Method for monitoring impact state of cold heading forming machine die

A molding machine and mold technology, applied in impact testing, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as masking, achieve accurate extraction, avoid false components, and avoid modal aliasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

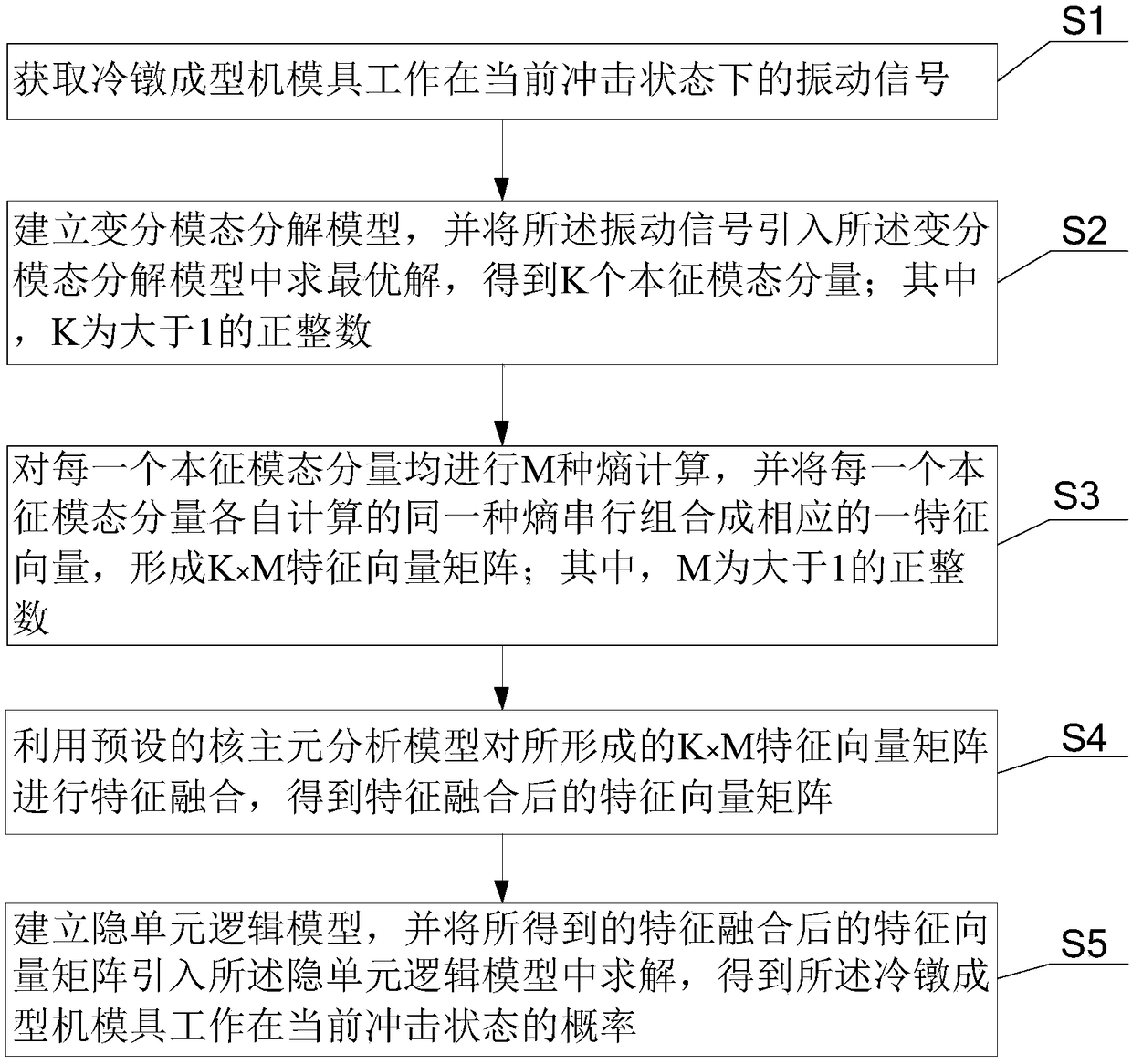

[0036] Such as figure 1 As shown, in the embodiment of the present invention, a method for monitoring the impact state of the mold of a cold heading forming machine is proposed, which includes the following steps:

[0037] Step S1, obtaining the vibration signal of the mold of the cold heading forming machine working under the current impact state;

[0038] The specific process is to obtain the state signal of the real cold heading machine mold when it is working. Different vibration signals can be collected according to different impact states. The collected vibration signals will carry relevant impact data (such as high noise). For example, there are six different impact states of the cold heading forming machine mold that can be collected, including the eccent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com