Coarse-grained model for mesoscale simulation of petroleum molecules and its construction method and prediction method

A coarse-grained and molecular-structured technology, applied in the field of petroleum processing, which can solve the problem of inability to complete the calculation of molecular motion behavior of large petroleum molecular systems, lack of mesoscale coarse-grained model building methods for petroleum molecules, and inability to manage molecular links to form models, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

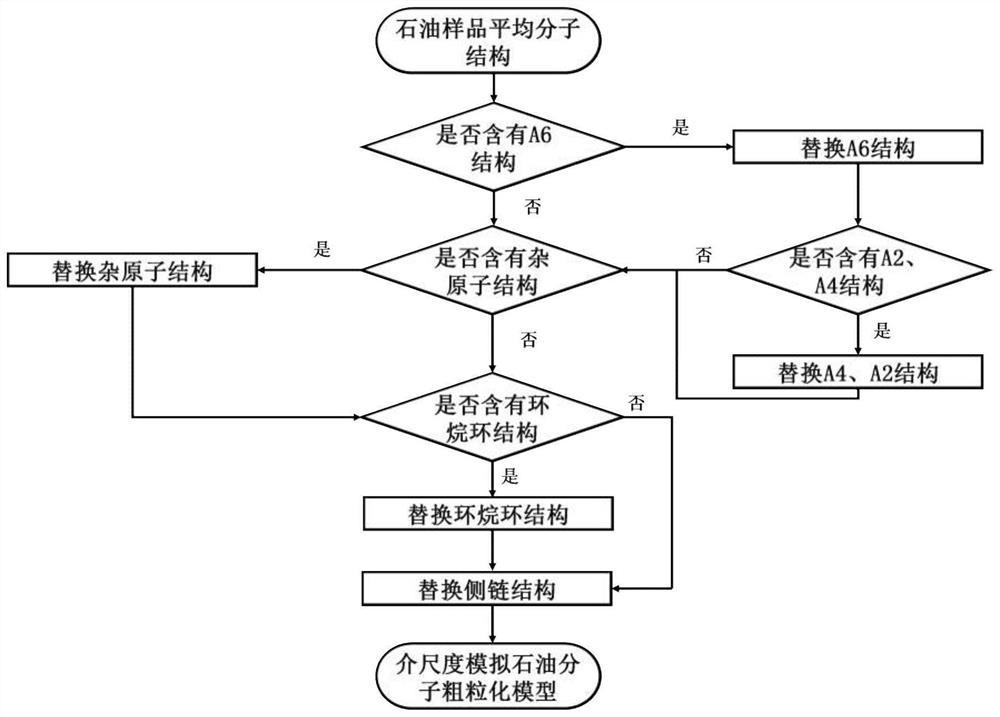

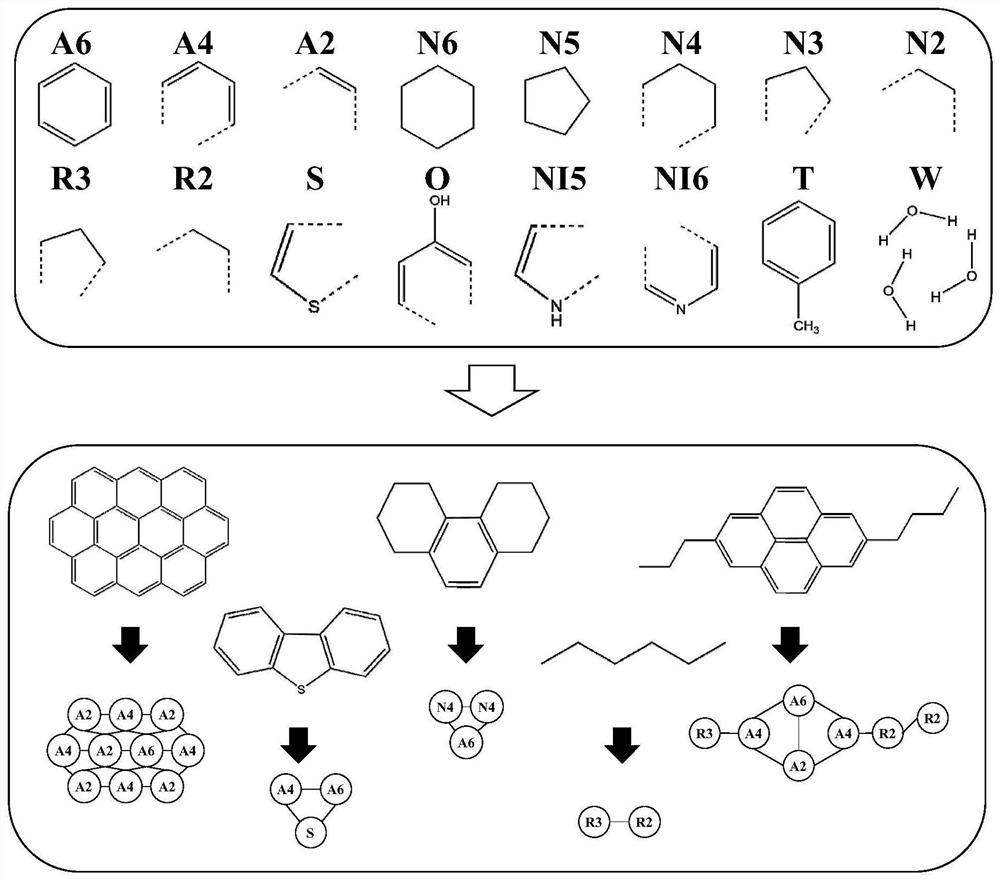

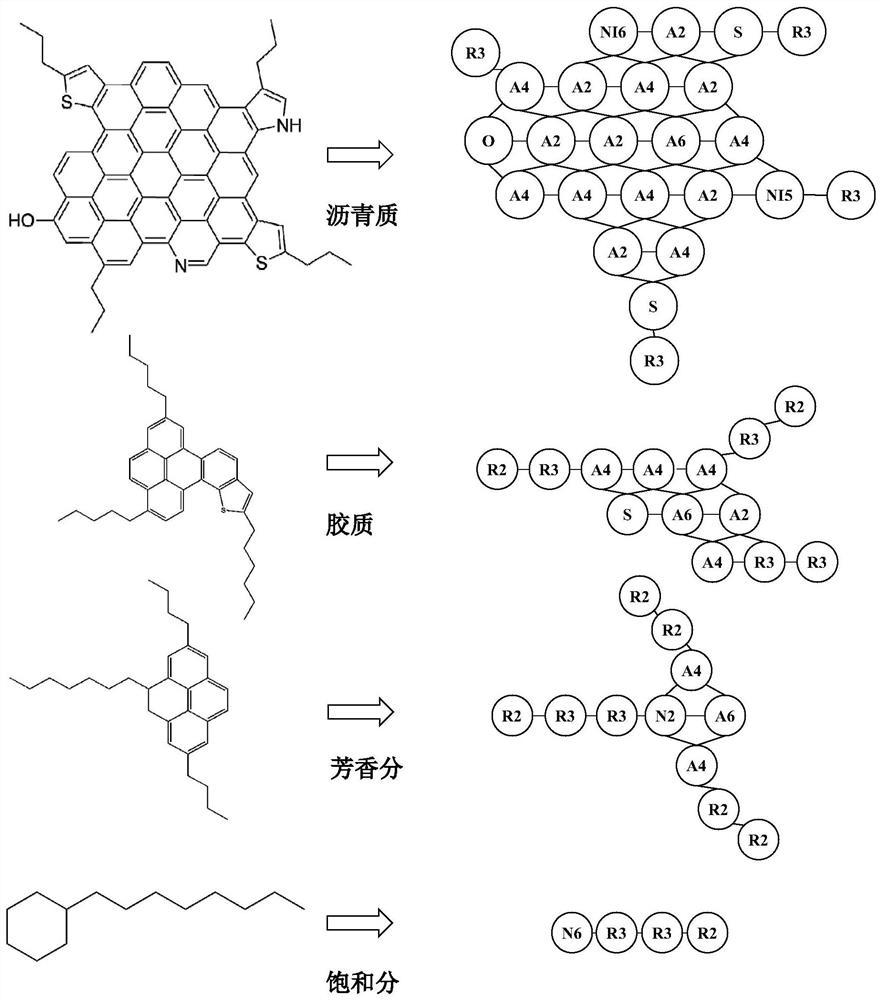

[0051] This embodiment provides a method for constructing a coarse-grained model for simulating petroleum molecules at a mesoscale. figure 1 It is a flowchart of the construction method, and the method includes the following steps:

[0052] Step 1, obtaining the average molecular structure of petroleum samples of different component types; specifically:

[0053] The component types of the petroleum samples in this example include four types: asphaltenes, resins, aromatic components and saturated components. The specific method for obtaining the average molecular structure of the petroleum sample is as follows:

[0054] Determine the element content in petroleum samples; determine the structural parameters of petroleum samples; construct the average molecular structure of different types of petroleum samples.

[0055] Wherein: the elements include carbon, hydrogen, oxygen, nitrogen and sulfur. The structural parameters include aromatic carbon ratio, unit aromatic ring number...

Embodiment 2

[0075] In this embodiment, the toluene solution of asphaltenes is used as a sample, and the obtained coarse-grained model is obtained by the method of Example 1, such as Figure 5 shown. The conservative force parameter table obtained by the method of Example 1 is as shown in above-mentioned Table 1.

