Metal nano-cluster doped memristor and method for preparing same

A metal nanocluster and memristor technology, applied in the field of microelectronics, can solve the problems of poor retention characteristics, slow erasing and writing speed, and poor cycle tolerance, and achieve fast erasing and writing speed, low switching voltage, and good memristive switching effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

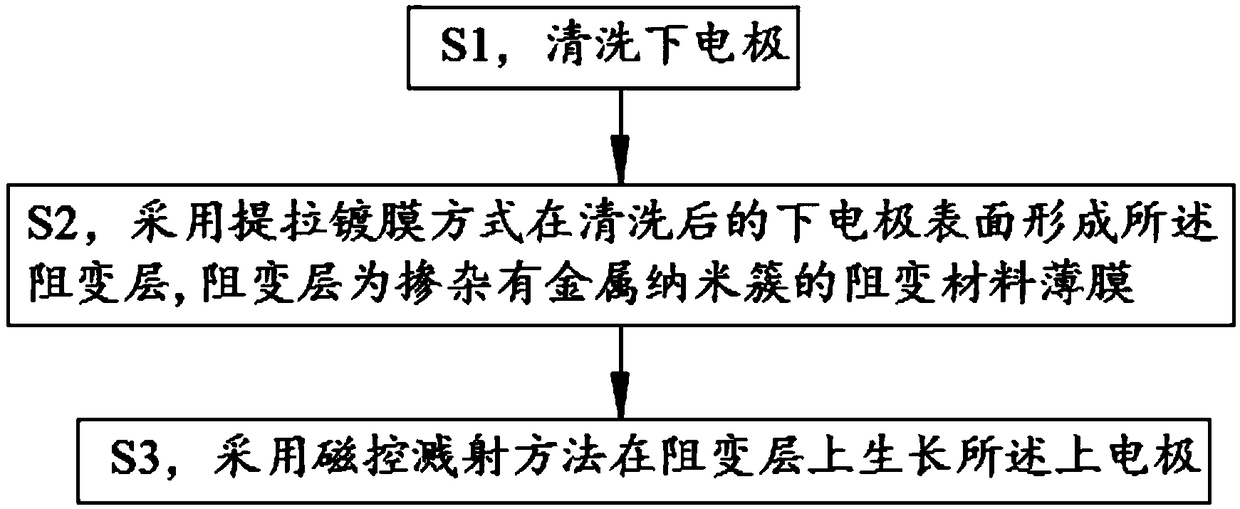

[0033] The present invention also proposes a method for preparing the above-mentioned memristor doped with metal nanoclusters, which includes:

[0034] S1, cleaning the lower electrode;

[0035] S2, forming the resistive layer on the surface of the lower electrode after cleaning by using a pull-coating method;

[0036] S3, growing the upper electrode on the resistive layer by using a magnetron sputtering method.

[0037] In step S1, using the ITO conductive glass to clean refers to decontaminating the ITO conductive glass, for example, immersing it in an organic solution such as acetone for ultrasonic cleaning.

[0038] In step S2, the step of forming the resistive layer on the surface of the lower electrode after cleaning by means of pulling coating includes:

[0039] S21, preparing a natural protein solution. Specific steps include:

[0040] (1) Put the natural silkworm cocoons in a weak alkali solution (such as 3-5 g / L sodium bicarbonate solution), heat and boil for 20-...

Embodiment 1

[0054] This embodiment provides a gold nanocluster doped memristor, which is prepared according to the following steps:

[0055] (1) Cleaning of the lower electrode:

[0056] ITO conductive glass (size 1*4cm, thickness 180nm) was immersed in ultrapure water, acetone, and isopropanol solutions in sequence, ultrasonicated for 10 minutes respectively, and dried with nitrogen to obtain a clean lower electrode.

