Separation method and system for mixture of ethanol, diphenyl carbonate and diphenyl carbonate

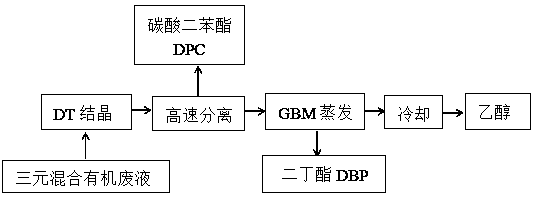

A diphenyl carbonate and separation method technology, which is applied in the separation of dibutyl mixed organic matter, ethanol, and diphenyl carbonate, can solve the problems of ternary organic waste liquid separation difficulties, high vacuum, and environmental pollution, and achieve Easy to control, low temperature, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0066] will be 1.5m 3 The ternary mixed organic waste liquid of ethanol, DPC and DBP produced in the membrane industry, at a temperature of 60°C, is pumped into the DT crystallizer through a constant temperature pipeline, and the stirring speed is controlled at 45r.min -1 , turn on the cooling liquid circulation cooling, generally the temperature of the cooling crystallization material is controlled at 8 ° C, the cooling time is 4 hours, and then pumped into the centrifuge with a separation factor of 1000 for separation, the weight of DPC obtained is 65 kg, and the content of DPC is detected after drying 99.5%, can be returned to use;

[0067] The separated liquid is poured into the GMB evaporator for evaporation. The temperature in the GMB evaporator is controlled at 80°C, the frequency of the feed pump is 20Hz, the vapor pressure is 0.3MPa, and 1.3m is obtained by continuous evaporation for 3 hours. 3 The ethanol solution, after checking that the main content of ethanol is ...

example 2

[0070] will be 1.5m 3 The ternary mixed organic waste liquid of ethanol, DPC and DBP produced in the film industry, at a temperature of 65°C, is pumped into the DT crystallizer through a constant temperature pipeline, and the stirring speed is controlled to 30r.min -1 , Turn on the cooling liquid circulation cooling, generally the temperature of the cooling crystallization material is controlled at 15°C, the cooling time is 2.5hr, and then pumped into the centrifuge with a separation factor of 1300 for separation, the weight of DPC obtained is 64.5kg, and the DPC is detected after drying The content is 99.4%, which can be returned for use;

[0071] The separated liquid is poured into the GMB evaporator for evaporation. The temperature in the GMB evaporator is controlled at 82°C, the frequency of the feed pump is 25Hz, the vapor pressure is 0.2MPa, and 1.35m is obtained by continuous evaporation for 3 hours. 3 The ethanol solution, after checking that the main content of ethan...

example 3

[0074] will be 1.5m 3 The ternary mixed organic waste liquid of ethanol, DPC and DBP produced in the membrane industry, at a temperature of 62°C, is pumped into the DT crystallizer through a constant temperature pipeline, and the stirring speed is controlled at 60r.min -1 , turn on the cooling liquid circulation cooling, generally the temperature of the cooling crystallization material is controlled at 20°C, the cooling time is 4.5hr, and then pumped into a centrifuge with high separation factor for separation, the weight of DPC obtained is 63.8kg, and the DPC is detected after drying The content is 99.3%, which can be returned for use;

[0075] The separated liquid is poured into the GMB evaporator for evaporation. The temperature in the GMB evaporator is controlled at 81°C, the frequency of the feed pump is 22Hz, the vapor pressure is 0.25MPa, and 1.28 m is obtained by continuous evaporation for 3 hours. 3 The ethanol solution, after checking that the main content of ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com