Device and method for laser preparation of boron-doped graphene

A boron-doped and graphene technology is applied in the field of laser preparation of boron-doped graphene devices, which can solve problems such as low conversion efficiency, unfavorable production, and harsh preparation conditions, and achieve the effects of high stability and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The working conditions of the method and device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings, but they are not used to limit the present invention.

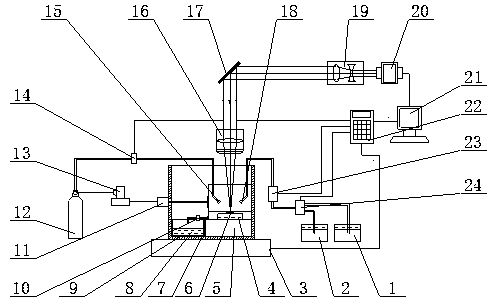

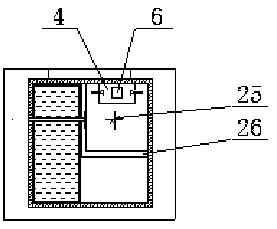

[0019] The device used in this embodiment to prepare boron-doped graphene, such as figure 1 and figure 2 As shown, it includes reaction vessel, laser generating system, computer control system, cleaning system and positioning tightening device. The reaction vessel 7 is divided into a reaction chamber 26 and a collection chamber 9. The reaction chamber 26 contains a mixed solution mixed with deionized water, carbon powder and boric acid in a certain proportion, and a boss 4 on which a copper foil 6 is placed. The rotor 25 of the magnetic stirrer is placed in the mixed solution, and the rotor is made of polyvinyl fluoride and magnetic steel, which is resistant to high temperature, abrasion, corrosion and strong magnetism. The reaction chamber 26 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com