A high-precision error correction method for multiple low-pressure gradient proportional solenoid valves

A technology of proportional solenoid valve and low-pressure gradient, which is applied in the direction of valve operation/release device, valve details, valve device, etc., can solve problems such as difficulty, manpower and material resources, and inability to guarantee, and achieve accurate valve opening and closing time, control The valve opening and closing time, the effect of the same opening and closing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

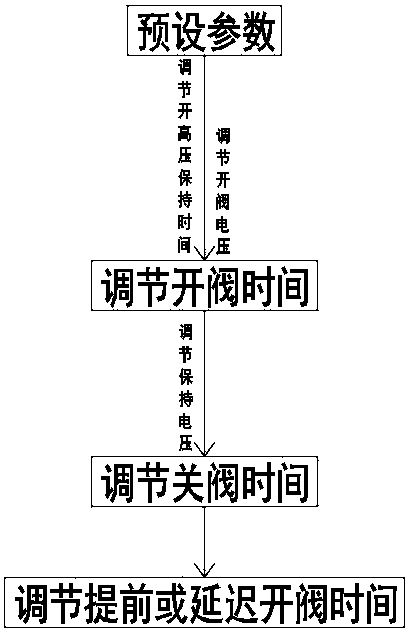

[0029] A high-precision error correction method for multiple low-voltage gradient proportional solenoid valves in this embodiment pre-sets the valve opening voltage, holding voltage, and high voltage holding time parameters of each proportional solenoid valve; the valve opening voltage and holding voltage use Independent DC voltage; the valve opening voltage is set to 1-4 times the rated voltage of the proportional solenoid valve, the holding voltage is set to 1 / 5-1 / 2 of the rated voltage of the proportional solenoid valve, and the high voltage holding The time is set to 1.1-2.5 times of the opening time of the proportional solenoid valve.

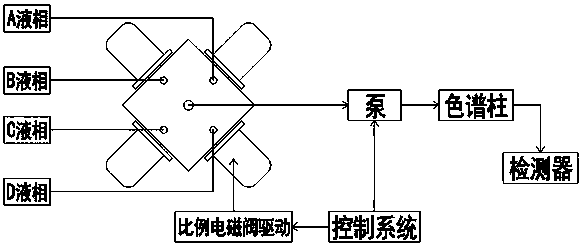

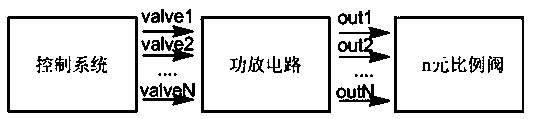

[0030] Use the supporting control system and power amplifier system to control each proportional solenoid valve, and preset and save the valve opening voltage, holding voltage, high voltage holding time, advance valve opening time, and delay opening time for controlling the proportional solenoid valve in the control system. Valve time para...

Embodiment 2

[0036] This embodiment is further optimized on the basis of Embodiment 1. During the liquid inlet process, the opening and closing time of the proportional solenoid valve is controlled so that the proportional solenoid valve is in the open state at any time, thereby eliminating air pumping.

[0037] When mixing various proportions of liquid phases, the opening or closing time of the proportional solenoid valves on each liquid phase flow path is also different according to the required proportion of the liquid phase to be mixed. After the proportional solenoid valve of the flow path is completely closed, the proportional solenoid valve of the other flow path should be fully open immediately. However, in actual situations, because the opening and closing of the proportional solenoid valve takes a certain amount of time to complete, it may appear that after the proportional solenoid valve of one flow path is completely closed, the proportional solenoid valve of the other flow path...

Embodiment 3

[0040] This embodiment is further optimized on the basis of Embodiment 1 or 2. During the liquid inlet process, when the adjacent proportional solenoid valves are closed and opened successively, if the valve opening speed of the proportional solenoid valve is greater than the closing speed, then wait The opened proportional solenoid valve is set with a delay valve opening time, otherwise the valve opening time is set in advance.

[0041] Such as Figure 5 As shown, if the valve opening speed of the proportional solenoid valve is greater than the closing speed, there is T AC = T BO +T m +T d , where T BO is the opening time of the proportional solenoid valve to be opened, T AC is the closing time of the proportional solenoid valve to be closed, T m It is the time when two adjacent proportional solenoid valves have liquid flowing out, T d To delay the valve opening time.

[0042] If the valve opening speed of the proportional solenoid valve is less than the closing speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com