Multi-station continuous stamping automatic assembly line mechanism

A multi-station, automatic technology, applied in wood stamping, mechanical equipment, wood compression, etc., can solve the problems of non-recycling, low efficiency, and low utilization rate, and achieve the goal of improving uniformity, improving dust removal effect, and reducing wind loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

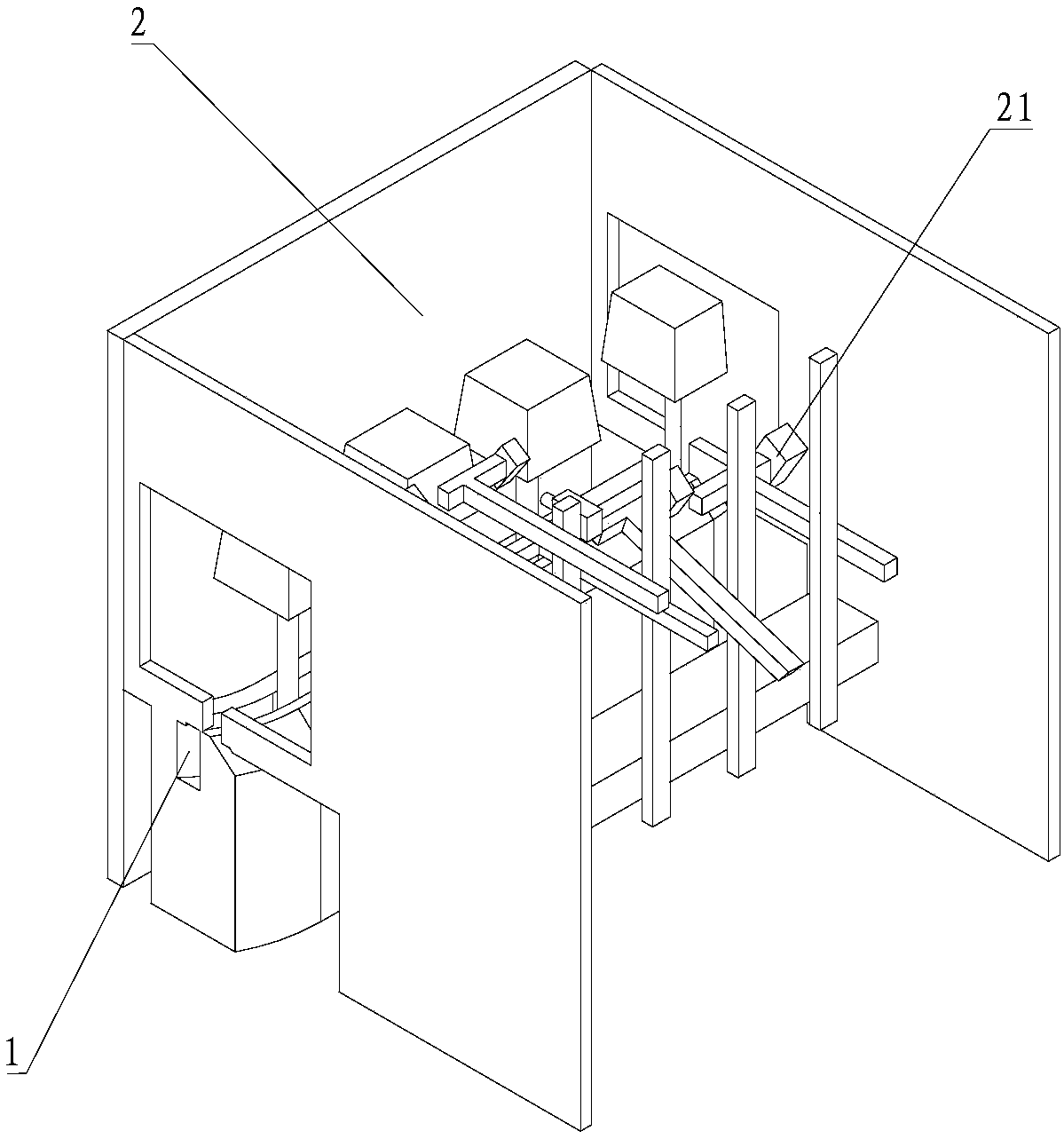

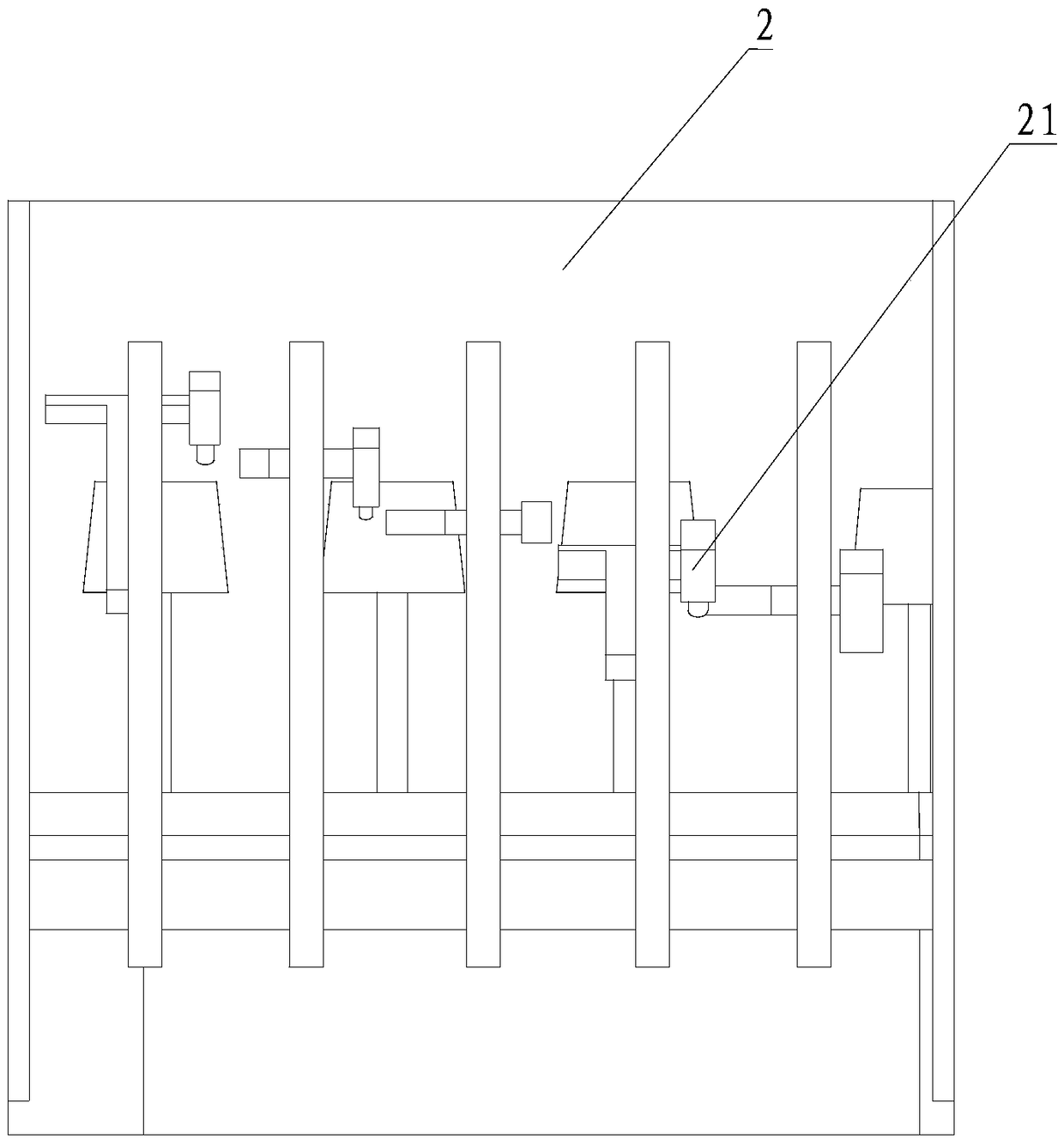

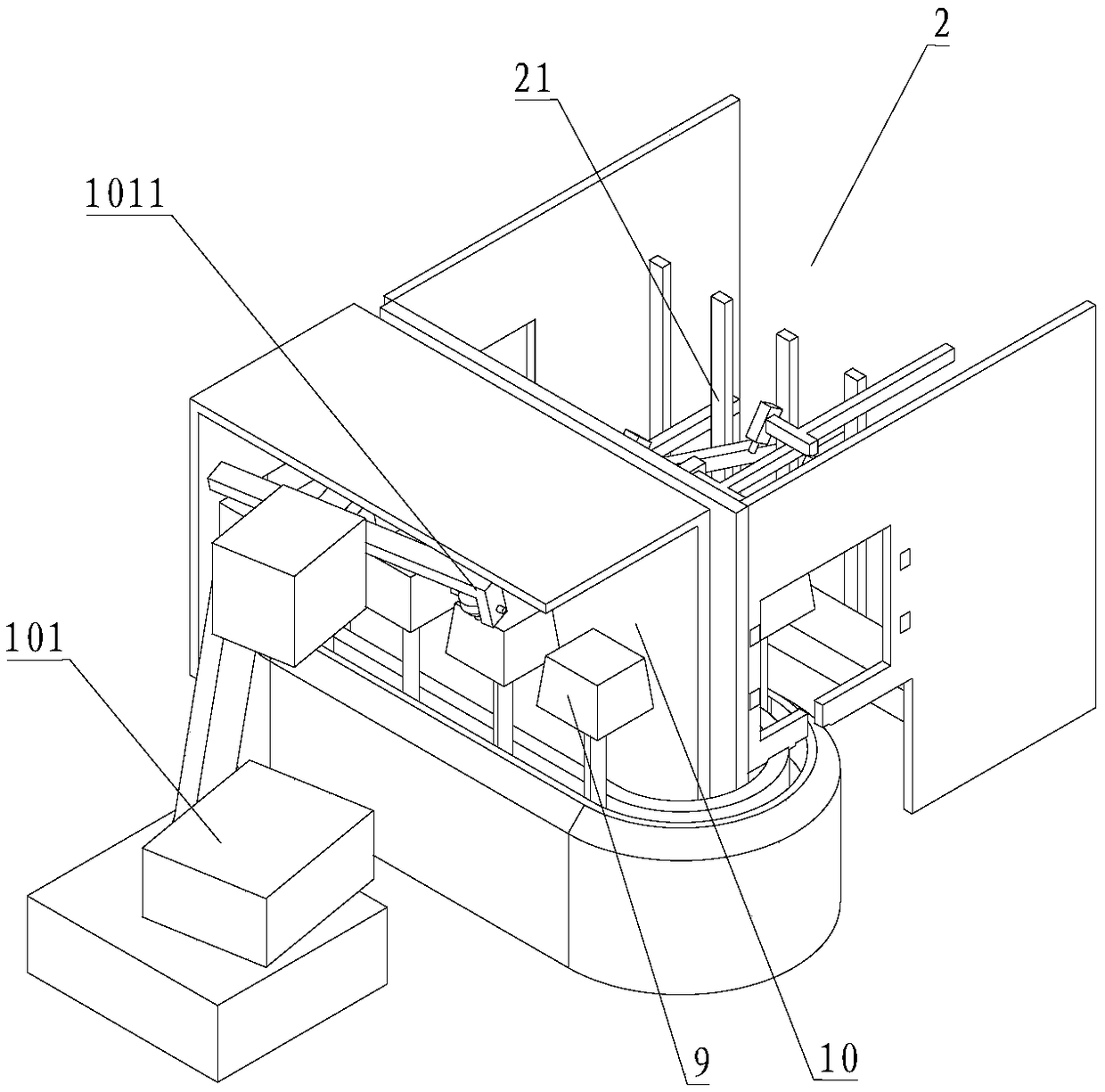

[0050] Please refer to Figure 1 to Figure 6 Shown, embodiment one of the present invention is:

[0051] A multi-station continuous stamping automatic flow mechanism provided by the present invention includes a horizontal circularly distributed conveying chain 1 and a stamping chamber 2 erected on the conveying chain, the conveying chain 1 runs along one direction, and the conveying chain 1 A horizontally rotating support frame 3 is provided, and the stamping chamber 2 is provided with a stamping gun 21 positioned on one side of the conveyor chain and facing the bamboo product 9 to be sprayed on the support frame 3, and a plurality of stamping guns 21 along the The one direction is distributed sequentially and the horizontal heights of the plurality of punching guns 21 gradually decrease along the one direction; the air outlet direction of the punching guns 21 is perpendicular to the surface of the bamboo product to be sprayed. That is to say, the muzzle inclinations of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com