Rounding grinderabrasive block for rail traffic

A technology for rail transit and grinders, applied in mechanical equipment, brake types, brake components, etc., can solve the problems of affecting the braking effect, the safety performance cannot be guaranteed, and the quality of the grinders cannot be guaranteed, so as to avoid the reduction of bonding strength, The effect of improving driving safety and stability and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

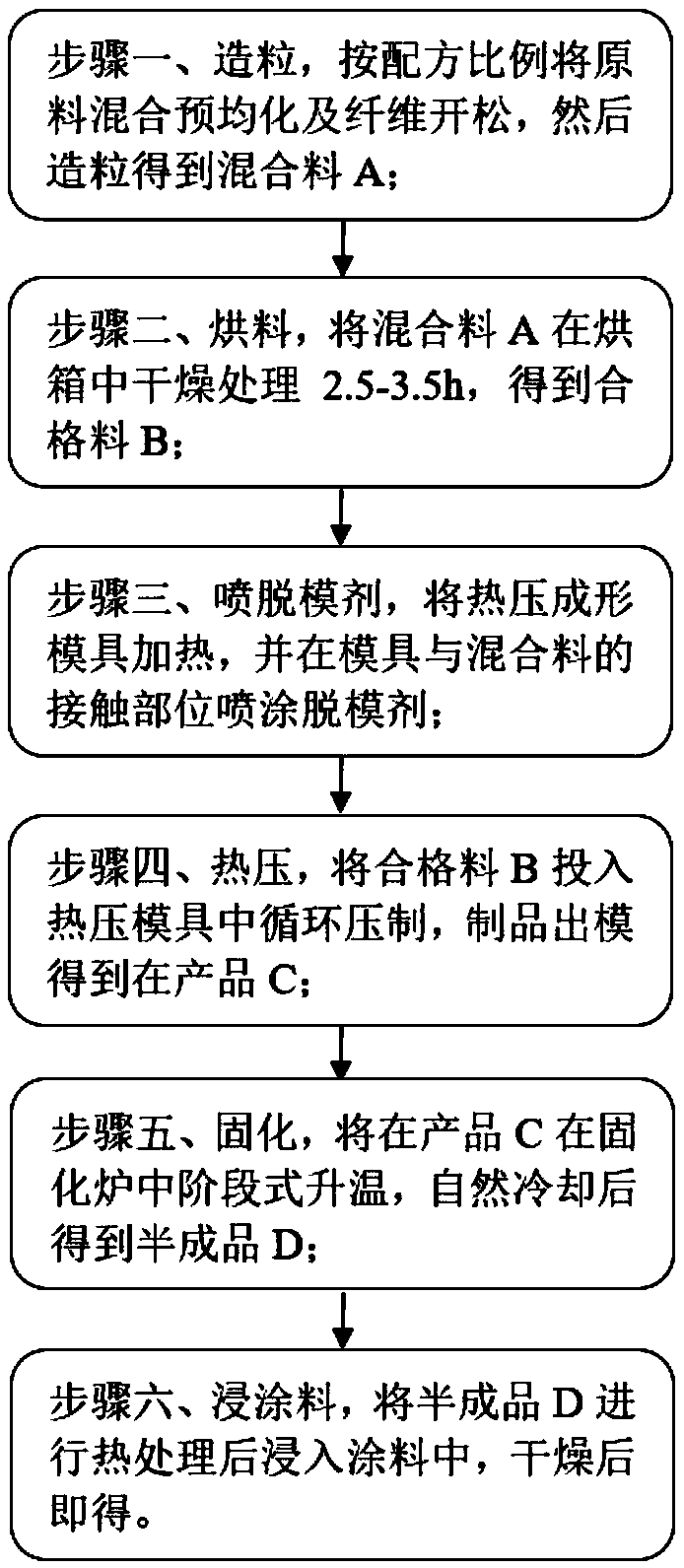

Method used

Image

Examples

Embodiment 1

[0041] to combine figure 1 , a kind of rounding grinder for rail traffic of the present embodiment, comprises the raw material of following weight portion:

[0042] 10 parts of compound binder;

[0043] The composite binder includes an inorganic binder and an organic binder, and the addition ratio of the inorganic binder to the composite binder is 1 / 5, wherein the composite binder includes the following raw materials by weight: 2 parts by weight of the inorganic binder and The organic binding agent of 8 weight parts;

[0044]

[0045]The organic binder described in this embodiment is silicone modified phenolic resin; the inorganic binder is boron glass powder; the rounded particles are zirconium corundum and tabular corundum; the wear reducing aid is phosphor flake graphite ; The fiber is steel fiber and copper-plated fiber, adding an appropriate amount of fiber increases the impact strength of the abrasive; the antioxidant is silicon powder.

[0046] In this embodiment,...

Embodiment 2

[0064] A kind of rounding grinder for rail transit of the present embodiment, its composition is basically the same as embodiment 1, and its difference is: combine figure 1 , a kind of rounding grinder for rail traffic of the present embodiment, comprises the raw material of following weight portion:

[0065] 8 parts of compound binder;

[0066] The composite binder includes an inorganic binder and an organic binder, and the addition ratio of the inorganic binder to the composite binder is 1 / 5, wherein the composite binder includes the following raw materials by weight: 1.6 parts by weight of the inorganic binder and The organic binder of 6.4 parts by weight;

[0067]

[0068] The organic binder described in this embodiment is boron modified aldehyde resin; the inorganic binder is borax; the rounding particles are fused silica and boron nitride; the wear-reducing aid is carbon black; the fiber It is carbon fiber and aramid fiber; the antioxidant is boron carbide.

[0069...

Embodiment 3

[0079] A kind of rounding grinder for rail transit of the present embodiment, its composition is basically the same as embodiment 1, and its difference is: combine figure 1 , a kind of rounding grinder for rail traffic of the present embodiment, comprises the raw material of following weight portion:

[0080] 7.5 parts of composite binder;

[0081] The composite binder includes an inorganic binder and an organic binder, and the addition ratio of the inorganic binder to the composite binder is 3 / 10, wherein the composite binder includes the following raw materials by weight: 2.25 parts by weight of the inorganic binder and The organic binder of 5.25 parts by weight;

[0082]

[0083] The organic binder described in this embodiment is silicone modified phenolic resin and boron modified aldehyde resin; the inorganic binder is boron glass powder and borax; the rounding particles are zirconium corundum, tabular corundum, fused silica and boron nitride; the anti-friction additi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com