Solvent-free epoxy internal drag reducing coating

A solvent-free, epoxy-based technology, applied in epoxy resin coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve problems such as poor light stability, achieve enhanced coating film performance, enhanced mechanical force and coating performance, and facilitate construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

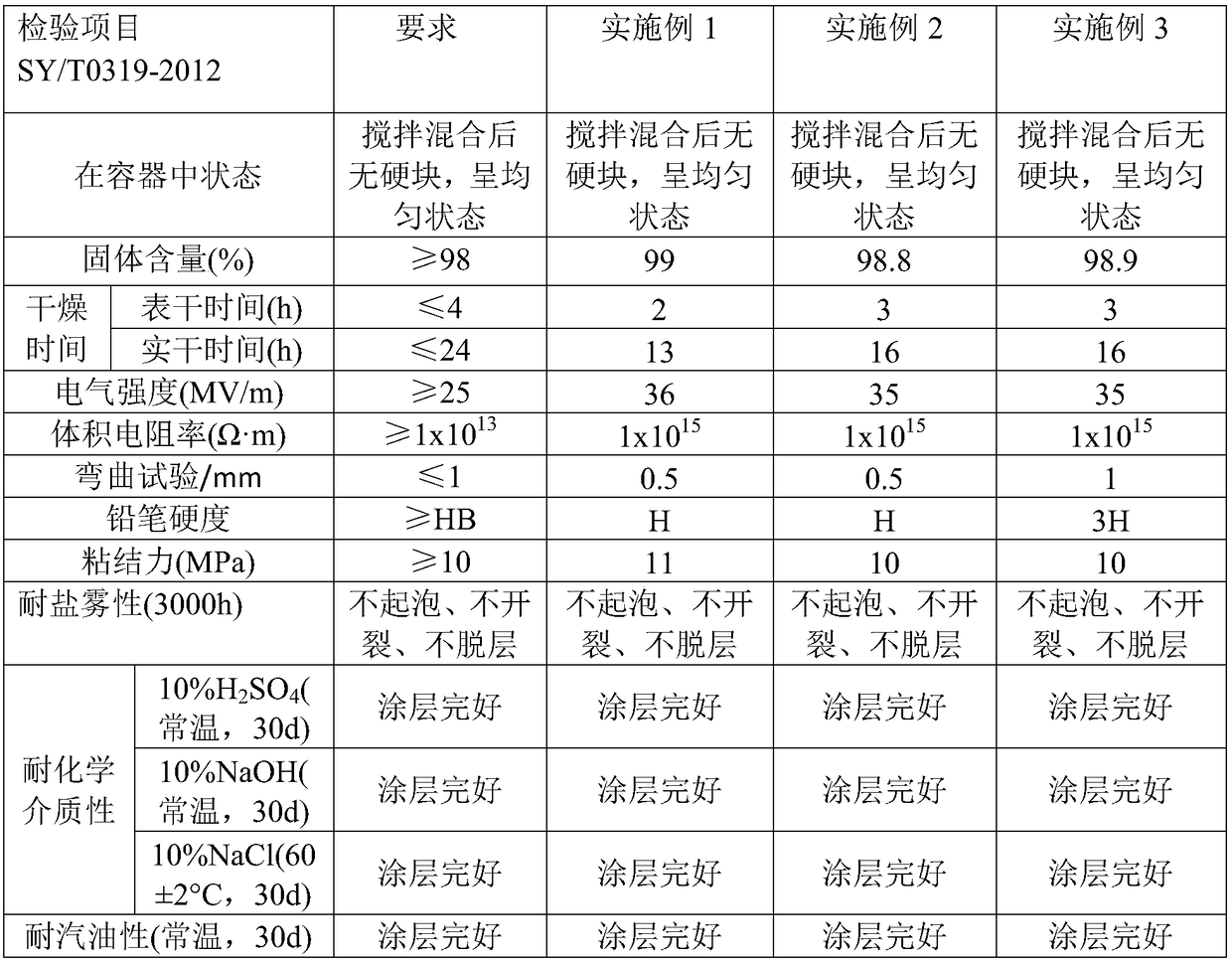

Examples

Embodiment 1

[0029] A solvent-free epoxy internal drag-reducing coating, including a main agent and a curing agent. The mass ratio of the main agent and curing agent is 4:1.

[0030] The main agent includes the following components in parts by weight: 38.0 parts of epoxy resin, 7.25 parts of epoxy diluent, 1.72 parts of anti-sedimentation aid, 5.0-15.0 parts of iron oxide red, 22.63 parts of 400 mesh talcum powder, 21.87 parts of superfine barium sulfate, 0.5 parts of defoaming agent, 0.72 parts of leveling agent, and 2.31 parts of sagging aid. The curing agent includes the following components in parts by weight: 50.0 parts of E-3034, 2.70 parts of epoxy resin accelerator, and 47.3 parts of xylene.

[0031] The main agent is prepared by the method comprising the following steps:

[0032] Step 1: Add 38.0 parts of epoxy resin, 2.0 parts of epoxy diluent, and 1.72 parts of anti-sedimentation aid talcum powder into the reaction kettle in turn, and stir at a high speed to obtain a mixed sol...

Embodiment 2

[0039] A solvent-free epoxy internal drag-reducing coating, including a main agent and a curing agent. The mass ratio of the main agent and curing agent is 5:1.

[0040] The main agent includes the following components in parts by weight: 41.44 parts of epoxy resin, 18.59 parts of epoxy diluent, 0.24 parts of anti-sedimentation aid, 15.0 parts of iron oxide red, 12.87 parts of 400 mesh talc powder, superfine 10.85 parts of barium sulfate, 0.1 parts of defoaming agent, 0.28 parts of leveling agent, and 0.63 parts of sagging aid. The curing agent includes the following components in parts by weight: 62.5 parts of E-3034, 2.70 parts of epoxy resin accelerator, and 34.8 parts of xylene.

[0041] The main agent is prepared by the method comprising the following steps:

[0042] Step 1: Add 41.44 parts of epoxy resin, 8.81 parts of epoxy thinner, and 0.24 parts of anti-sedimentation aid talcum powder into the reaction kettle in turn, and stir at a high speed to obtain a mixed solut...

Embodiment 3

[0049] A solvent-free epoxy internal drag-reducing coating, including a main agent and a curing agent. The mass ratio of the main agent and curing agent is 5:1.

[0050]The main agent includes the following components in parts by weight: 46.0 parts of epoxy resin, 4.6 parts of epoxy diluent, 1.0 parts of anti-sedimentation aid, 12.0 parts of iron oxide red, 19.12 parts of 400 mesh talcum powder, superfine 15.0 parts of barium sulfate, 0.3 parts of defoaming agent, 0.48 parts of leveling agent, and 1.5 parts of sagging aid. The curing agent includes the following components in parts by weight: 58.5 parts of E-3034, 2.0 parts of epoxy resin accelerator, and 39.5 parts of xylene.

[0051] The main agent is prepared by the method comprising the following steps:

[0052] Step 1: Add 46.0 parts of epoxy resin, 4.0 parts of epoxy diluent, and 1.0 part of anti-sedimentation aid talcum powder into the reaction kettle in sequence, and perform high-speed stirring to obtain a mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com