Genetic engineering bacteria for producing L-lactic acid from acetic acid, construction method thereof and application thereof

A construction method, gene technology, applied in the field of genetic engineering, fermentation engineering, and biotechnology, can solve the problems of restricting wide application and high market price of L-lactic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

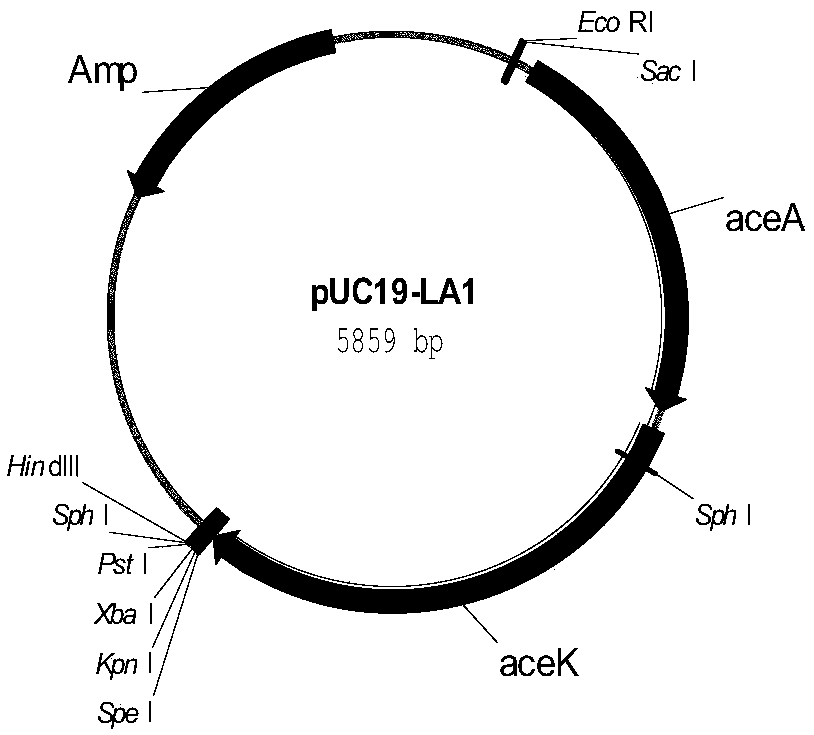

[0146] Example 1. Construction of recombinant bacteria E.coli LA5 (pMCS-LA2+pUC19-LA4)

