Method for preparing cathode material ZnS/C-SnO2 of sodium ion battery by utilizing tin sludge

A technology for sodium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of expensive SnO2, not properly recycled and reused, and complicated tin oxide production process, and meet performance requirements. , The effect of low equipment cost and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

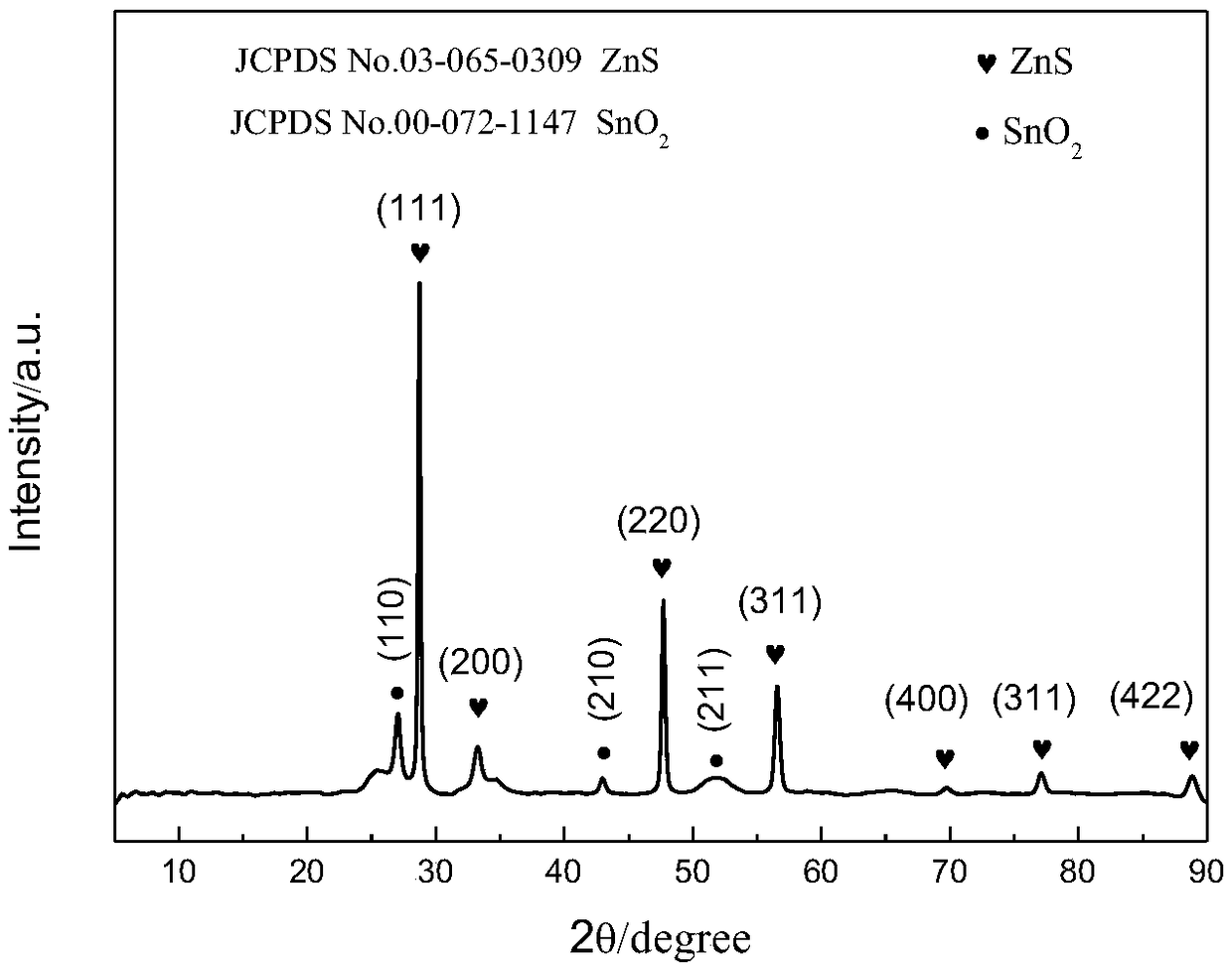

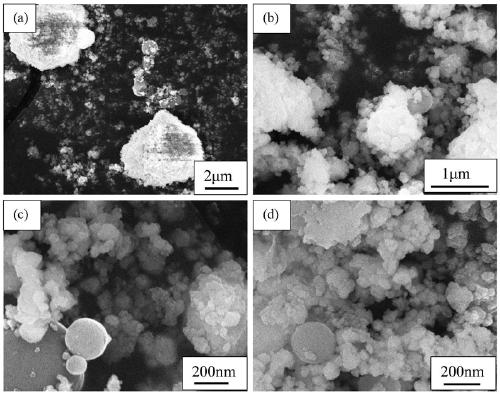

[0052] Example 1: Preparation of ZnS / C-SnO using tin mud 2 composite material

[0053] ①Using zinc acetate, sodium sulfide and anhydrous glucose as raw materials, weigh 2.153g of C 4 h 6 o 4 Zn·2H 2 O, 4.712g of Na 2 S·9H 2 O and 5.454g of anhydrous glucose were simultaneously dissolved in 150mL of distilled water to form a clear and transparent solution, then moved into a reaction kettle for hydrothermal reaction at 180°C for 12 hours, centrifuged-washed-ultrasonic dispersion, and the precipitate was washed three times with distilled water and absolute ethanol, respectively, 60 ℃ drying for 12h to obtain a light gray precursor, and then in N 2 Calcined at 750°C for 2h in the atmosphere to obtain ZnS / C material.

[0054] ②The viscous tin sludge obtained directly from the production workshop, in order to remove the influence of impurity ions, was cleaned with distilled water / absolute ethanol, and then the solution was centrifuged, washed 3 times repeatedly, and placed in...

Embodiment 2

[0059] Example 2: Preparation of ZnS / C-SnO using tin mud 2 composite material

