Method for positioning independent cargo space and carrier body of asphalt carrier

A positioning method and asphalt ship technology, which are applied to ship accessories, ships, load handling devices, etc., can solve the problems of large tonnage and volume of independent cargo holds, difficult positioning and installation, high labor and mechanical costs, etc. The effect of improving hoisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

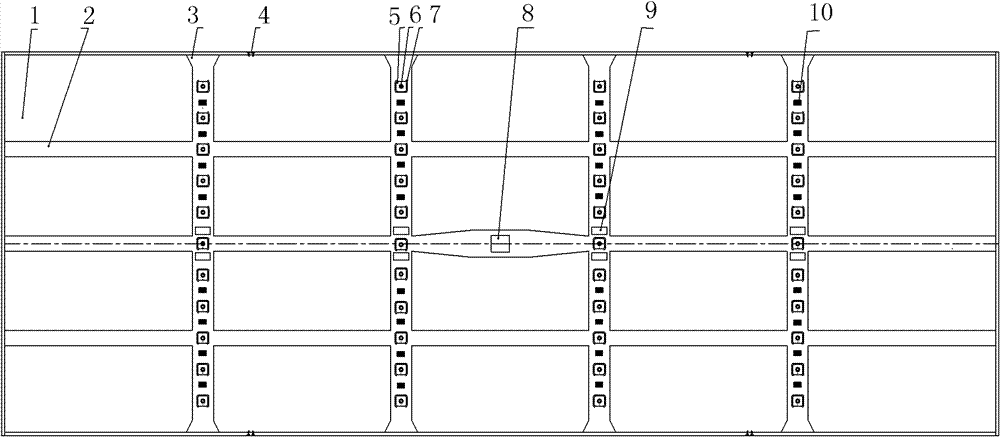

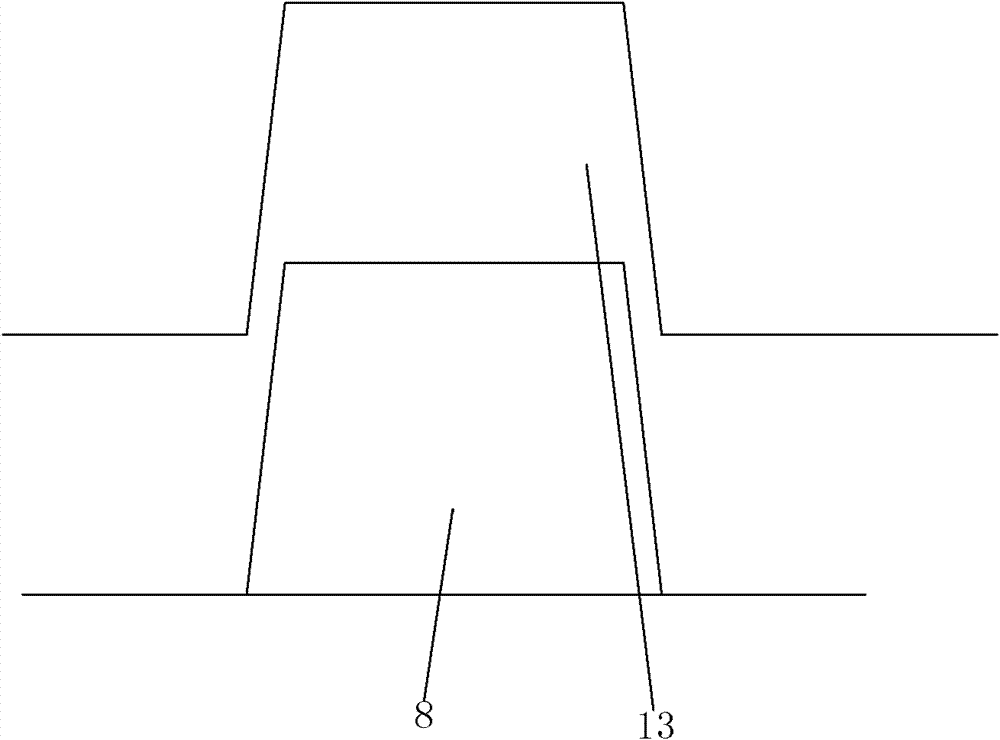

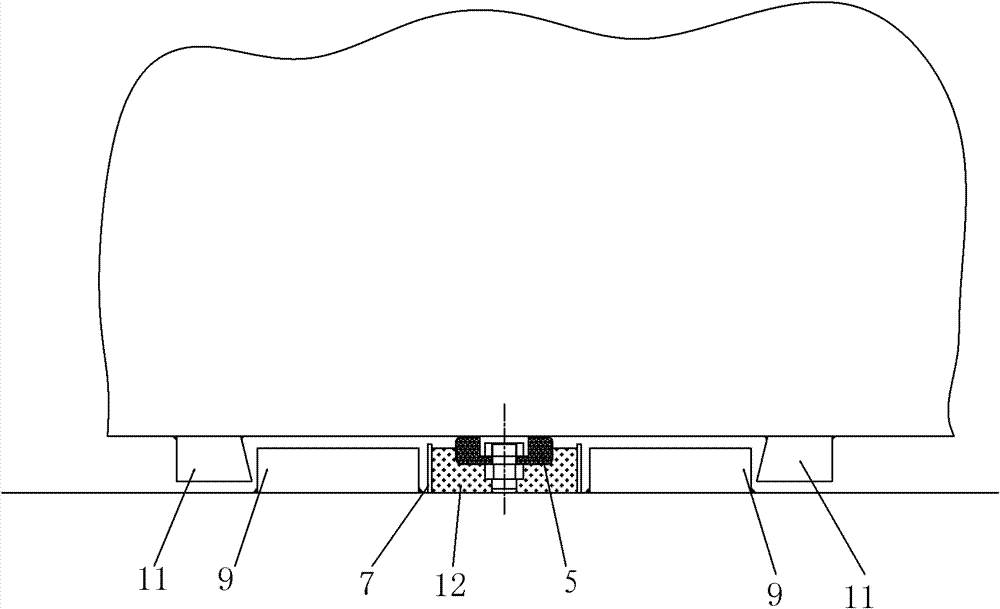

[0054] The present invention will be further described below in conjunction with the accompanying drawings.

[0055] The embodiment only takes the positioning combination of a single cabin and the cargo compartment as an example to illustrate the positioning method of the independent cargo compartment and the hull of the asphalt ship, including the following steps:

[0056] 1. Preparation before horizontal positioning:

[0057] 1) Manufacture the thermal insulation support block (5), the thermal insulation support block frame (7), and the laminated wood (10) respectively according to the designed size; wherein, the thermal insulation support block (5) is made of glass fiber and epoxy resin A rectangular block made of composite material, with a through hole in the middle that allows the guide shaft (6) of the heat insulating support pad to pass through, the upper part of the through hole is larger than the lower part and is a stepped hole; the surrounding frame of the heat insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com