Production process of biomass particle fuel

A biomass particle and production process technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of cumbersome production process, large resource waste, poor particle quality, etc., and achieve enhanced combustion quality, less resource waste, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

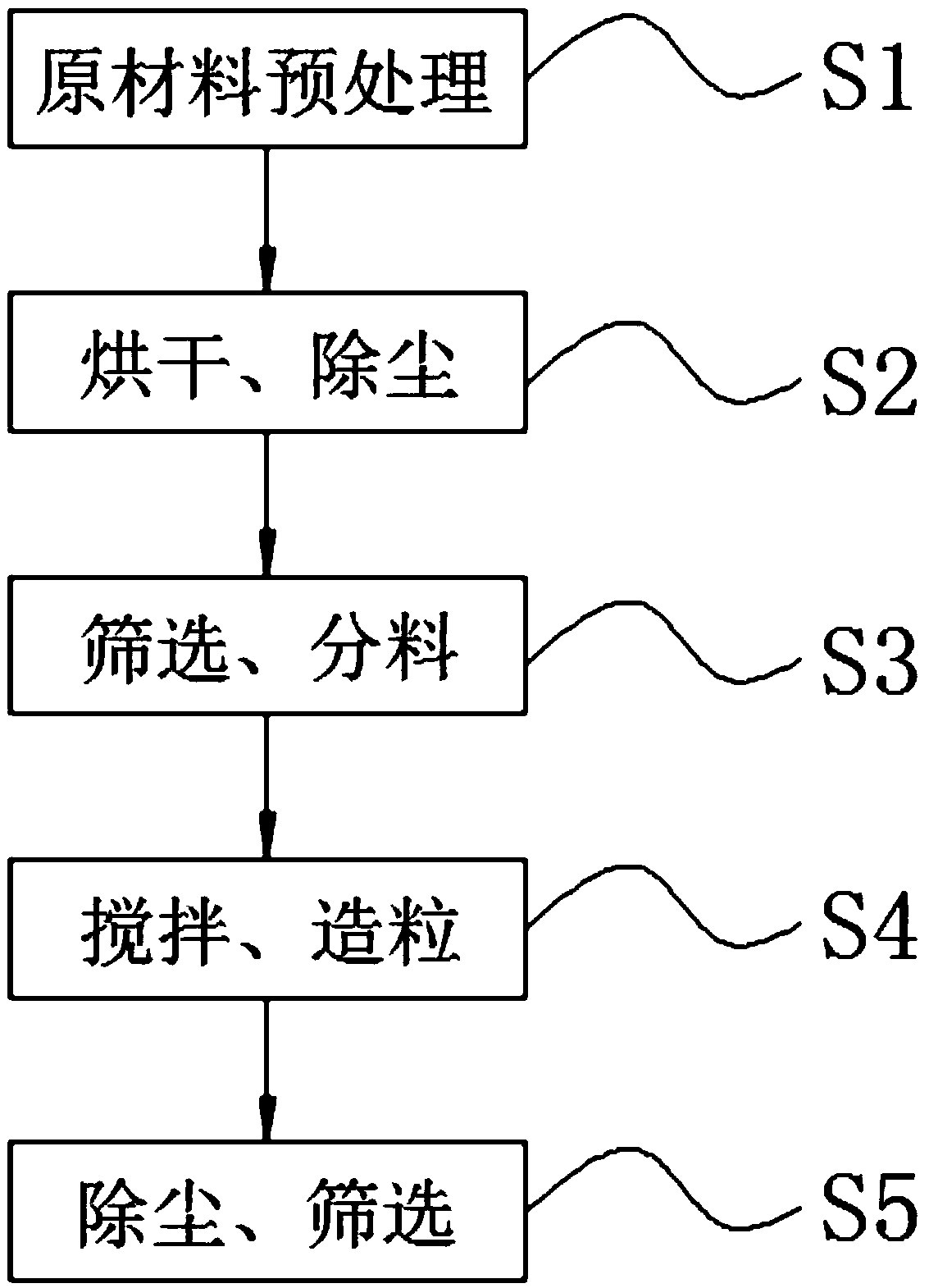

[0028] A production process of biomass pellet fuel, comprising the following steps:

[0029] S1. Raw material pretreatment: first air-dry the material, and then use a pulverizer to crush different types of materials to less than 200mm;

