Water-resistant butterfly valve and method for low-lying position of large-fall oil conveying pipeline

An oil pipeline, anti-shock technology, applied in the directions of lift valves, valve details, valve devices, etc., can solve problems such as excessive valve stem rotation speed and limit valve stem transmission speed, so as to reduce the amount of force applied and prevent the phenomenon of water hammer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

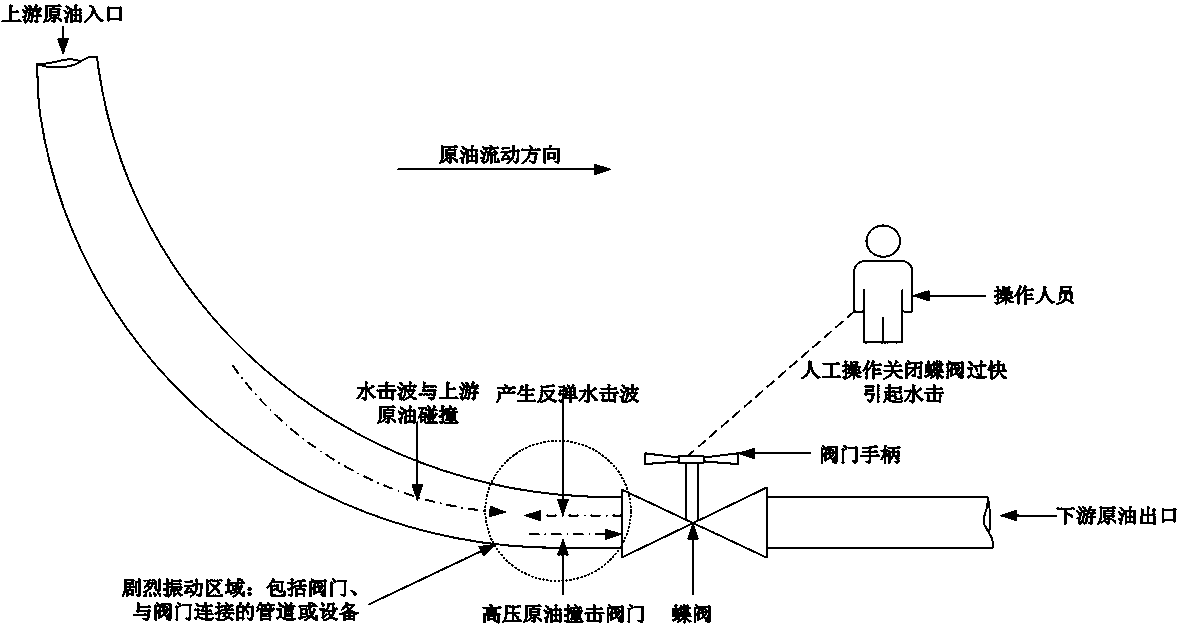

[0042] In this example, figure 1Schematic diagram of water hammer caused by too fast closing of the butterfly valve in the low-lying part of the large-drop oil pipeline. The operator closes the butterfly valve in the low-lying place too quickly, causing the high-pressure crude oil to impact the butterfly valve disc in a short time, resulting in a rebound water shock wave, which collides with the upstream high-pressure crude oil, resulting in a sharp change in the flow rate of crude oil in the pipeline and a sharp fluctuation in the pressure in the pipeline, making the pipeline and pipeline Violent vibration of equipment can easily cause overpressure of pipelines and equipment damage and induce safety accidents, which must be paid enough attention to.

