A kind of preparation method of planetary reducer grease

A planetary reducer and grease technology, applied in the field of grease, can solve the problems of gear grease leakage, unstable product quality, complex process, etc., and achieve the effects of reducing gear wear, high solid load reaction efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

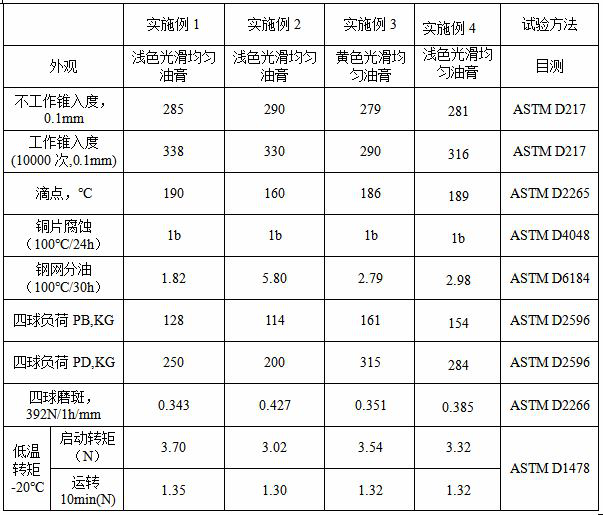

Examples

Embodiment 1

[0042] A preparation method of planetary reducer grease, comprising the steps of:

[0043] (1) In parts by weight, take 20 parts of refined mineral oil, 26.6 parts of polyα-olefin, 6 parts of lauryl hydroxystearic acid and 0.1 part of calcium hydroxide, mix them, heat up to 80°C for 0.5h, and then heat up to 100°C ℃, add 0.6 parts of lithium hydroxide monohydrate for saponification reaction for 2 hours; heat up to 210 ℃ for refining, keep the temperature for 20 minutes;

[0044] (2) After adding 10 parts of refined mineral oil and 13.4 parts of polyα-olefin, quench the temperature to 180°C for thickening, keep the constant temperature for 20 minutes, and carry out dispersing and circulating shearing; further, the quenching adopts a quenching mixer;

[0045] (3) Lower the temperature of the mixture obtained in step (2) to 120°C, add 18 parts of polyisobutylene, 4 parts of extreme pressure antiwear agent, 0.5 part of oxidizing agent, and 0.9 part of rust inhibitor, and stir even...

Embodiment 2

[0063] In this embodiment, a preparation method of grease for a planetary reducer comprises the following steps:

[0064] (1) In parts by weight, take 20 parts of refined mineral oil, 26.6 parts of polyα-olefin, 8 parts of lauryl hydroxystearic acid and 0.9 parts of calcium hydroxide, mix them, heat up to 80°C for 1 hour, and then heat up to 100°C. Add 0.5 lithium hydroxide monohydrate for saponification reaction for 2 hours; heat up to 220°C for refining, keep the temperature for 20 minutes;

[0065] (2) After adding 10 parts of refined mineral oil and 13.4 parts of polyα-olefin, quench the temperature to 170°C for thickening, keep the temperature for 10 minutes, and carry out dispersing and cyclic shearing;

[0066] (3) Lower the temperature of the mixture obtained in step (2) to 120°C, add 17 parts of polyisobutylene, 0.5 part of antioxidant, 3 parts of extreme pressure antiwear agent, and 0.6 part of rust inhibitor, and stir evenly.

[0067] (4) Grinding, homogenizing and...

Embodiment 3

[0084] In this embodiment, a preparation method of grease for a planetary reducer comprises the following steps:

[0085] (1) In parts by weight, take 20 parts of refined mineral oil, 26.6 parts of polyα-olefin, 3 parts of lauryl hydroxystearic acid and 0.58 parts of calcium hydroxide, mix them, heat up to 80°C for 1 hour, and then heat up to 100°C, Add 0.7 parts of lithium hydroxide monohydrate for saponification reaction for 2 hours; heat up to 200°C for refining, keep the temperature for 30 minutes;

[0086] (2) After adding 10 parts of refined mineral oil and 13.4 parts of polyα-olefin, quench the temperature to 175°C for thickening, keep the constant temperature for 10 minutes, and carry out dispersing and cyclic shearing;

[0087] (3) Lower the temperature of the mixture obtained in step (2) to 120°C, add 17 parts of polyisobutylene, 0.25 parts of antioxidant, 4 parts of extreme pressure antiwear agent, and 0.8 part of rust inhibitor, and stir evenly.

[0088] (4) Grind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com