Lithium battery electrode slurry stirring processing method and lithium battery electrode slurry obtained by processing

A technology of electrode slurry and processing method, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve problems such as difficulty in stirring evenly, prolong battery cycle, and adversely affect battery performance, and achieve uniform slurry and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

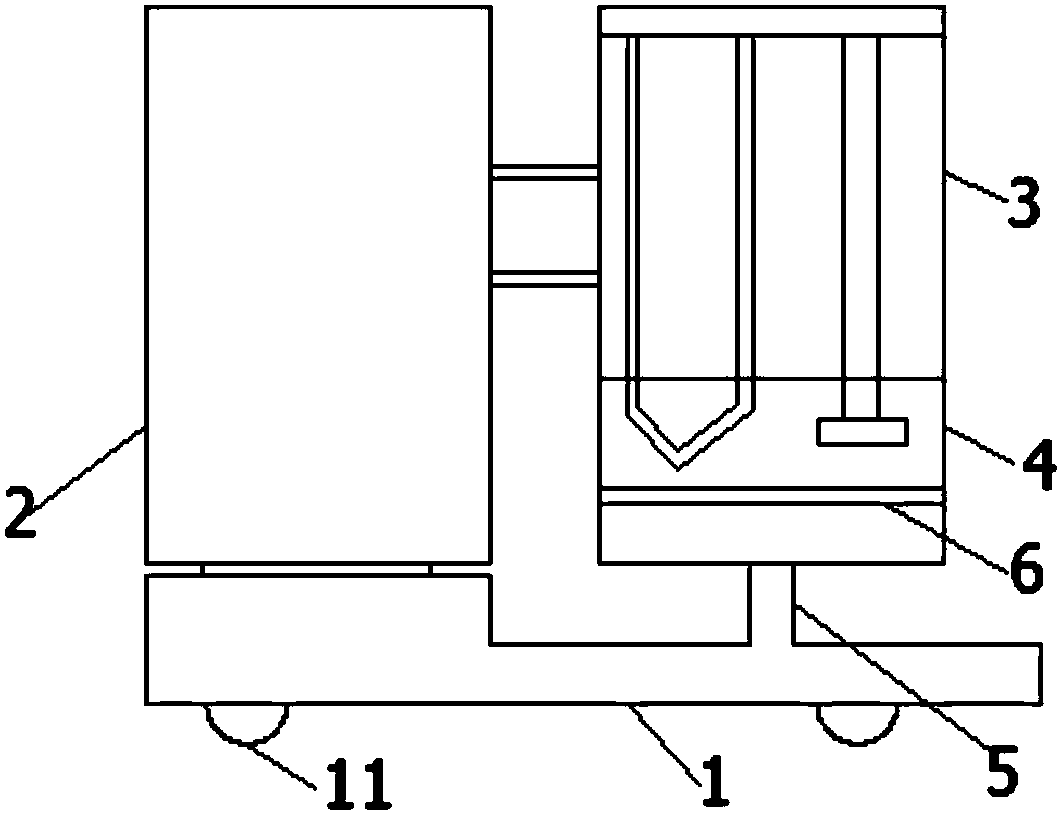

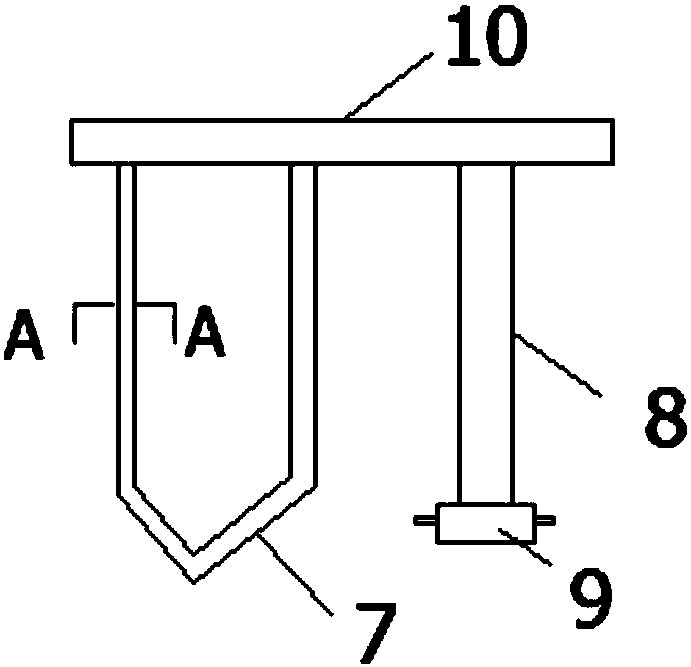

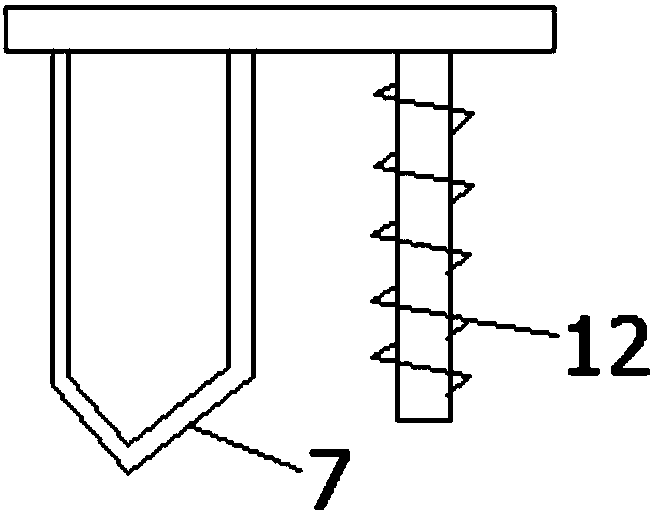

Method used

Image

Examples

Embodiment 1

[0074] A stirring processing method for lithium battery electrode slurry, comprising the following steps: (a) premixing: mixing the solvent NMP and the binder PVDF uniformly to obtain the first mixture, and mixing the active material lithium iron phosphate and the conductive agent KS-6 conductive graphite Mix well to get the second mixture;

[0075] (b) primary stirring: 25% of the first mixture and all the second mixture are mixed and stirred to obtain the third mixture, the stirring rate is 5r / min, and the stirring time is 3min;

[0076] (c) secondary stirring: mixing and stirring the remaining first mixture and all the third mixture, the stirring rate is 20r / min, and the stirring time is 15min;

[0077] (d) stirring three times: the stirring speed is 40r / min, and the stirring time is 35min;

[0078] (e) stirring four times: the stirring speed is 90r / min, and the stirring time is 15min;

[0079] (f) Stir five times: the stirring rate is 40r / min, and the stirring time is 35...

Embodiment 2

[0083] A stirring processing method for lithium battery electrode slurry, comprising the following steps: (a) pre-mixing: mixing the solvent NMP and the binder PVDF uniformly to obtain the first mixture, and mixing the active material lithium iron phosphate and the conductive agent KS-6 conductive graphite Mix well to get the second mixture;

