Mixed model judgement based crystallizer breakout predication method

A hybrid model and crystallizer technology, which is used in instruments, electrical digital data processing, safety devices, etc., can solve the problems of model false positives and false negatives, insufficient training samples, high reporting rates, etc. The effect of avoiding production accidents and low false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

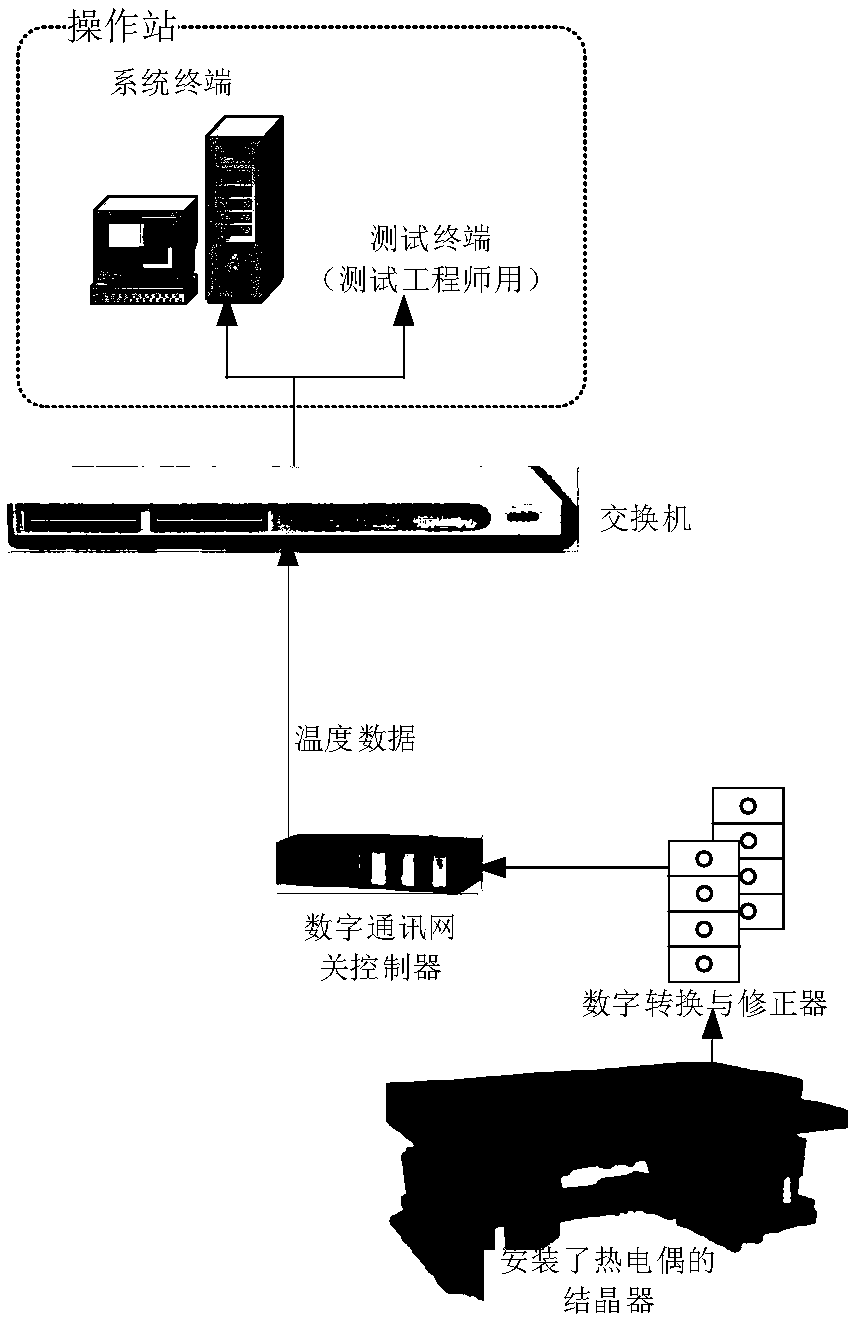

[0043] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0044] The technical scheme that the present invention solves the problems of the technologies described above is:

[0045] The present invention will be described in further detail below in combination with specific embodiments and with reference to the accompanying drawings.