[0030] S2. Drying and dust removal: use a dryer to dry the crushed material of S1 to keep the water content below 15%, and then remove dust from the material after drying to remove powder with a particle size of less than 0.1mm;

[0031] S3. Screening and material separation: use drum sieve to screen and separate the pulverized materials, and then dry and dehumidify the separated materials to obtain materials with different particle sizes;

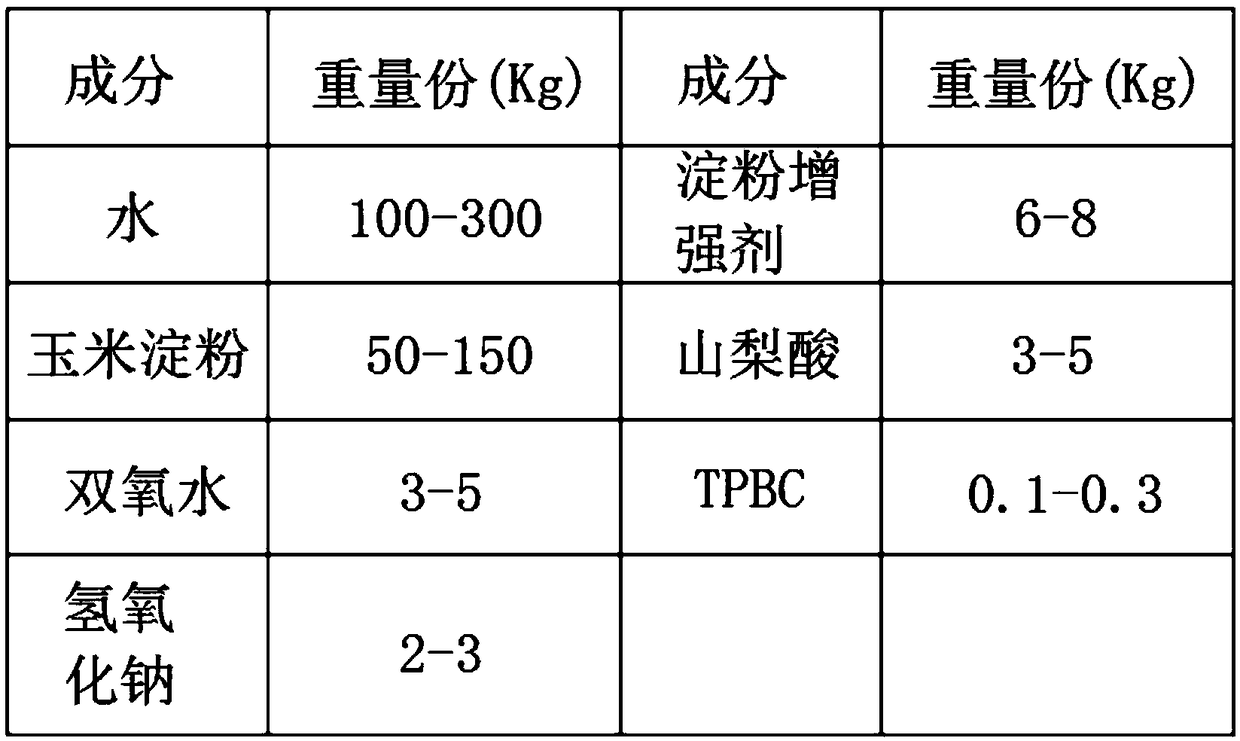

[0032] S4. Stirring and granulation: Put different types of small particle size materials in S3 into the mixer for uniform mixing. The time is controlled within 30 minutes. During this period, add binder to the mixer until the mixing is uniform, and then convey the stirred materials Enter the pelletizing ...

Embodiment 2

[0045] A production process of biomass pellet fuel, comprising the following steps:

[0046] S1. Raw material pretreatment: first air-dry the material, and then use a pulverizer to crush different types of materials to less than 200mm;

[0047] S2. Drying and dust removal: use a dryer to dry the crushed material of S1 to keep the water content below 15%, and then remove dust from the material after drying to remove powder with a particle size of less than 0.1mm;

[0048] S3. Screening and material separation: use drum sieve to screen and separate the pulverized materials, and then dry and dehumidify the separated materials to obtain materials with different particle sizes;

[0049] S4. Stirring and granulation: Put different types of small particle size materials in S3 into the mixer for uniform mixing. The time is controlled within 30 minutes. During this period, add binder to the mixer until the mixing is uniform, and then convey the stirred materials Enter the pelletizing ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com