Ultra-deep desulfurization catalyst, preparation method thereof and application of catalyst

A desulfurization catalyst and deep desulfurization technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as cost constraints and complex processes, and achieve the effect of increasing the degree of modification and increasing the relative content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

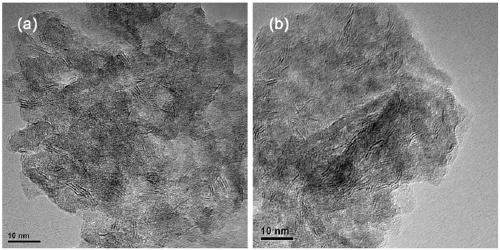

Image

Examples

Embodiment 1

[0042] This implementation provides a kind of preparation method of desulfurization catalyst, and this method comprises the following steps:

[0043] Step 1, take by weighing 1.34g ammonium heptamolybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and 4.50 g of nickel acetate tetrahydrate (Ni(OOCCH 3 ) 2 4H 2 0), it was added to 8mL glacial acetic acid and 100mL water mixed solution and stirred to dissolve, then 0.25g of hydrazine sulfate was added and stirred to dissolve, after about 15min, after hydrazine sulfate was completely dissolved, it was stirred and reacted at a constant temperature in a water bath at 65°C for 3d, The obtained crystalline product was suction-filtered, washed with water and dried to obtain polyoxometalate.

[0044] Step 2: Disperse 0.23g of polyoxometalates in 70mL of deionized water for 5 hours of ultrasonic treatment, then add 1g of aluminum oxide (20-40 mesh), stir evenly, and transfer to polytetrafluoroethylene In the lined autoclave, under...

Embodiment 2

[0055] The present implementation provides a kind of preparation method of the desulfurization catalyst of sulfuration, and it comprises the steps:

[0056] The NiMo-HPD prepared in Example 1 is diluted with quartz sand at a volume ratio of 1:1, and packed into a stainless steel reactor with an internal diameter of 8.0mm and a length of 320mm; 2 Under the conditions, dry at 120°C for 2h, and then introduce a vulcanizing agent (3wt% of CS 2 n-heptane solution), the vulcanization pressure is 4MPa, and the vulcanization agent volume space velocity is 8h -1 , the volume ratio of hydrogen to oil is 300:1, and the temperature is raised to 360°C at a rate of 2°C / min, and kept for 5h to obtain sulfided NiMo-HPD, which is designated as NiMoS-HPD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com