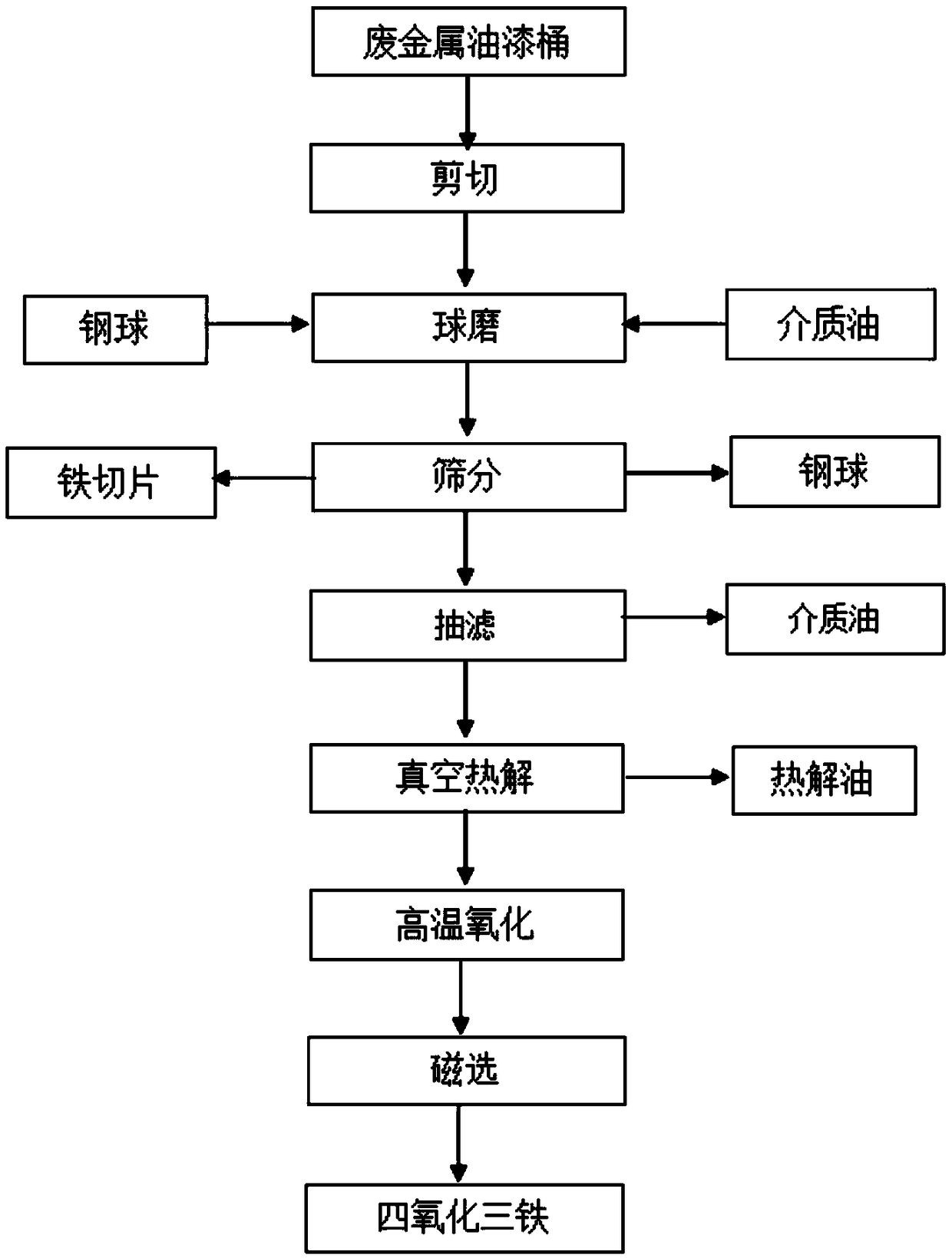

Method for recycling waste metal paint buckets

A technology for recycling and paint buckets, which is applied in the treatment of hydrocarbon oil, petroleum industry, oxides of sub-metallic iron, etc. It can solve the difficult physical peeling of the surface coating and paint of scrap metal paint buckets, difficult manual or mechanical peeling, etc. problem, to achieve the effect of low cost, simple device, and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Use a cutting machine to cut 2Kg scrap iron paint buckets into slices with a size of 50cm×50cm, send the slices into a closed container, and keep the temperature at 40°C for 40min;

[0026] 2) Add the slices obtained in step 1) and 1Kg of steel balls with a diameter of 120mm and 0.1Kg of diesel into a vertical stirring ball mill, and process them at a speed of 200r / min for 10min. The paint coating and a small amount of iron on the surface of the slices are stripped and mixed into the diesel middle;

[0027] 3) The material in the vertical ball mill is taken out and screened to obtain processed slices, steel balls and diesel oil mixed with lacquer coating substances, and the slices are used as raw materials for recycled metals; steel balls are used as the medium for ball mill reuse; The diesel oil mixed with iron powder and lacquer coating substance is subjected to suction filtration treatment, and the obtained diesel oil is reused as a buffer for ball milling materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com