Rubber double-density double-injection product intra-mold foaming and sulfuration molding system and process

A technology of vulcanization molding and double density, which is applied in the field of rubber product technology, can solve the problems of cumbersome process, large equipment investment and high equipment maintenance cost, and achieve the effect of large equipment investment, high equipment maintenance cost and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

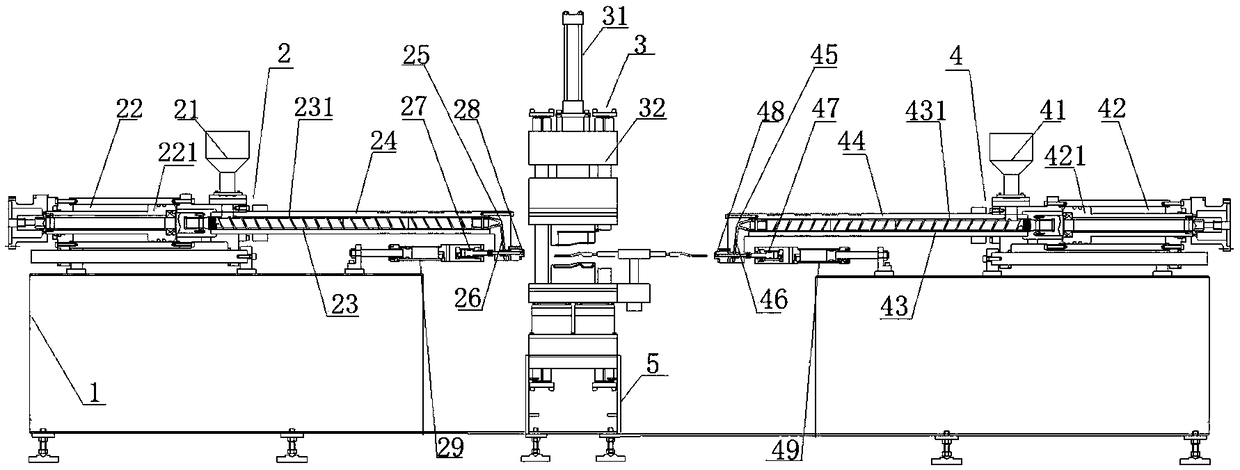

[0043] The in-mold foaming vulcanization molding system of the rubber double density double injection product of the present embodiment, such as figure 1 As shown, it includes injection molding vulcanization table 5 and two injection machine bases 1 symmetrically arranged on both sides thereof, on which compression molding vulcanization device 3 is fixed; on the two injection machine bases 1 Rubber material injection devices are respectively fixed, and two rubber material injection devices are arranged opposite to each other, which are respectively a high-density rubber material injection device 2 and a low-density rubber material injection device 4; The high-density rubber material injection device 2 and the low-density rubber material injection device 4 respectively inject two plasticized rubber materials with different densities corresponding to different mold cores into the mold of the compression molding vulcanization device 3 , the compression molding vulcanization devic...

Embodiment 2

[0046] The basic structure of the in-mold foaming and vulcanization molding system for rubber double-density double-injection products in this embodiment is the same as in Embodiment 1, and the improvement is that the two rubber material injection devices are high-density rubber material injection device 2 and low-density rubber material injection device respectively. The injection device 4; the high-density rubber material injection device 2 includes a high-density rubber material feeding hopper 21, a high-density rubber material injection cylinder 22, a high-density rubber material plasticizing injection screw barrel 23, a high-density rubber material plasticizing heater 24, a high-density rubber material plasticizing Density rubber injection nozzle control cylinder 27, high-density rubber injection head 28 and high-density rubber injection seat moving cylinder 29; the high-density rubber feeding hopper 21 communicates with the beginning of high-density rubber plasticizing inj...

