Gas stove with fire extinguishing apparatus

A technology for a fire extinguishing device and a gas stove, which is applied in the field of kitchen safety, can solve the problems of gas stove explosion, hidden dangers, fires, etc., and achieves the effects of reducing the possibility of fire, reducing the risk of fire, and preventing secondary re-ignition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

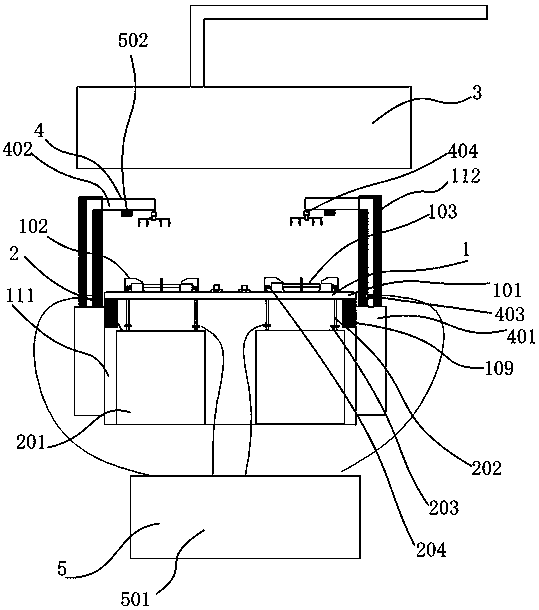

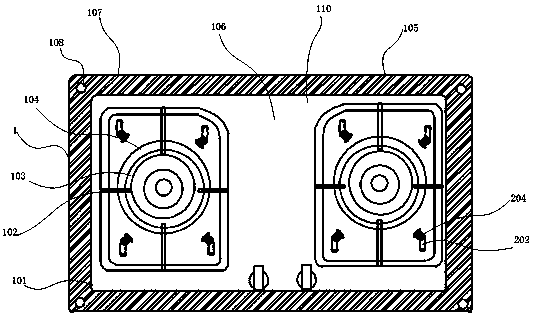

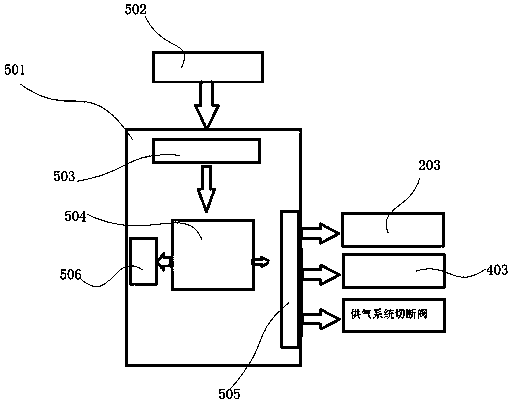

[0021] A gas stove with a fire extinguishing device, comprising a gas stove assembly 1, a stove eye fire extinguishing assembly 2, a smoking assembly 3, a boiler fire extinguishing assembly 4, and a control unit 5, and the inner end of the gas stove assembly 1 is provided with a stove eye fire extinguishing assembly 2. The upper end of the gas cooktop assembly 1 is equipped with a smoking assembly 3, and the smoking assembly 3 is equipped with a boiler fire extinguishing assembly 4, and the stove eye fire extinguishing assembly 2 and the boiler fire extinguishing assembly 4 are respectively electrically connected to the control unit 5 The gas cooktop assembly 1 includes a cooktop panel 101, a pot support 102, a fire ring cover 103 and a cooker body 111, the cooktop panel 101 is arranged on the upper end of the cooker body 111, and the cooktop panel 101 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com