[0060] ①Using zinc acetate, sodium sulfide and anhydrous glucose as raw materials, weigh 2.153g of C 4 h 6 o 4 Zn·2H 2 O, 4.712g of Na 2 S·9H 2 O and 5.454g of anhydrous glucose were simultaneously dissolved in 150mL of distilled water to form a clear and transparent solution, then moved into a reaction kettle for hydrothermal reaction at 180°C for 12 hours, centrifuged-washed-ultrasonic dispersion, and the precipitate was washed three times with distilled water and absolute ethanol, respectively, 60 ℃ drying for 12h to obtain a light gray precursor, and then in N 2 Calcined at 750°C for 2h in the atmosphere to obtain ZnS / C material.

[0061] ②The viscous tin sludge obtained directly from the production workshop, in order to remove the influence of impurity ions, was cleaned with distilled water / absolute ethanol, and then the solution was centrifuged, washed 3 times repeatedly, and placed in...

Embodiment 3

[0064] Embodiment 3: Utilize tin mud to prepare ZnS / C-SnO 2 composite material

[0065] ①Using zinc acetate, sodium sulfide and anhydrous glucose as raw materials, weigh 2.153g of C 4 h 6 o 4 Zn·2H 2 O, 4.712g of Na 2 S·9H 2 O and 5.454g of anhydrous glucose were simultaneously dissolved in 150mL of distilled water to form a clear and transparent solution, then moved into a reaction kettle for hydrothermal reaction at 180°C for 12 hours, centrifuged-washed-ultrasonic dispersion, and the precipitate was washed three times with distilled water and absolute ethanol, respectively, 60 ℃ drying for 12h to obtain a light gray precursor, and then in N 2 Calcined at 750°C for 2h in the atmosphere to obtain ZnS / C material.

[0066] ②The viscous tin sludge obtained directly from the production workshop, in order to remove the influence of impurity ions, was cleaned with distilled water / absolute ethanol, and then the solution was centrifuged, washed 3 times repeatedly, and placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com