[0076] The coarse-grained model and the corresponding conservative force parameters were used for dissipative particle dynamics simulation, and five different concentration simulation systems were established according to 20g / L, 60g / L, 100g / L, 150g / L and 200g / L. Obtain the microscopic equilibrium state structure distribution of the toluene solution of asphaltenes at normal temperature, such as Figure 6 shown. The change curve of asphaltene aggregation rate with concentration is obtained as Figure 7 shown.

[0077] Depend on Figure 5 , Figure 6 and Figure 7 It can be seen that the aggregation number and aggregation rate of asphaltene in toluene increase with the incre...

Embodiment 3

[0079] In this embodiment, the mixed system of the petroleum sample and water in Example 1 is used as the sample, and the coarse-grained model obtained by the method of Example 1 is as follows: Figure 8 shown. The conservative force parameter table obtained by the method of Example 1 is shown in Table 1.

[0080] The coarse-grained model and the corresponding conservative force parameters were used to simulate the dissipative particle dynamics, and six different water-oil ratios were established: 0.5:1, 1:1, 5:1, 10:1, 20:1 and 50:1. Simulation system. Obtain the microscopic equilibrium structure distribution of the mixed system of petroleum sample and water at room temperature, such as Figure 9 shown.

[0081] Depend on Figure 8 and Figure 9 It can be seen that as the water content increases, the system configuration transitions from the water-in-oil configuration to the oil-in-water configuration, and the asphaltene molecules are distributed between the oil-water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com