[0084] (b) primary stirring: 35% of the first mixture and all the second mixture are mixed and stirred to obtain the third mixture, the stirring speed is 8r / min, and the stirring time is 5min;

[0085] (c) secondary stirring: mixing and stirring the remaining first mixture and all the third mixture, the stirring rate is 20r / min, and the stirring time is 3min;

[0086] (d) stirring three times: the stirring speed is 60r / min, and the stirring time is 10min;

[0087] (e) stirring four times: the stirring speed is 100r / min, and the stirring time is 20min;

[0088](f) Stir five times: the stirring rate is 60r / min, and the stirring time is 1...

Embodiment 3

[0092] A stirring processing method for lithium battery electrode slurry, comprising the following steps: (a) premixing: mixing the solvent NMP and the binder PVDF uniformly to obtain the first mixture, and mixing the active material lithium iron phosphate and the conductive agent KS-6 conductive graphite Mix well to get the second mixture;

[0093] (b) primary stirring: 50% of the first mixture and all the second mixture are mixed and stirred to obtain the third mixture, the stirring speed is 15r / min, and the stirring time is 20min;

[0094] (c) secondary stirring: mixing and stirring the remaining first mixture and all the third mixture, the stirring rate is 30r / min, and the stirring time is 10min;

[0095] (d) stirring three times: the stirring rate is 80r / min, and the stirring time is 30min;

[0096] (e) stirring four times: the stirring speed is 120r / min, and the stirring time is 50min;

[0097] (f) Stir five times: the stirring rate is 80r / min, and the stirring time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com