Magnetorheological fluid grinding and polishing method controlled by alternating electromagnetic field

A magneto-rheological fluid and alternating magnetic field technology, which is applied in grinding/polishing equipment, surface polishing machine tools, manufacturing tools, etc., can solve problems such as large inertia, inconvenient magnetic field, and reduced grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

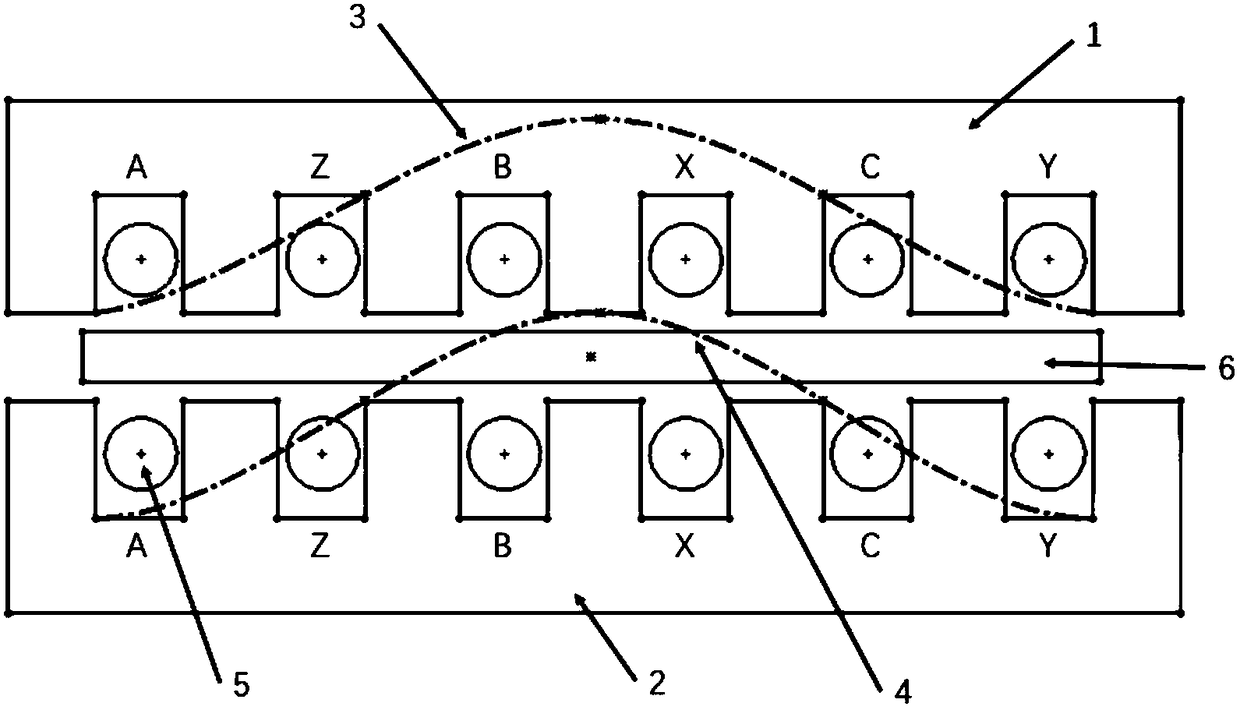

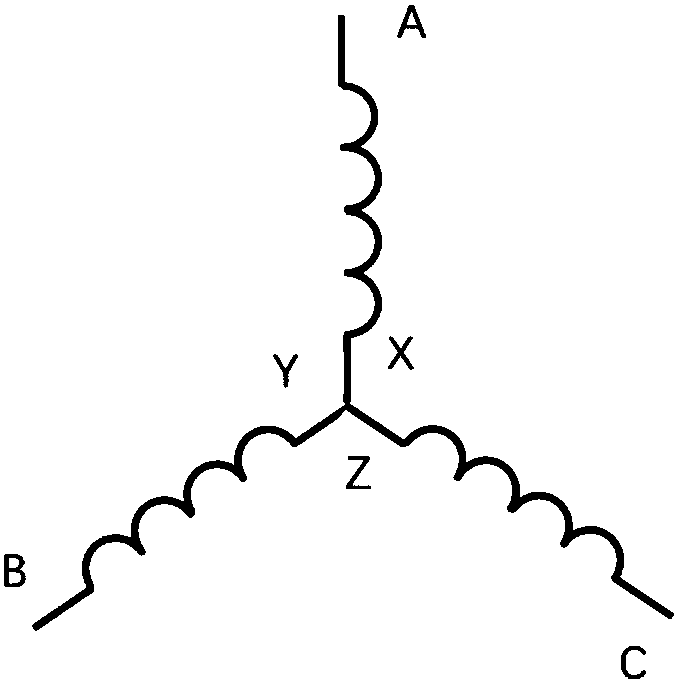

[0014] The invention is a magneto-rheological fluid grinding and polishing method based on the action of a moving magnetic field. The basic principle diagram is as follows figure 1 As shown: 1, 2 are the upper and lower electromagnetic control panels, and the middle is filled with magnetorheological fluid; 3, 4 are schematic diagrams of the distribution of the magnetic field strength formed by the electromagnetic control panel; 5 is the winding; 6 is the workpiece (non-magnetic magnetic permeable material , such as Si, SiC, glass and ceramic materials, etc.). The upper and lower electromagnetic control panels are made of silicon steel sheets laminated. There is a wire slot on the silicon steel sheet, and a winding 5 is wound in the slot. The winding is connected to each terminal of the winding according to the principle of an AC linear motor....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com