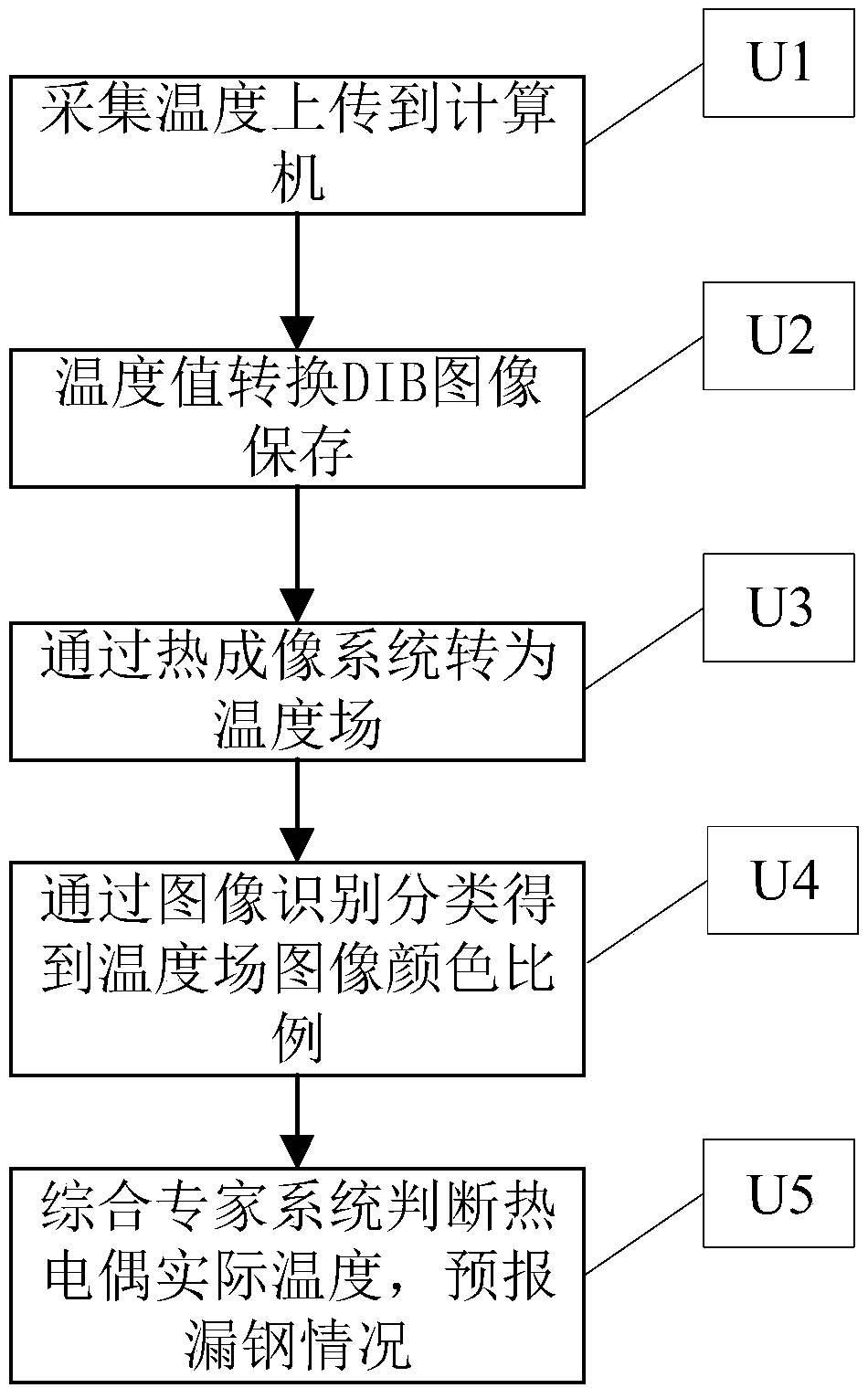

[0046] Such as figure 1 Shown, be the concrete implementation flowchart of the present invention, comprise the following steps:

[0047] U1, collect crystallizer temperature through thermocouple, and upload to computer;

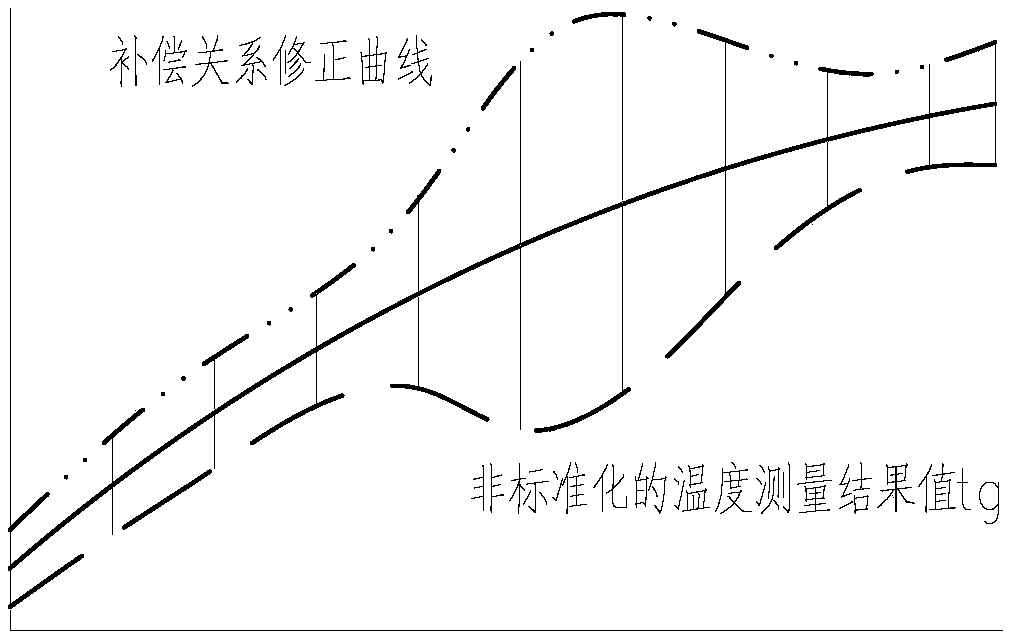

[0048] U2. Correct and model the collected temperature values to obtain a hybrid model. The hybrid model includes an image classification recognition model and an expert system model. The image classification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com