Embodiment 3

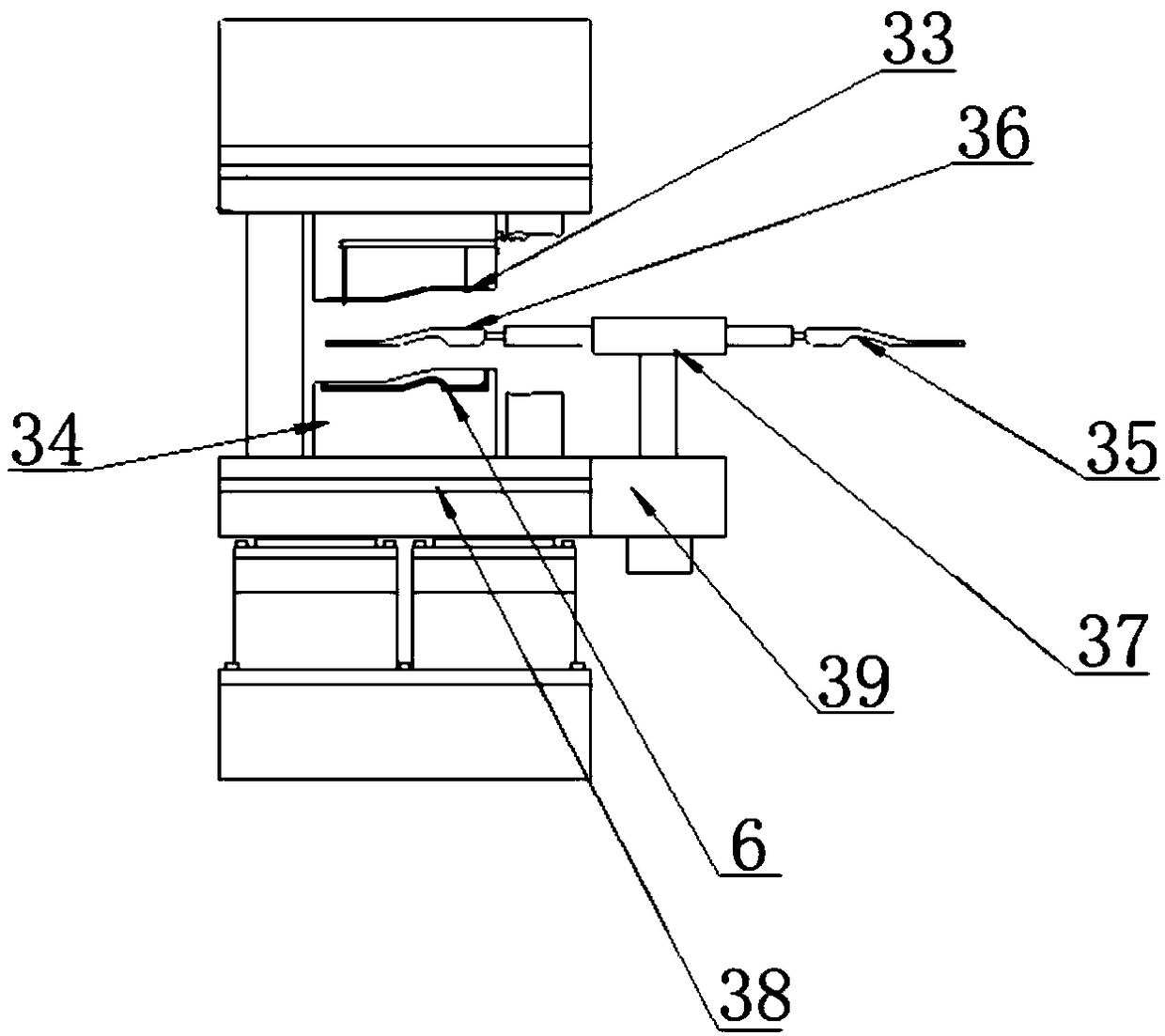

[0048] The in-mold foaming and vulcanization molding system for rubber double-density double-injection products of this embodiment has the same basic structure as that of Embodiment 2, and the improvements are as follows: figure 1 , 2 As shown, the die vulcanization device 3 comprises a clamping oil cylinder 31, an upper half mold 33, a lower half mold 34, a mold inner core one 35, a mold inner core two 36 and a mold core rotating cylinder 39; the lower half mold 34 is fixed on On the press molding vulcanization table 5, an upper half mold 33 is arranged directly above the lower half mold 34, and the upper half mold 33 is detachably connected with the mold clamping oil cylinder 31; the mold clamping oil cylinder 31 is fixed by a fixing frame; Mold inner core 1 35 and mold inner core 2 36 have the same shape and different specifications, and the tail ends of the two are opposite, and both are detachably fixed with the mold core conversion bracket 37. The mold core conversion br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com