Three-dimensional ordered porous ruthenium dioxide membrane electrode and preparation method thereof

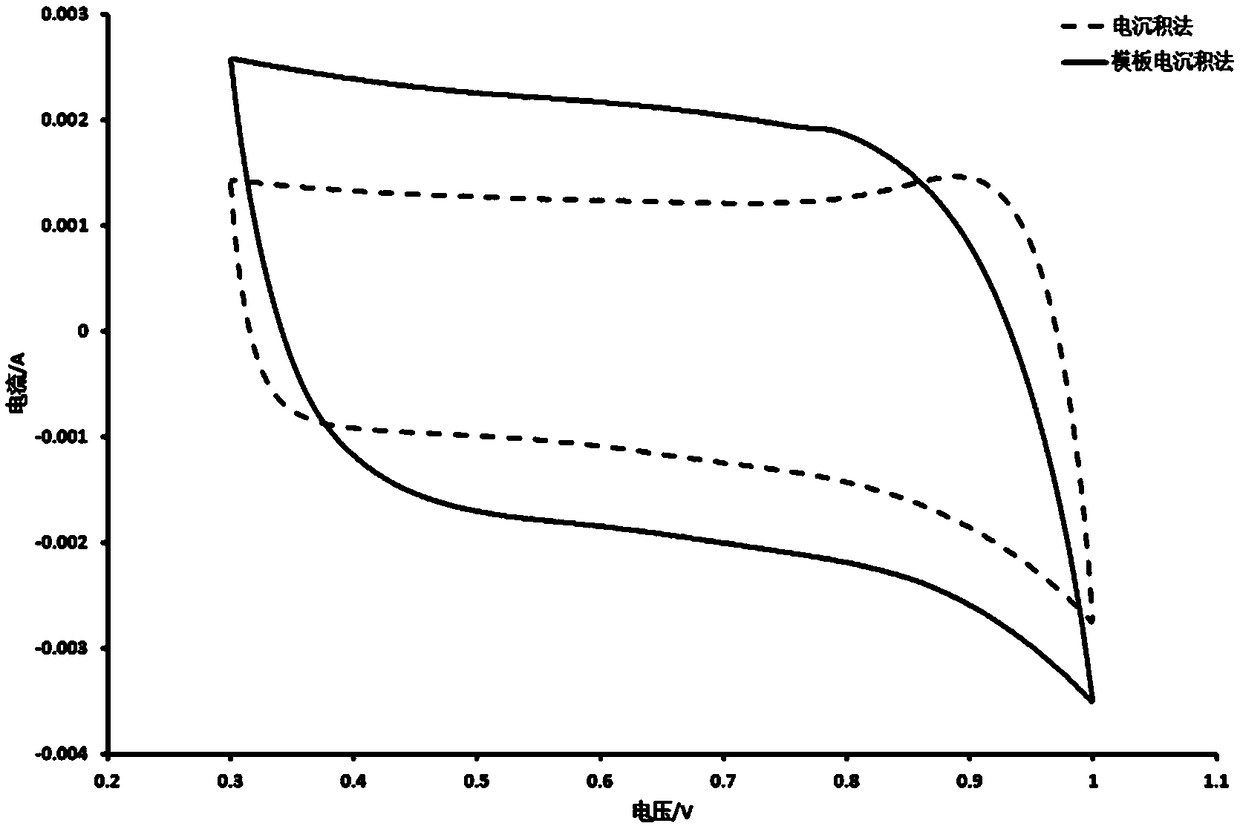

A ruthenium dioxide film, three-dimensional ordered technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. The increase of chemical active area and the low utilization rate of ruthenium dioxide can achieve the effect of increasing electrochemical active sites, increasing specific surface area, and enhancing utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

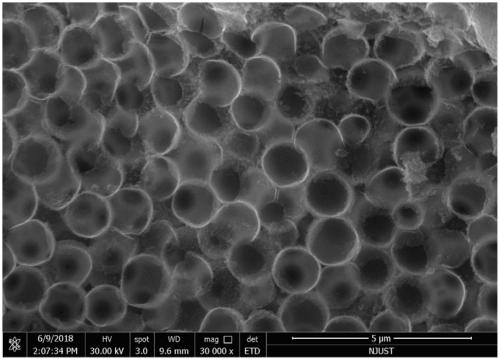

[0030] Example 1 is to prepare a ruthenium dioxide film electrode by electrodeposition on the surface of a porous titanium substrate covered with polystyrene microspheres. The present invention refers to this method as a template electrodeposition method. The present invention prepares the concrete method of ruthenium dioxide film electrode by template electrodeposition as follows:

[0031] Step 1: Cut the titanium plate into a size of 1.0cm×3.0cm, polish the titanium substrate with sandpaper until the surface is flat and smooth; ultrasonically clean the surface to remove oil stains; then heat in 0.2mol / L oxalic acid solution for 1 hour to remove the oxide layer on the surface of the substrate; take out the titanium After the plate, deionized water was added for ultrasonication to remove excess oxalic acid attached to the titanium plate.

[0032] Step 2: Dry the treated titanium plate, drop ultrasonically dispersed 2 μm polystyrene microsphere emulsion on the surface of the ti...

Embodiment 2

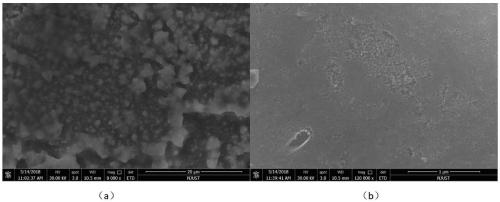

[0037] Embodiment is the method for preparing ruthenium dioxide film electrode by the method for electrodeposition on common titanium plate, we are called this method electrodeposition method, the concrete method of preparing ruthenium dioxide film electrode by electrodeposition method is as follows:

[0038] Step 1: Cut the titanium plate into a size of 1.0cm×3.0cm, polish the titanium substrate with sandpaper until the surface is flat and smooth; ultrasonically clean the surface to remove oil stains; then heat in 0.2mol / L oxalic acid solution for 1 hour to remove the oxide layer on the surface of the substrate; take out the titanium Add deionized water after the plate for ultrasonication to remove excess oxalic acid attached to the titanium plate.

[0039] Step 2: Dry the treated titanium plate.

[0040] Step 3: Preparation of ruthenium dioxide film electrode by electrodeposition. A titanium plate is used as the cathode, and a titanium plate of the same size is used as the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com