[0057] (2) Configure silk fibroin solution:

[0058] Take 10g of silkworm cocoons, cut them into pieces, remove impurities, pour them into the prepared weak alkali solution (10g of sodium bicarbonate dissolved in 2L of deionized water), heat to boiling, keep for 30min, repeat 2 times. Take out the silk and soak it in distilled water for 1 hour, during which time the water is changed once. Finally, it is placed in a 60°C oven for drying to obtain degummed silk. Take 5 g of degummed silk, add 35 ml of LiBr solution (9.3 mol / L) to dissolve, and prepare a silk fibroin mixtu...

Embodiment 2

[0070] This embodiment provides a memristor doped with silver nanoclusters, which differs from Embodiment 1 in that: in step (3):

[0071] Measure 24mL bovine serum albumin solution (74mg / mL), configure 48mL silver nitrate solution (7.5mM), mix and stir the two at a stirring speed of 1000rpm, pass in nitrogen, control the temperature at 37°C, add 2.4mL after stirring for 2 minutes Sodium hydroxide solution (1M), after timing the reaction for half an hour, add 1.8mL sodium borohydride solution (112mM), continue the reaction for 1h, and then dialyze with a dialysis bag (solarbio MD80, molecular weight cut-off 8000) for three days to prepare silver nano cluster.

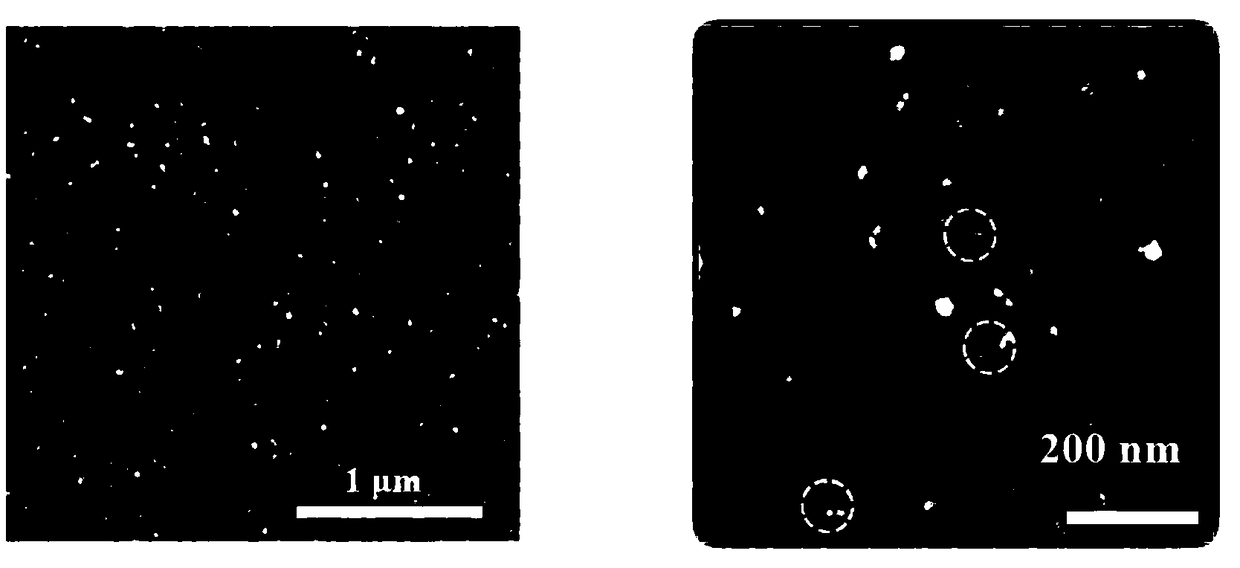

[0072] Such as Figure 4 a shows the atomic force scanning electron microscope image of the silk fibroin film doped with bovine serum of this embodiment and wrapped with gold nanoclusters, Figure 4 b for Figure 4 a Corresponding surface potential scans. Figure 5 for Figure 4 a and Figure 4 b Surface potential...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com