Acrylic ester solid restickable adhesive and preparation and coating method thereof

A technology of acrylate and coating method, applied in the direction of adhesive, ester copolymer adhesive, adhesive type, etc., can solve the problems of spacer paper coating variation, environmental pollution of solvent-based adhesive, insufficient adhesive force, etc. To achieve the effect of reducing electricity consumption, simple and effective coating method, and enhancing initial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of acrylate solid repositionable adhesive comprises the following steps:

[0030] (1) Mixing: mix the acrylate monomer, unsaturated acid, functional monomer, special monomer, crosslinking agent and initiator uniformly by weight to obtain a mixture;

[0031] (2) The first stage of reaction: heat the mixture obtained in step (1) and maintain it in the temperature range of 80-90°C, and when the mixture becomes viscous, cool down to 50-70°C and keep it warm for 2 hours;

[0032] (3) Second stage reaction: heat the mixture obtained in step (2) to a temperature range of 150-180°C for reaction, stop the reaction when it reaches a fluid state, and the reaction time is 40-45 minutes to obtain a fluid polymer .

[0033] (4) Solidification: Cool the fluid polymer obtained in step (3) to below minus 70° C., the fluid polymer solidifies into a solid state, and obtains an acrylate solid repositionable adhesive.

[0034]It completely solves the problem of defo...

Embodiment 1

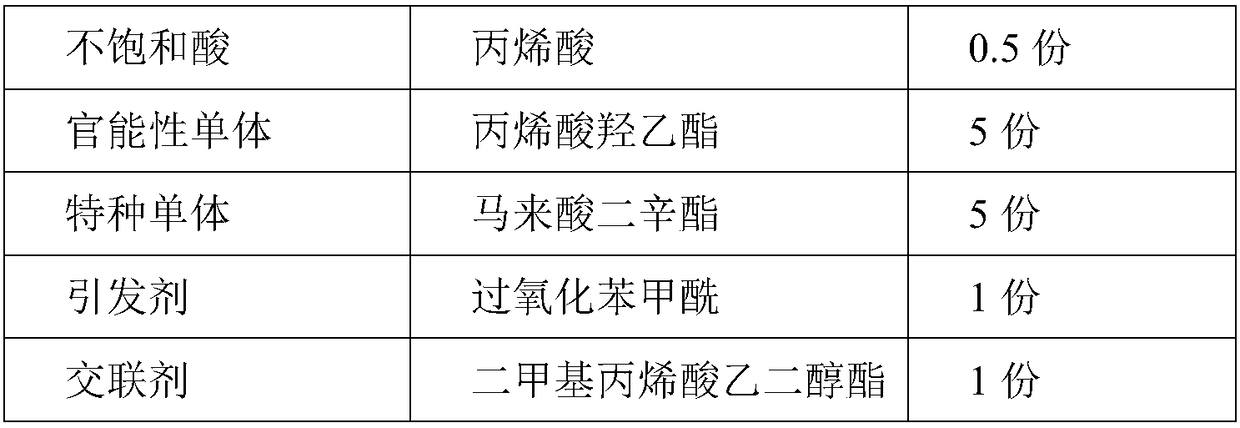

[0050] A kind of acrylate solid repositionable adhesive, its raw material composition is as shown in table 1:

[0051] The raw material composition of the acrylate solid repositionable adhesive of table 1 embodiment 1

[0052]

[0053]

[0054] The preparation method of the above-mentioned acrylate solid repositionable adhesive comprises the following steps:

[0055] (1) Mixing: mix the acrylate monomer, unsaturated acid, functional monomer, special monomer, crosslinking agent and initiator uniformly by weight to obtain a mixture;

[0056] (2) The first stage of reaction: heat the mixture obtained in step (1) and maintain it in the temperature range of 80-90°C, and when the mixture becomes viscous, cool down to 50-70°C and keep it warm for 2 hours;

[0057] (3) Second stage reaction: heat the mixture obtained in step (2) to a temperature range of 150-180°C for reaction, stop the reaction when it reaches a fluid state, and the reaction time is 40-45 minutes to obtain a f...

Embodiment 2

[0060] A kind of acrylate solid repositionable adhesive, its raw material composition is as shown in table 2:

[0061] The raw material composition of the acrylate solid repositionable adhesive of table 2 embodiment 2

[0062]

[0063] The preparation method of the above-mentioned acrylate solid repositionable adhesive comprises the following steps:

[0064] (1) Mixing: mix the acrylate monomer, unsaturated acid, functional monomer, special monomer, crosslinking agent and initiator uniformly by weight to obtain a mixture;

[0065] (2) The first stage of reaction: heat the mixture obtained in step (1) and maintain it in the temperature range of 80-90°C, and when the mixture becomes viscous, cool down to 50-70°C and keep it warm for 2 hours;

[0066] (3) Second stage reaction: heat the mixture obtained in step (2) to a temperature range of 150-180°C for reaction, stop the reaction when it reaches a fluid state, and the reaction time is 40-45 minutes to obtain a fluid polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com