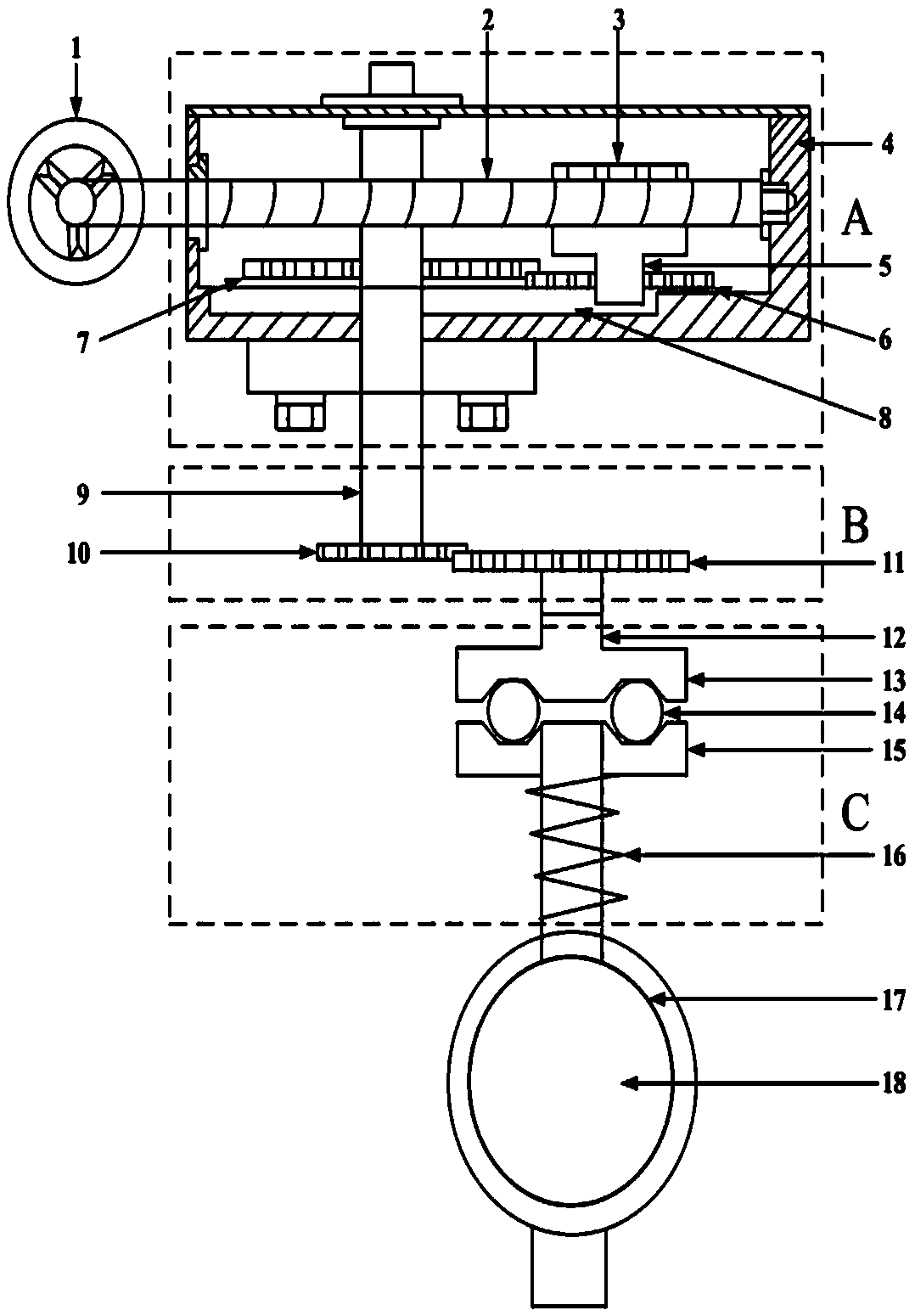

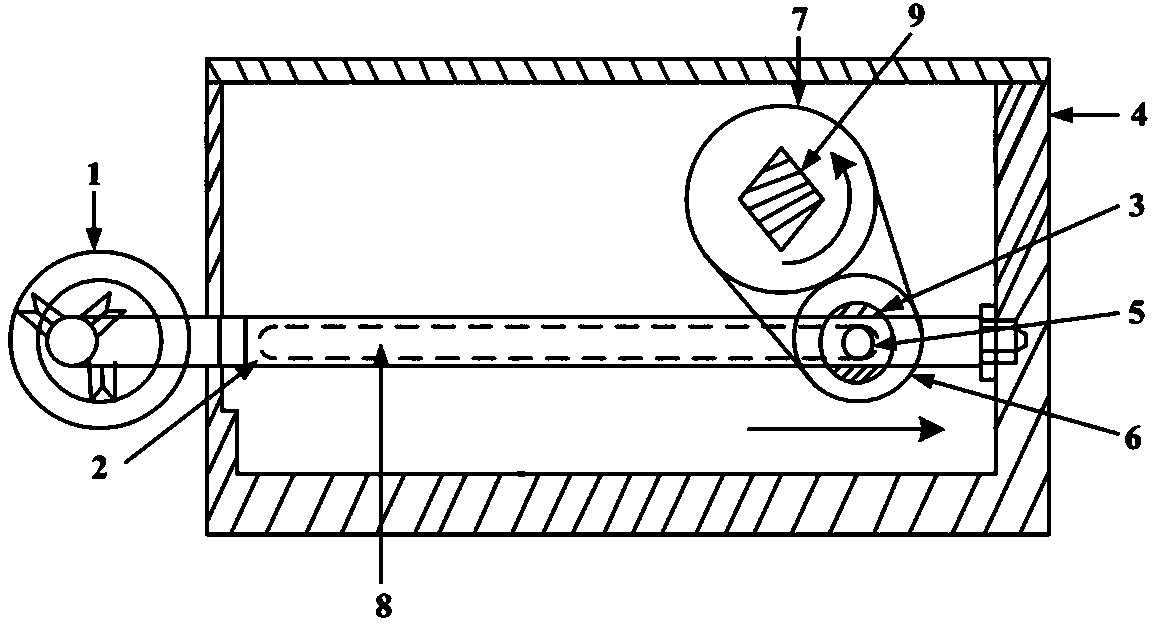

[0043] figure 2 Schematic diagram of the anti-surge butterfly valve structure. Including handle 1, screw shaft 2, first gear plate 3, gear box 4, joint protrusion 5, second gear plate 6, third gear plate 7, sliding groove 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com