Grass planting concrete construction based on herbal root system architecture and fabrication method of grass planting concrete construction

A technology of root system configuration and concrete, applied in fertilizer mixtures, applications, inorganic fertilizers, etc., can solve the problems of reduced survival rate and growth vigor of herbs, reduced compressive and flexural strength, inability to adapt to plants, etc. With safety function, improve stress resistance, reduce the effect of growth resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] For herbaceous plants with long fibrous roots, such as vetiver and goosegrass, there is no obvious tap root type, and the root density of the root system is concentrated within 40cm. The distribution of fibrous roots within the thickness of the grass planting concrete is relatively uniform except for the upper layer.

[0039] The total thickness of the grass planting concrete is 12cm, which is divided into 2 layers, the upper layer is 4cm, and the lower layer is 8cm.

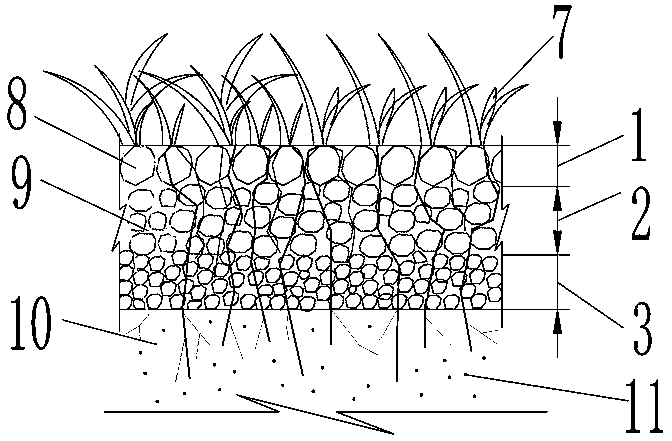

[0040] figure 1 Among them, the upper layer 1 is a grass-planting concrete layer of large-size coarse aggregate, and the lower layer 4 is a grass-planting concrete layer of medium and small-size coarse aggregate. The grass body 7 is planted on the grass-planting concrete 8, and the long root system 10 passes through the pores 9 of the grass-planting concrete. The lower layer of the permeable grass concrete enters the soil layer 11.

[0041] The porosity of the grass-planting concrete in the upper layer 1...

Embodiment 2

[0044] For herbaceous plants with short fibrous roots, such as bermudagrass and tall fescue, the root number density of the root system is concentrated in the range of 2-6cm.

[0045] The total thickness of the grass-planting concrete is 13cm, and it is divided into three layers. The layer thicknesses are 4cm for the upper layer, 6cm for the middle layer, and 3cm for the lower layer.

[0046] figure 2In the middle, the upper layer 1 is a grass-planting concrete layer of large particle size coarse aggregate, the middle layer 2 is a grass planting concrete layer of medium particle size coarse aggregate, and the lower layer 3 is a grass planting concrete layer of small particle size coarse aggregate, and the grass body 7 is planted on the grass planting concrete layer. The concrete 8 and the short herb root system 10 pass through the pores 9 of the grass-planting concrete, and partly penetrate the lower layer of the grass-planting concrete and enter the soil layer 11 .

[0047]...

Embodiment 3

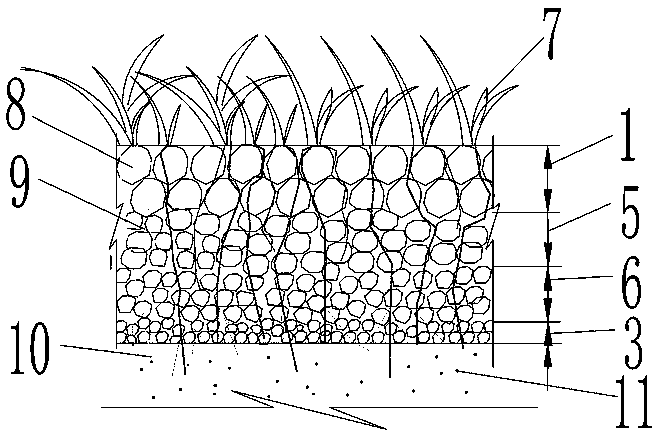

[0050] Targets taprooted herbs such as alfalfa. The root number density of the root system is concentrated in the range of 0-10cm.

[0051] The total thickness of the grass-planting concrete is 15cm, and it is divided into 4 layers. The thickness of each layer is 5cm for the upper layer, 4cm for the upper middle layer, 4cm for the lower layer, and 2cm for the bottom layer.

[0052] image 3 Among them, the upper layer 1 is the grass-planting concrete layer of large particle size coarse aggregate, the middle and upper layer 5 is the grass planting concrete layer of medium particle size coarse aggregate, the middle and upper layer 6 is the grass planting concrete layer of medium particle size coarse aggregate, and the lower layer 3 is the grass planting concrete layer of medium particle size coarse aggregate. The grass-planting concrete layer of coarse aggregate is planted by the grass body 7 on the grass-planting concrete 8, and the short root system 10 of the herb passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com