Side wall type plate discharging machine applied to printed circuit board

A technology for printed circuit boards and board placement machines, which is used in cleaning methods using gas flow, conveyors, destacking of objects, etc. effect of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

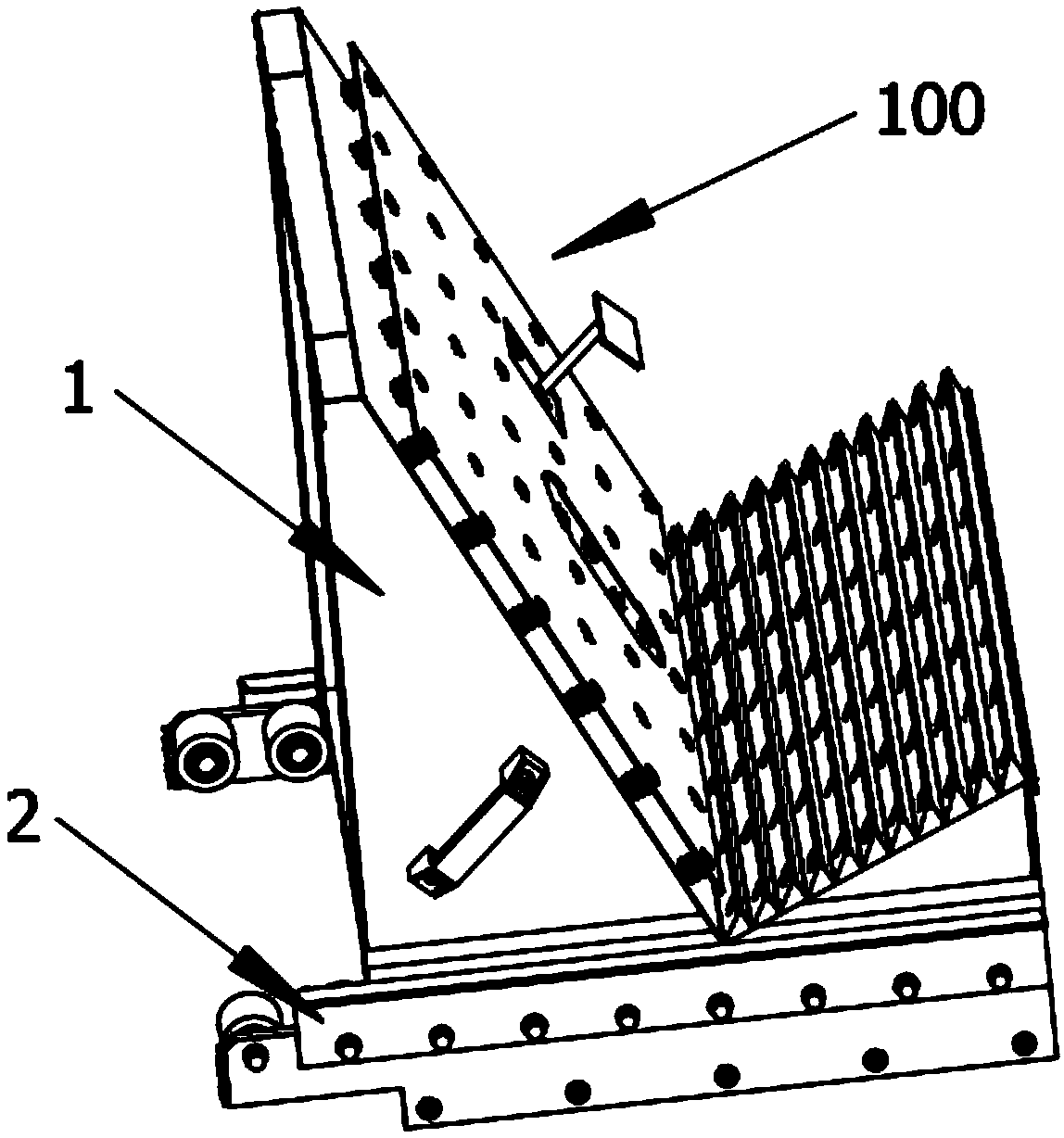

[0069] Embodiment: a kind of side wall type board machine that is applied to the printed circuit board, as Figure 1-Figure 17 As shown, it includes a frame and a feeding mechanism 100 fixed on the frame, a grabbing mechanism 200, a feeding mechanism 300, a dust removal mechanism 400 and an electric control box;

[0070] The feeding mechanism includes an "L"-shaped backplane frame 1 for placing materials and a support wheel set 2 that supports the backplane frame to reciprocate on the frame, and the support wheel set includes rollers symmetrically fixed on the frame group, the backboard frame can move back and forth relative to the roller group;

[0071] The backboard frame includes a backboard 11 and a lower support plate 12, the acute angle formed between the backboard and the horizontal line is 60-70°, and the acute angle formed between the lower support plate and the horizontal line is 20-30° °, the backboard has a resisting structure and an insulating plate 17 for resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com