New anaerobic reactor for treating landfill leachate wastewater

An anaerobic reactor and landfill leachate technology, applied in the treatment of polluted groundwater/leachate, water/sewage treatment, biological water/sewage treatment, etc., can solve the problem of high construction cost, low biogas yield, reactor Problems such as difficulty in maintenance and overhaul can improve the efficiency of biogas collection, increase the biochemical reaction, and reduce the dead zone and short flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

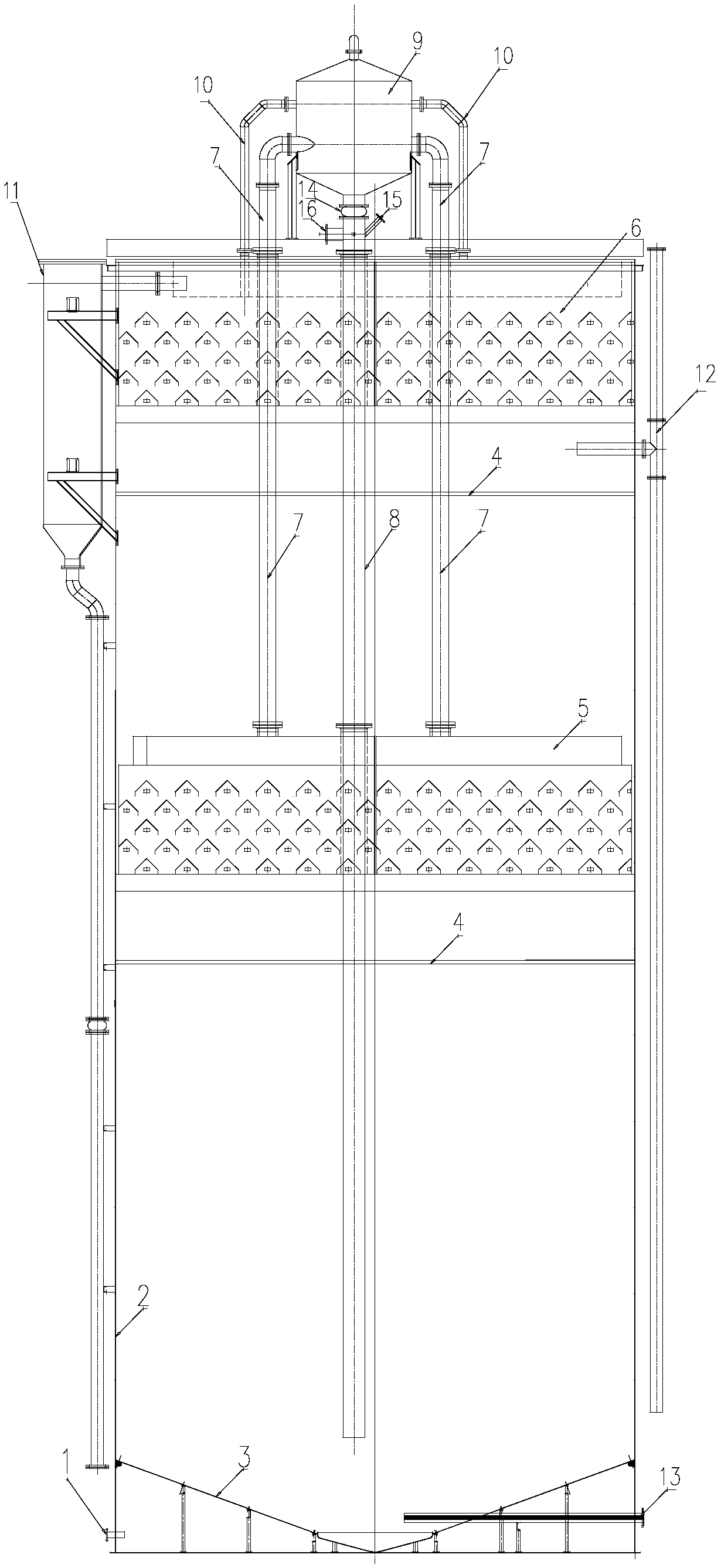

[0024] Example: refer to figure 1 As shown, it includes an anaerobic reactor and a computer automatic monitoring system. The computer automatic monitoring system is connected to the control of the anaerobic reactor. The temperature and flow of the anaerobic reactor are controlled by the computer automatic monitoring system. The anaerobic reactor described therein consists of a water inlet pipe 1, a steel structure tank body 2, a water distribution sand settling plate 3, a steel structure platform 4, a first layer of deflector separator 5, and a second layer of deflector separator 6 , The first layer of deflector separator biogas riser 7, internal circulation return pipe 8, biogas dehydrator 9, the second layer of deflector separator biogas riser 10, outlet pipe 11, outer circulation pipe 12 and sand discharge pipe Composed of 13, the left and right sides of the steel structure tank body 2 are connected with water inlet pipes 1 and sand discharge pipes 13 correspondingly, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com