End face wear-resistant elastic composite rotor and elastomer production mold thereof

A composite rotor and elastomer technology, which is used in the components of pumping devices for elastic fluids, rotary piston pumps, liquid fuel engines, etc. Scratches and other problems, to achieve the effect of good transportation effect, simple structure and reduced scuffing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

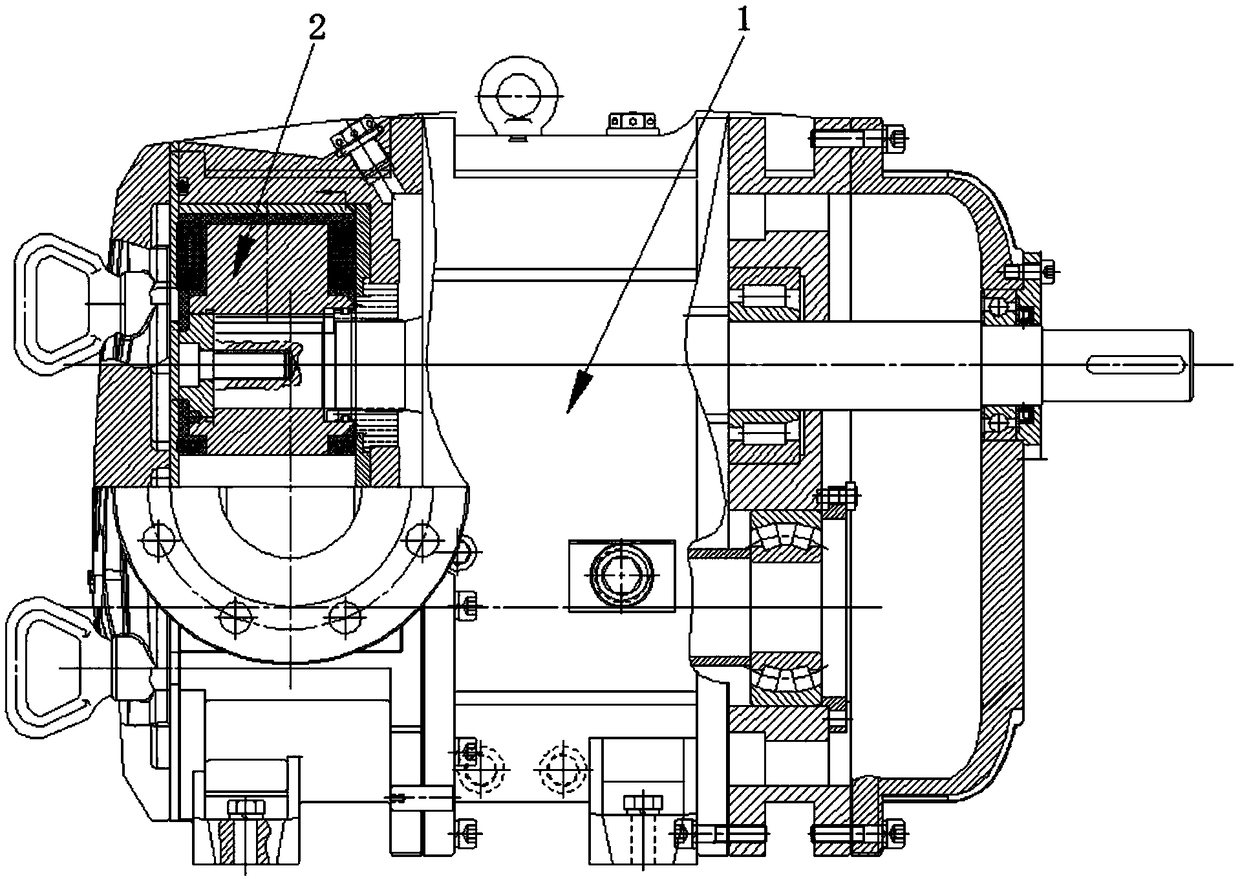

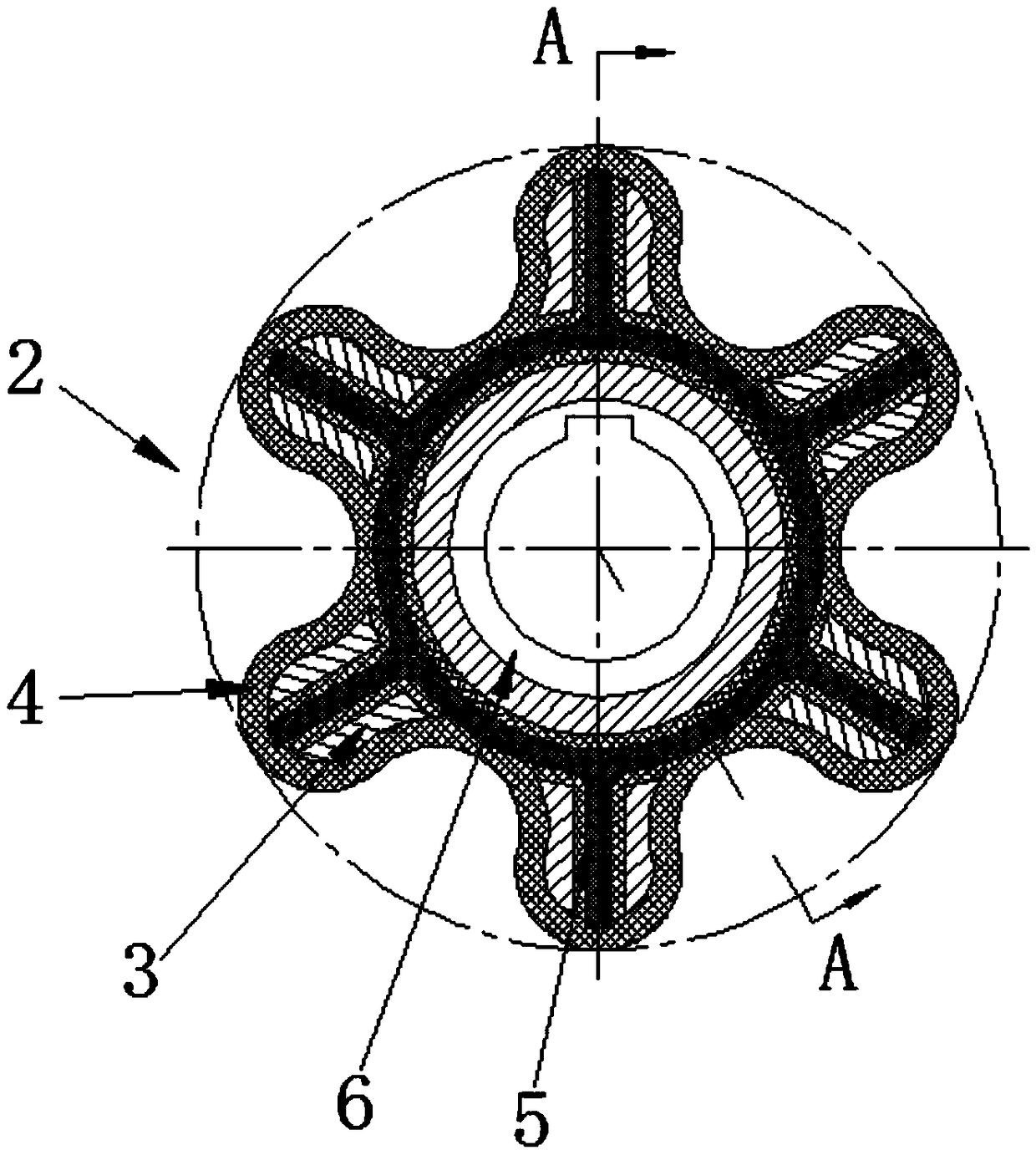

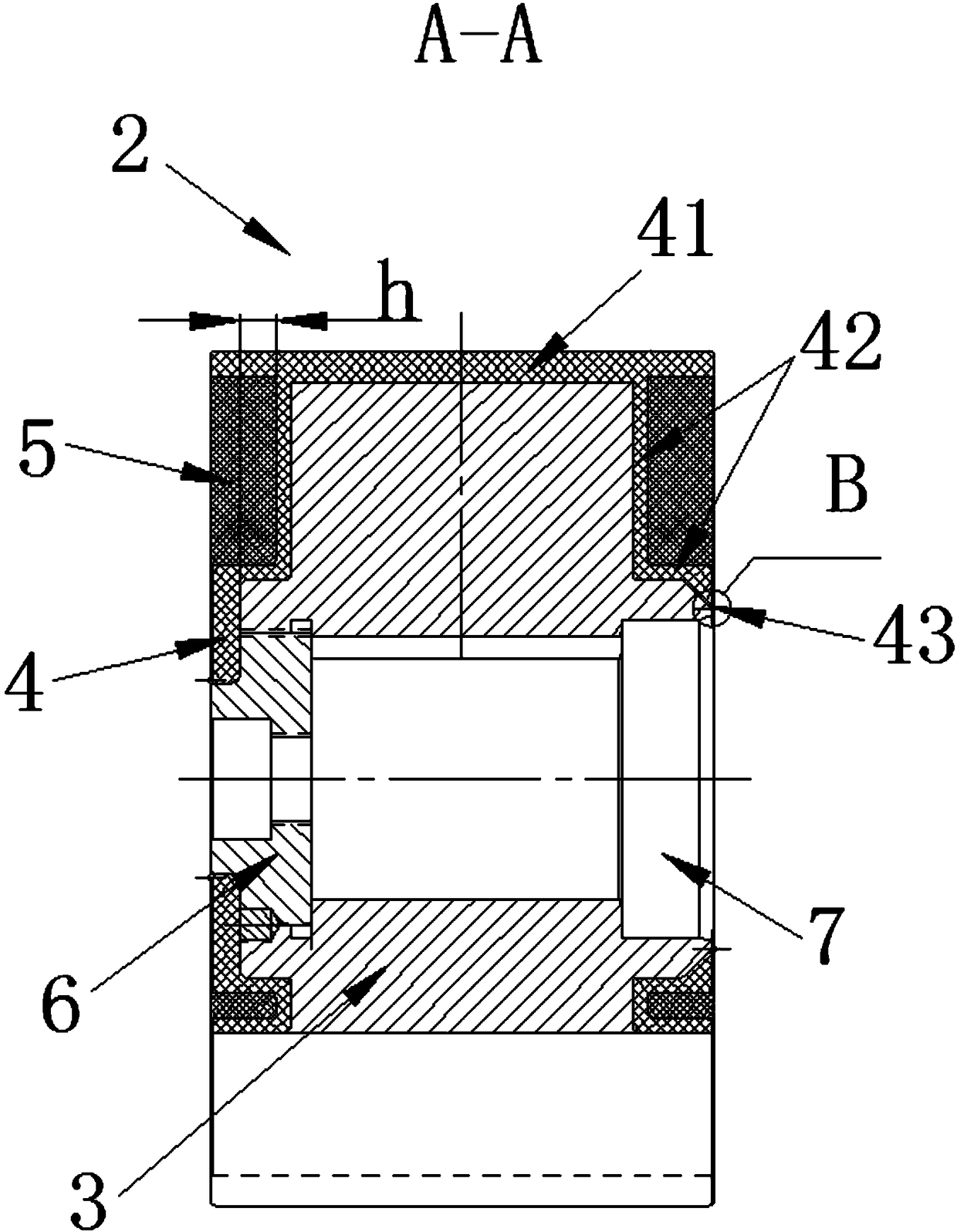

[0027] Refer to Figure 1-Figure 12 , An elastomer rotor of an end face wear-resistant elastic composite rotor of the present invention includes a cam rotor pump 1, an elastomer rotor 2, a support frame 3, an elastomer 4 and a special-shaped end ring 5. The cavity of the cam rotor pump 1 An elastomer rotor 2 is provided. The elastomer rotor 2 includes a support frame 3, an elastic body 4, a special-shaped end face ring 5, a support ring 6 and a movable ring seat hole 7. The support frame 3 is provided with a number of frame blades 31, and both ends of the support frame 3 The end face is provided with a frame groove 32, the outer side of the support frame 3 is provided with an elastic body 4, the end faces of the two ends of the elastic body 4 are provided with a recess 44, and the recess 44 is embedded with a special-shaped end face ring 5;

[0028] The thickness of the rubber side wall 41 of the elastic body 4 is at least 4 mm, and the thickness of the rubber inner side wall 42 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com