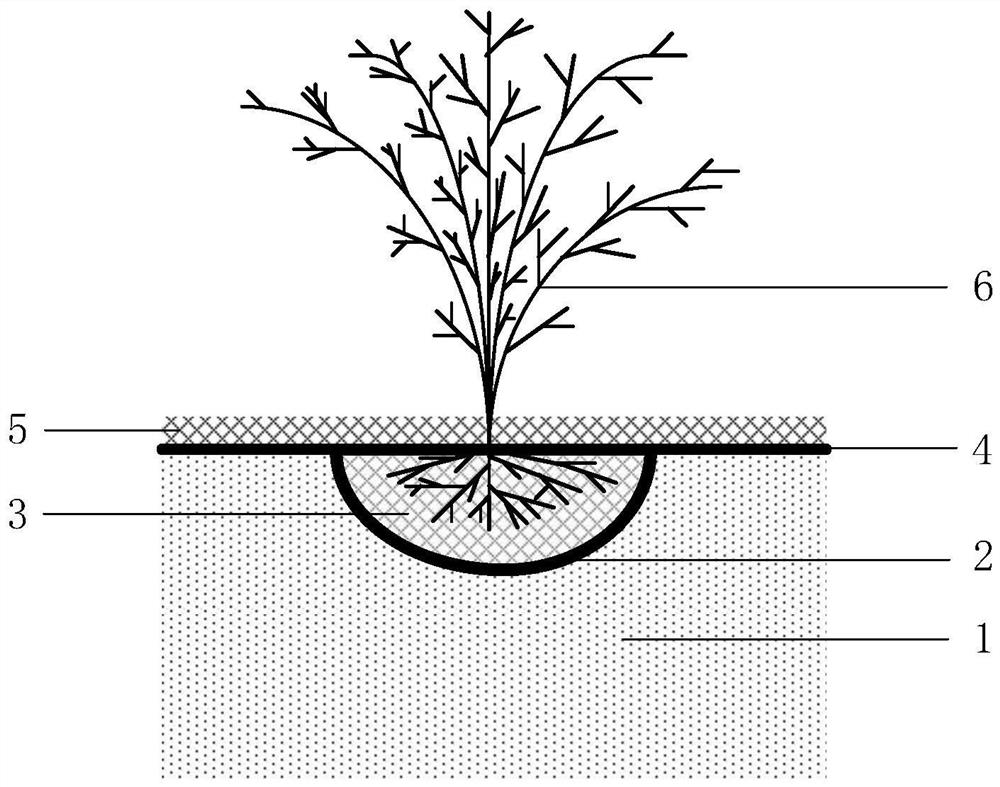

Desert greening planting structure and method for planting plants in desert

A planting structure and desert technology, which is applied in the field of desert control to achieve the effects of being conducive to popularization and application, improving survival rate and avoiding exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Prepare Sand Fixing Agent

[0021] Preparation of plant urease enzyme liquid: weigh dried beans, place them in a pulverizer to crush them, and pass through a 100-mesh sieve for later use (dried at low temperature and sealed for storage to prevent deterioration). Weigh soybean powder and dissolve in water to make soybean powder solution, the concentration of soybean powder is 40g / L. Centrifuge the soy flour solution. The centrifugation process uses a low-temperature high-speed centrifuge. Set the centrifugation temperature to 4°C, the rotation speed to 4000r / s, and the centrifugation time to 15 minutes. After the centrifugation process, discard the bean dregs at the bottom of the centrifuge tube and take the upper clear liquid to obtain plant urease enzyme liquid.

[0022] Preparation of inorganic treatment solution: the concentration of urea is 0.25mol / L, and the concentration of calcium chloride is 0.25mol / L.

[0023] The prepared plant urease enzyme liquid a...

Embodiment 2

[0034] Step 1: Prepare Sand Fixing Agent

[0035]Preparation of plant urease enzyme liquid: weigh dried beans, place them in a pulverizer to crush them, and pass through a 100-mesh sieve for later use (dried at low temperature and sealed for storage to prevent deterioration). Weigh soybean powder and dissolve it in water to make soybean powder solution, the concentration of soybean powder is 20g / L. Centrifuge the soy flour solution. The centrifugation process uses a low-temperature high-speed centrifuge. Set the centrifugation temperature to 2°C, the rotation speed to 3000r / s, and the centrifugation time to 10 minutes. After the centrifugation process, discard the bean dregs at the bottom of the centrifuge tube and take the upper clear liquid to obtain plant urease enzyme liquid.

[0036] Preparation of inorganic treatment solution: the concentration of urea is 0.05 mol / L, and the concentration of calcium nitrate is 0.05 mol / L.

[0037] 30 minutes before use, the prepared pl...

Embodiment 3

[0048] Step 1: Prepare Sand Fixing Agent

[0049] Preparation of plant urease enzyme liquid: weigh dried beans, place them in a pulverizer to crush them, and pass through a 100-mesh sieve for later use (dried at low temperature and sealed for storage to prevent deterioration). Take soybean powder and dissolve it in water to make soybean powder solution, and the concentration of soybean powder is 160g / L. Centrifuge the soy flour solution. The centrifugation process uses a low-temperature high-speed centrifuge. Set the centrifugation temperature to 6°C, the rotation speed to 6000r / s, and the centrifugation time to 30 minutes. clear liquid to obtain plant urease enzyme liquid.

[0050] Preparation of inorganic treatment liquid: the concentration of urea is 0.5 mol / L, and the concentration of calcium chloride is 0.5 mol / L.

[0051] The prepared plant urease enzyme solution and the inorganic treatment solution are uniformly mixed at a volume ratio of 1:5 to obtain a sand-fixing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com