Engine cold start module and start method

A technology for starting a module and an engine, which is applied in the direction of motor starting, engine starting, and engine components, etc., can solve the problems of difficult starting, large starting current, and low service life of vehicles, so as to improve the probability of successful starting and prevent Increase in internal resistance, effect of improving speed and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The engine cold start module of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

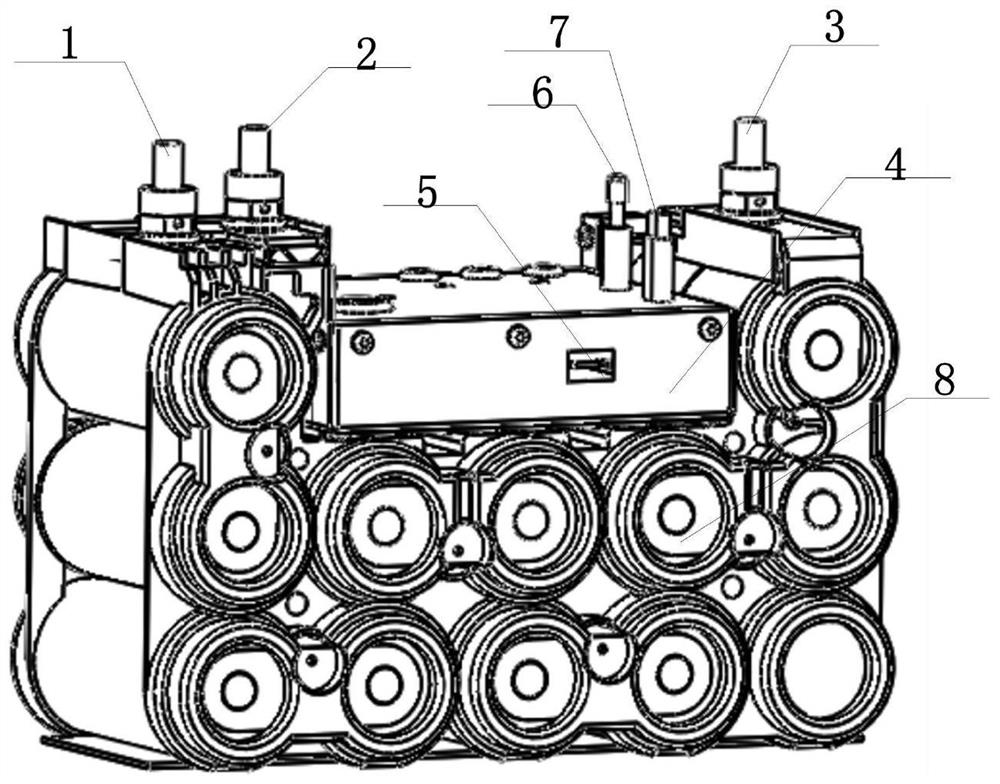

[0040] Such as figure 1 As shown, the engine cold start module includes: a super capacitor core group 8 formed by connecting several super capacitor monomers in series; a DC / DC module 4 installed on the top of the super capacitor core group 8 for charging the super capacitor core group 8 ; Made of high-strength corrosion-resistant and flame-retardant plastics, the supercapacitor core set 8DC / DC module 4 is packaged in one shell. In a preferred solution, the supercapacitor core set 8 is composed of eleven 2.7V3000F supercapacitor monomers connected in series. The super capacitor core group 8 and the DC / DC module are provided with connection terminals, including BATTERY+1 connected to the DC / DC module 4; STARTER+2 connected to the super capacitor core group 8; connected to the super capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com