Preparation technology and application of porous defect carbon material derived from petroleum coke

A technology of porous carbon materials and petroleum coke, which is applied in the direction of carbon preparation/purification, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of environmental secondary pollution, strong alkali and high chemical corrosion, and achieve optimization Utilization, simple operation, and the effect of increasing the added economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

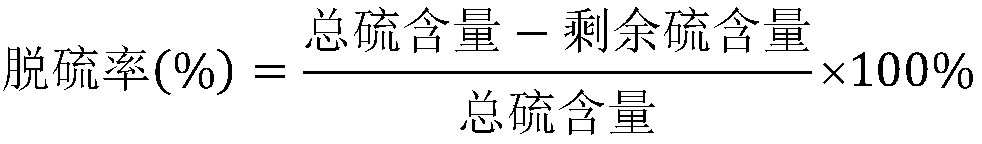

Method used

Image

Examples

Embodiment 1

[0028] (1) The petroleum coke raw material is placed in a pulverizer for preliminary grinding and sieving treatment to obtain pretreated petroleum coke powder with a size of 1-20 μm.

[0029] (2) Weigh urea and petroleum coke powder (molar ratio 5:1) and mix them in a stainless steel ball mill tank, add zirconia balls (3mm in diameter, 40g), assemble them in a planetary ball mill, set the speed at 400rpm, and run the ball mill every 5 minute interval, the interval time is 2.5 minutes, and the total running time is 12 hours.

[0030] (3) Put the ball-milled material into a quartz boat and place it in a tube furnace with nitrogen as a protective gas. The initial temperature is room temperature, and the temperature is raised to 1000°C at 5°C / min, and kept at this temperature for 2 hours, and then After natural cooling down to room temperature, the obtained black solid is the porous carbon material derived from petroleum coke.

[0031] (4) Put the carbon material derived from oil...

Embodiment 2

[0037] (1) The petroleum coke raw material is placed in a pulverizer for preliminary grinding and sieving treatment to obtain pretreated petroleum coke powder with a size of ~1-20 μm.

[0038] (2) Weigh melamine and petroleum coke powder (molar ratio 3:1) and mix them in a stainless steel ball mill tank, add zirconia balls (3mm in diameter, 30g), assemble them in a planetary ball mill, set the speed at 500rpm, and run the ball mill every 5 minute interval, the interval time is 2.5 minutes, and the total running time is 24 hours.

[0039] (3) The material after ball milling was put into a porcelain ark, placed in a tube furnace with argon as a protective gas, the initial temperature was room temperature, the temperature was raised to 900 °C at 10 °C / min, and kept at this temperature for 2 hours, Then naturally cool down to room temperature to obtain a porous carbon material.

[0040](4) Put the porous carbon material into a porcelain ark and place it in a muffle furnace. The i...

Embodiment 3

[0042] (1) The petroleum coke raw material is placed in a pulverizer for preliminary grinding and sieving treatment to obtain pretreated petroleum coke powder with a size of ~1-20 μm.

[0043] (2) Weigh urea and petroleum coke powder (molar ratio 15:1) and mix them in a stainless steel ball mill tank, add zirconia balls (3mm in diameter, 30g), assemble them in a planetary ball mill, set the speed at 400rpm, and run the ball mill every 10 minute interval, the interval time is 5 minutes, and the total running time is 12 hours.

[0044] (3) The material after ball milling was put into a porcelain ark, placed in a tube furnace with nitrogen as a protective gas, the initial temperature was room temperature, the temperature was raised to 800 °C at 5 °C / min, and kept at this temperature for 4 hours, and then Naturally cooling down to room temperature, the porous carbon material is obtained.

[0045] (4) Put the porous carbon material into a porcelain ark and place it in a muffle fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com