A kind of asphalt regenerant and preparation method thereof

An asphalt rejuvenator and asphalt regeneration technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor long-term stability of waste asphalt, and achieve the effect of improving self-stability, stability, and recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

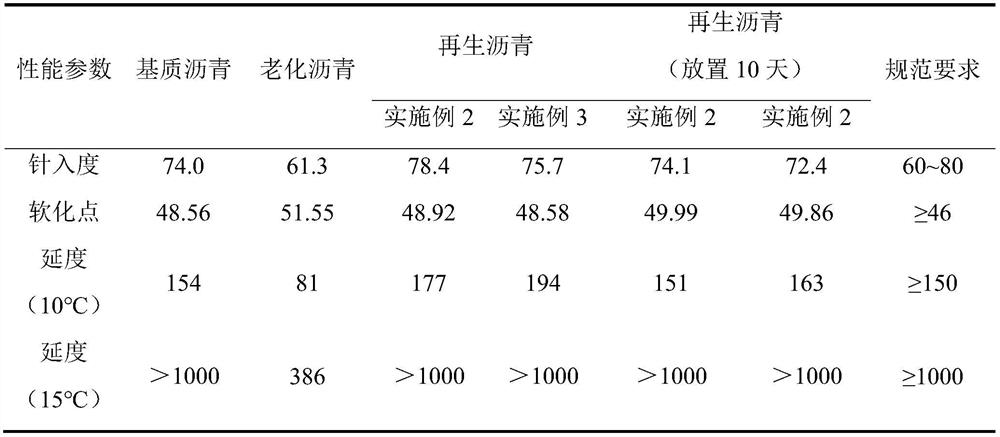

Examples

Embodiment 1

[0026] An asphalt rejuvenator, in parts by weight, the asphalt rejuvenator is composed of 45-55 parts of base oil, 20-30 parts of aromatic light oil, and 20-30 parts of plasticizer; of waste engine oil. Among them, the waste engine oil can be at least one of the waste engine oil in domestic automobile engines, the waste engine oil in motorcycle engines, and the mixed waste engine oil of different brands left over from automobile 4s shops or auto repair factories; the aromatic light oil is furfural Extraction oil, which is a by-product of the lube base oil manufacturing process.

[0027] The asphalt rejuvenator of this embodiment pretreats the waste engine oil as the base oil by heating, cooling, filtering and other processes to remove water, light components, residues, etc., so as to improve the stability of the waste engine oil, thereby improving The stability of the asphalt rejuvenator prepared in this example, when the asphalt rejuvenator prepared in this example is used f...

Embodiment 2

[0032] A kind of asphalt regenerant, specifically prepare through the following steps:

[0033] 1) Put the waste engine oil into a reaction kettle with a temperature of 190°C, heat it, and stir it at a speed of 700r / min for 60 minutes during the heating process, then cool the waste engine oil to room temperature, and use a 2.0 micron microporous filter membrane Filter the cooled waste engine oil to obtain base oil;

[0034] 2) Add 50 parts of base oil into the reactor and gradually raise the temperature to 135°C, then add 25 parts of furfural to extract the oil, and stir at a speed of 700r / min for 10 minutes to obtain asphalt regenerated oil;

[0035] 3) Add 20 parts of component A to the asphalt regenerated oil, stir for 10 minutes at a speed of 1000r / min, then add 5 parts of component B, continue stirring for 10 minutes at a speed of 1000r / min, after stirring, cool to room temperature to obtain the asphalt regenerant of this embodiment.

Embodiment 3

[0037] A kind of asphalt regenerant, specifically prepare through the following steps:

[0038] 1) Put the waste engine oil into the reaction kettle with a temperature of 195°C, heat it, and stir it at a speed of 700r / min for 60 minutes during the heating process, then cool the waste engine oil to room temperature, and use a 2.0 micron microporous filter membrane Filter the cooled waste engine oil to obtain base oil;

[0039] 2) Add 40 parts of base oil into the reactor and gradually raise the temperature to 140°C, then add 35 parts of furfural to extract the oil, and stir at a speed of 700r / min for 10 minutes to obtain asphalt regenerated oil;

[0040] 3) Add 20 parts of component A to the asphalt regenerated oil, stir for 10 minutes at a speed of 1000r / min, then add 5 parts of component B, continue stirring for 10 minutes at a speed of 1000r / min, after stirring, cool to room temperature to obtain the asphalt regenerant of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com