Rubbish transfer station rubbish treatment system and rubbish decrement method adopting same

A technology of waste disposal system and transfer station, applied in the field of waste reduction and waste disposal system of waste transfer station, can solve the problems of secondary pollution, accumulation of leachate, slow self-flow rate of leachate, etc., to save energy and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

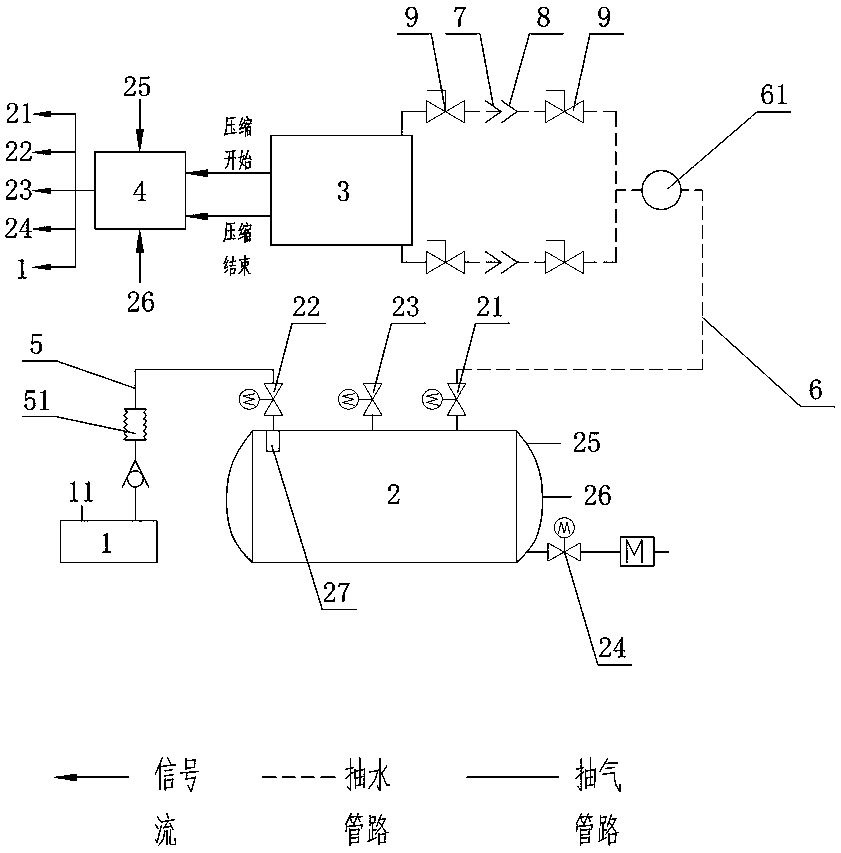

[0029] The garbage transfer station garbage treatment system of the present embodiment, such as figure 1 As shown, it includes a vacuum pump 1 installed in the garbage transfer station, a leachate collection tank 2, a garbage compressor with a compression head (not shown in the figure) and a garbage compression box 3 that can be transported in and out of the garbage transfer station by vehicles. A control center 4 is also provided in the refuse transfer station. The exhaust port of the vacuum pump 1 is provided with a deodorizing device 11 .

[0030] A suction pipeline 5 is connected between one end of the leachate collection tank 2 and the vacuum pump 1 , and a suction pipeline 6 is connected with the other end of the leachate collection tank 2 . A check valve is installed on the exhaust pipeline 5, which can prevent the reverse of the vacuum pump 1 caused by the recoil of the airflow when the pump is stopped. A compensator 51 is installed on the exhaust pipeline 5, which ca...

Embodiment 2

[0046] The waste treatment system of the waste transfer station in this embodiment and the waste reduction method using the system are improvements on the basis of the first embodiment, and the difference from the first embodiment is that:

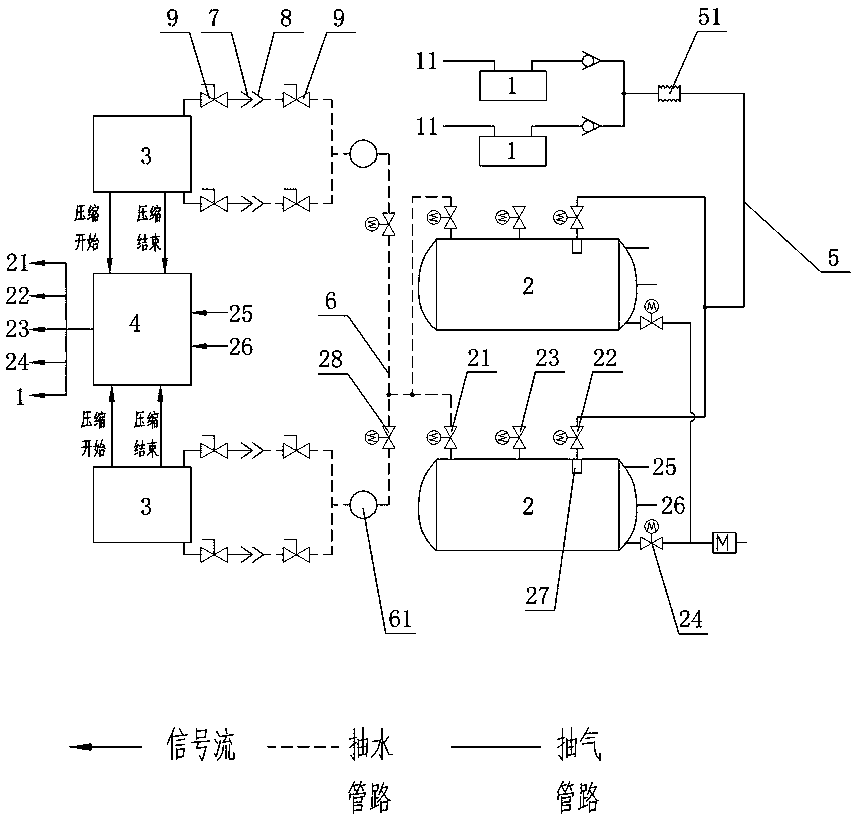

[0047] The garbage transfer station is generally equipped with one or two sets of independent work (such as figure 2 shown) or three sets of independent compressors, which are respectively connected to independent garbage compression boxes 3, each garbage compression box is independently provided with a pumping pipeline 6 and a pumping valve 28 (which can be electronically controlled), and each garbage compression box 3 The pumping pipelines 6 are connected in parallel.

[0048] Each garbage transfer station garbage treatment system includes one or more pumping pipelines 6, drainage pipelines and leachate collection tanks 2 connected in parallel with the suction pipelines 5, and the pumping pipelines 6 of each tank are connected in parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com