Power-split multi-stage continuously variable transmission device and method for changing stages

A technology of transmission and stepless speed change, which is applied in the direction of transmission, transmission parts, gear transmission, etc., to achieve the effects of shifting control and loose operating conditions, avoiding power interruption, and avoiding the effect of shifting cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

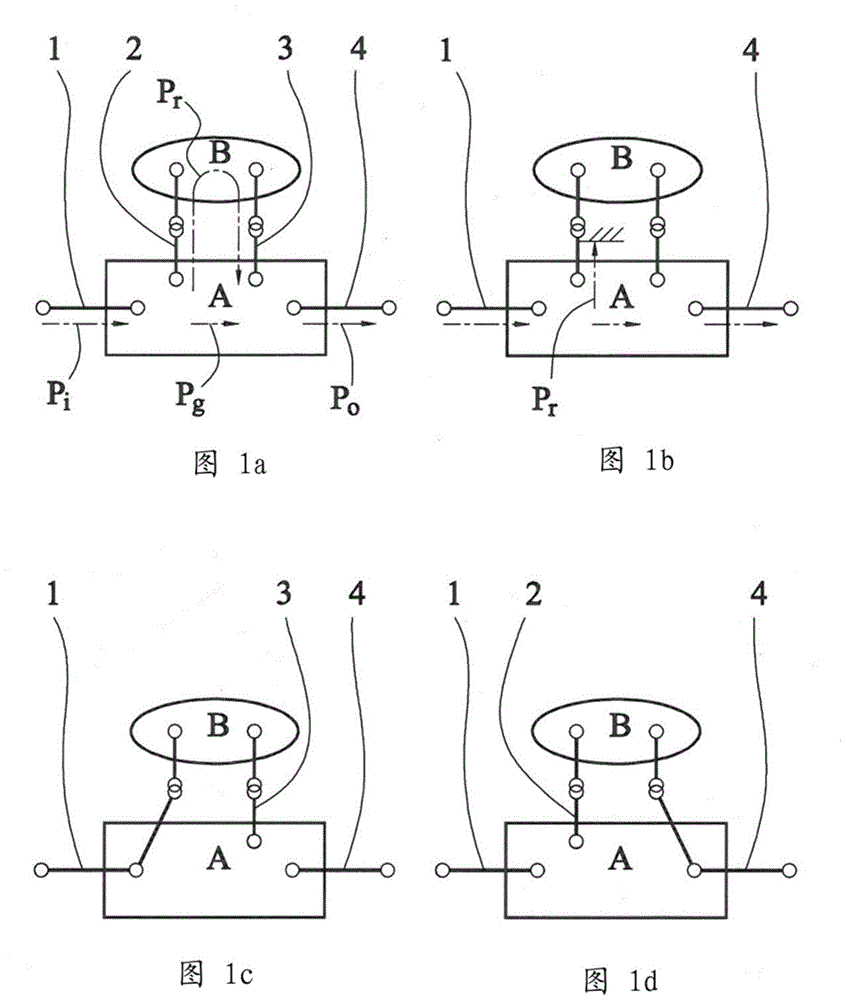

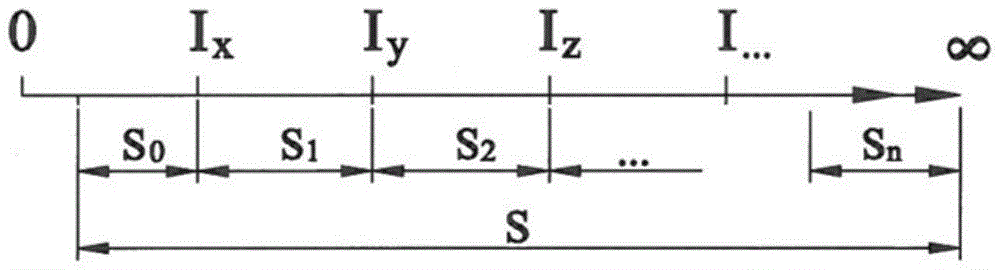

[0031] The existing power split transmission device is shown in Figure 1a As shown, it has a driving part 1 and a driven part 4; it includes a set of continuously variable transmission B used as a governor, and a multi-speed gear train A; in the stepless speed regulation state of the device, the multi-speed gear train A The degrees of freedom are 2.

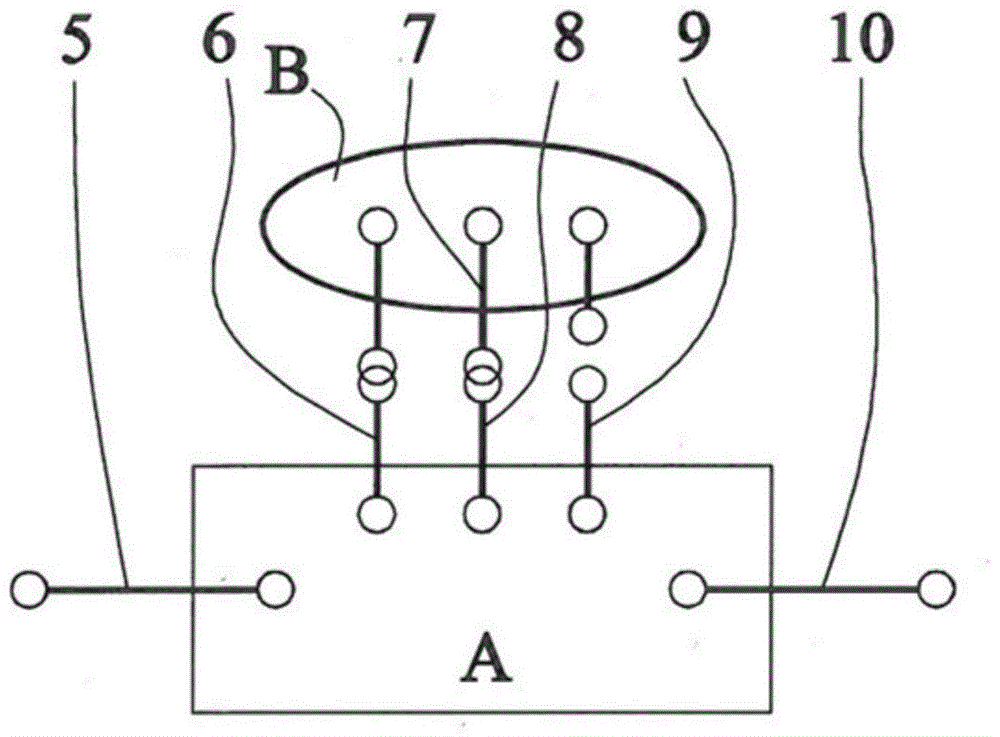

[0032] The speed governor B has two transmission parts that can be connected with the multi-degree wheel train A, called speed regulating parts, and its speed ratio can be adjusted steplessly. The multi-degree gear train A has at least two transmission parts 2 and 3 that move independently of each other in the gear train, which are called adjusted parts. The speed regulating parts are respectively connected with one regulated part.

[0033] In the multi-degree gear train A, the adjusted parts that can be connected with the speed regulating parts respectively are called the available adjusted parts; including the adjusted parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com