R corner too large size repairing device

A technology with large size and slot placement, which is used in grinding/polishing safety devices, grinding workpiece supports, grinding machines, etc. It can solve the problem of not being able to repair bilateral or two R angles at the same time, and unable to meet the simultaneous repair of two R angles. , to achieve the effect of convenient and sufficient energy saving, ensuring safety and high efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

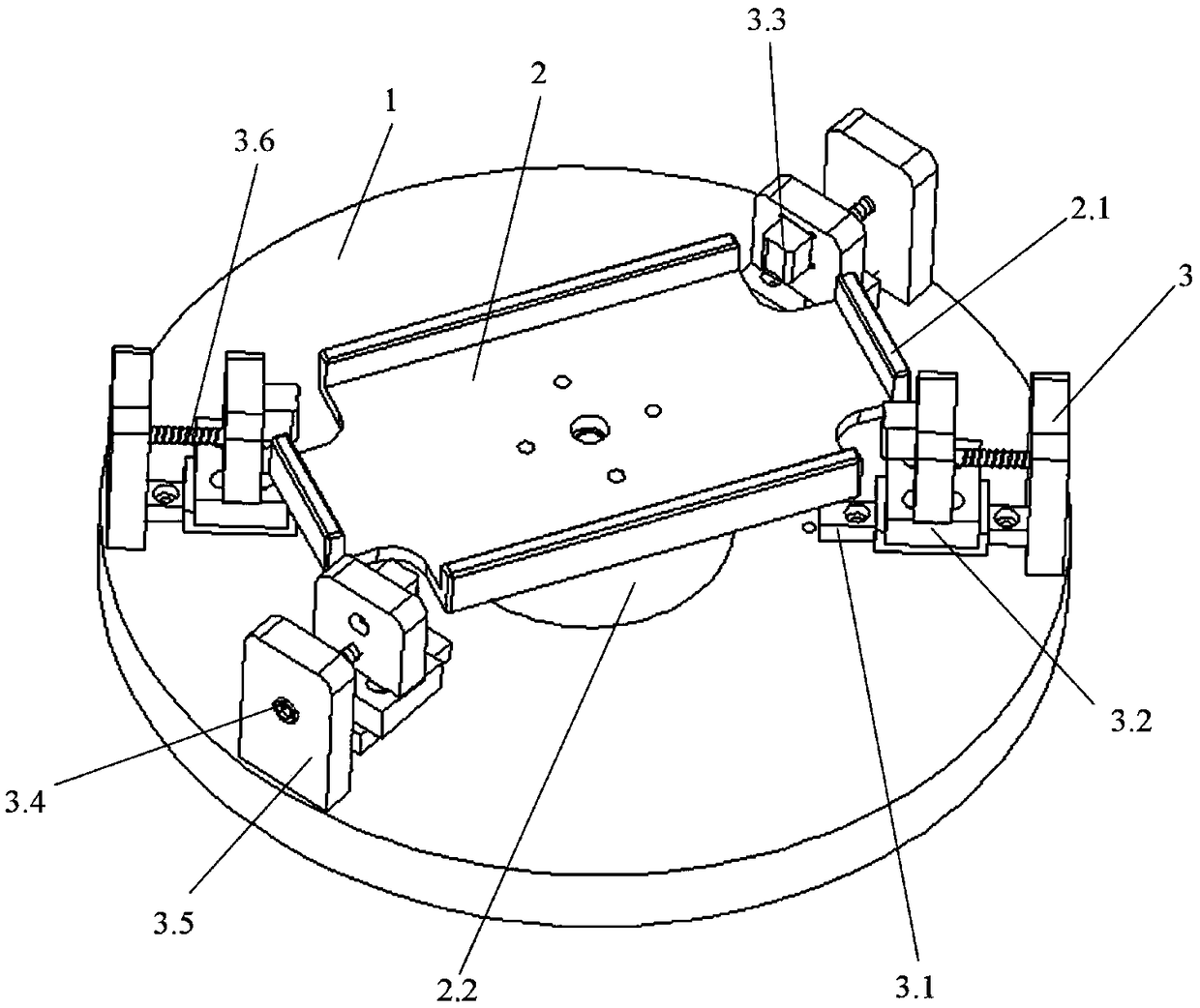

[0033] see figure 1, a repairing device with a large R angle, including a chassis 1, a product fixing assembly 2 and a grinding wheel grinding assembly arranged on the chassis 1; the product fixing assembly 2 includes a product placement groove 2.1 and a rotating disk 2.2 arranged up and down and The two are connected by bolts. The rotating disk 2.2 is rotatably arranged on the chassis 1 and can drive the product placement slot 2.1 to rotate relative to the chassis 1. The product placement slot 2.1 has a square structure and is at its R angle position. A notch is provided at the position so that the R angle can be exposed after the product is put in, and it is convenient to repair the R angle of the product; Grinding wheel grinding part 3, described grinding wheel grinding part 3 comprises the slide rail 3.1 that horizontal welding is arranged on the chassis 1 and the length direction faces the R angle notch, the sliding part 3.2 that is slidably arranged on the sliding rail 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com