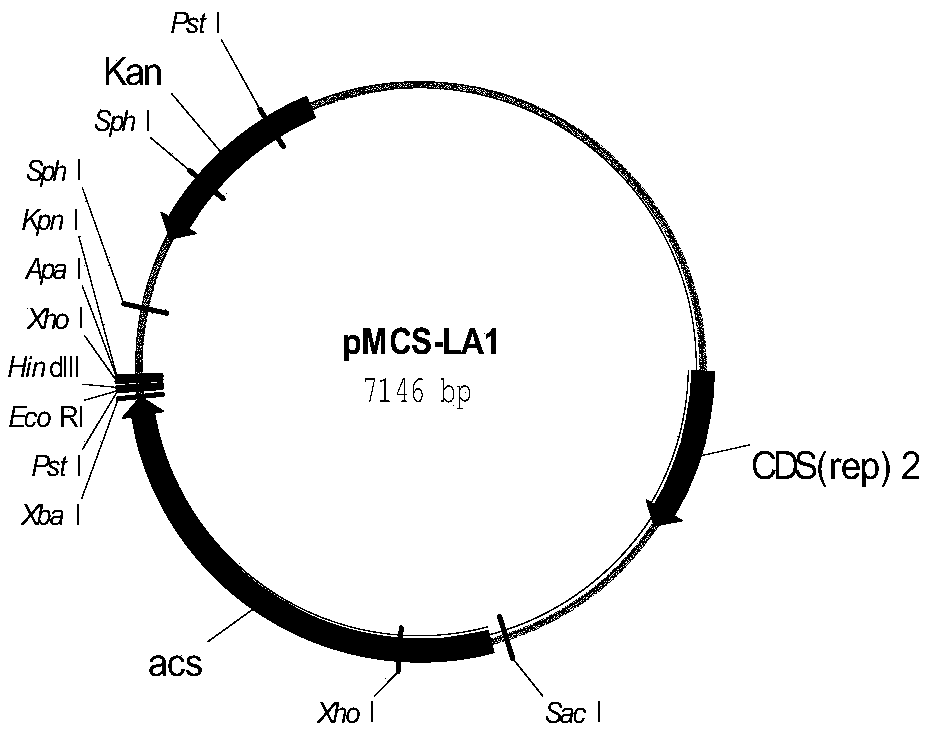

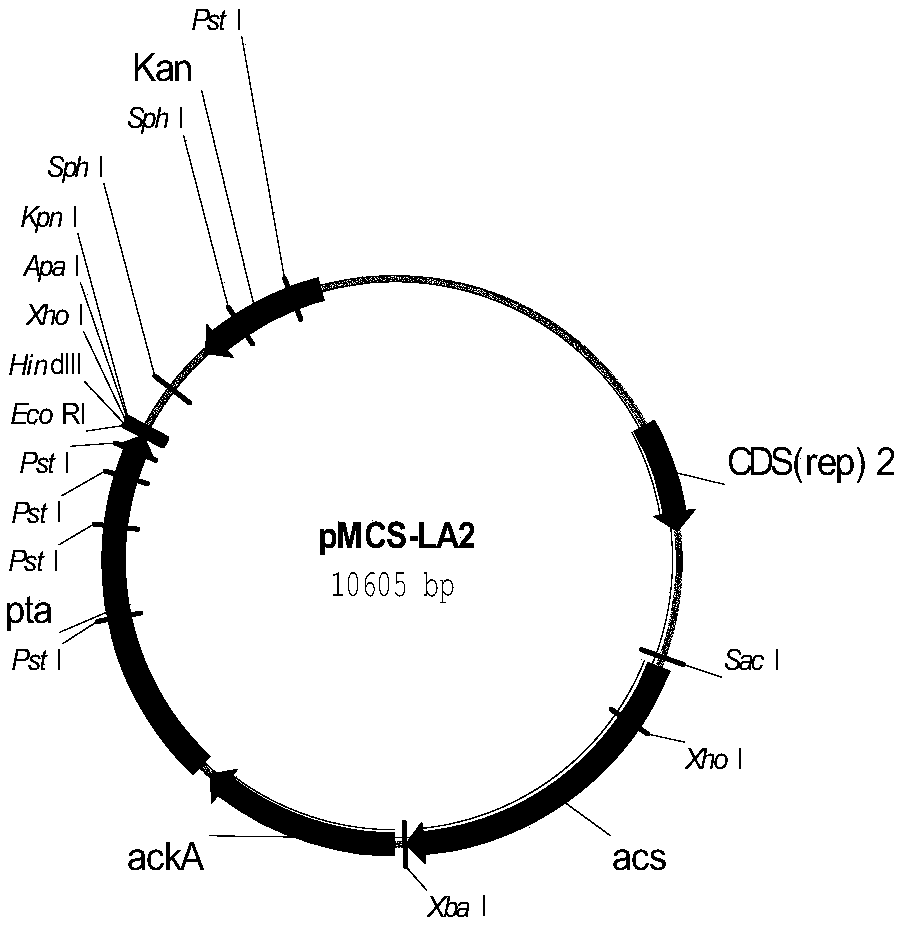

[0147] 1. Construction of recombinant expression vectors pMCS2-LA1 and pMCS2-LA2

[0148] 1. The artificially synthesized DNA shown in Sequence 1 in the sequence list contains the acs expression cassette, the upstream is the SacI site, and the downstream is the XbaI site, wherein the 9th-51st nucleotide is the promoter sequence, and the 70th-2028th nucleotide Nucleotides are acs gene sequences.

[0149] 2. The artificially synthesized DNA shown in Sequence 2 in the sequence list contains ackA and pta expression cassettes, the upstream is the XbaI site, and the downstream is the EcoRI site, wherein the 9th-51st nucleotides are the promoter sequence, and the 70th- Nucleotide 1272 is the ackA gene sequence, and 1347-3491 nucleotides are the pta gene sequence.

[0150]3. Use SacI and XbaI to double digest the DNA sequence synthesized in sequence 1, and recover a DNA fragment with a size of a...

Embodiment 2

[0233] Embodiment 2, the application of recombinant bacteria E.coli LA5 (pMCS-LA2+pUC19-LA4) in the production of L-lactic acid

[0234] 1. Shake flask culture experiment of recombinant bacteria E.coli LA5 (pMCS-LA2+pUC19-LA4)

[0235] 1. Cultivate the E.coli LA5 (pMCS-LA2+pUC19-LA4) prepared in step 7 of Example 1 in LB liquid medium containing ampicillin and kanamycin at 37°C and 200rpm for 16h , as a seed solution.

[0236] 2. Inoculate the seed liquid into the MM liquid medium containing ampicillin and kanamycin according to the inoculation amount of 4% by volume, and the liquid amount in a 250 ml shake flask is 50 ml, and cultivate under the condition of 37 ° C and 100 rpm At 24h, the fermentation broth was collected at 12h and 24h of cultivation, respectively.

[0237] 3. Quantitative detection of L-lactic acid produced by genetically engineered bacteria and acetic acid consumed by high performance liquid chromatography. The specific conditions are as follows:

[023...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com