Food sucker

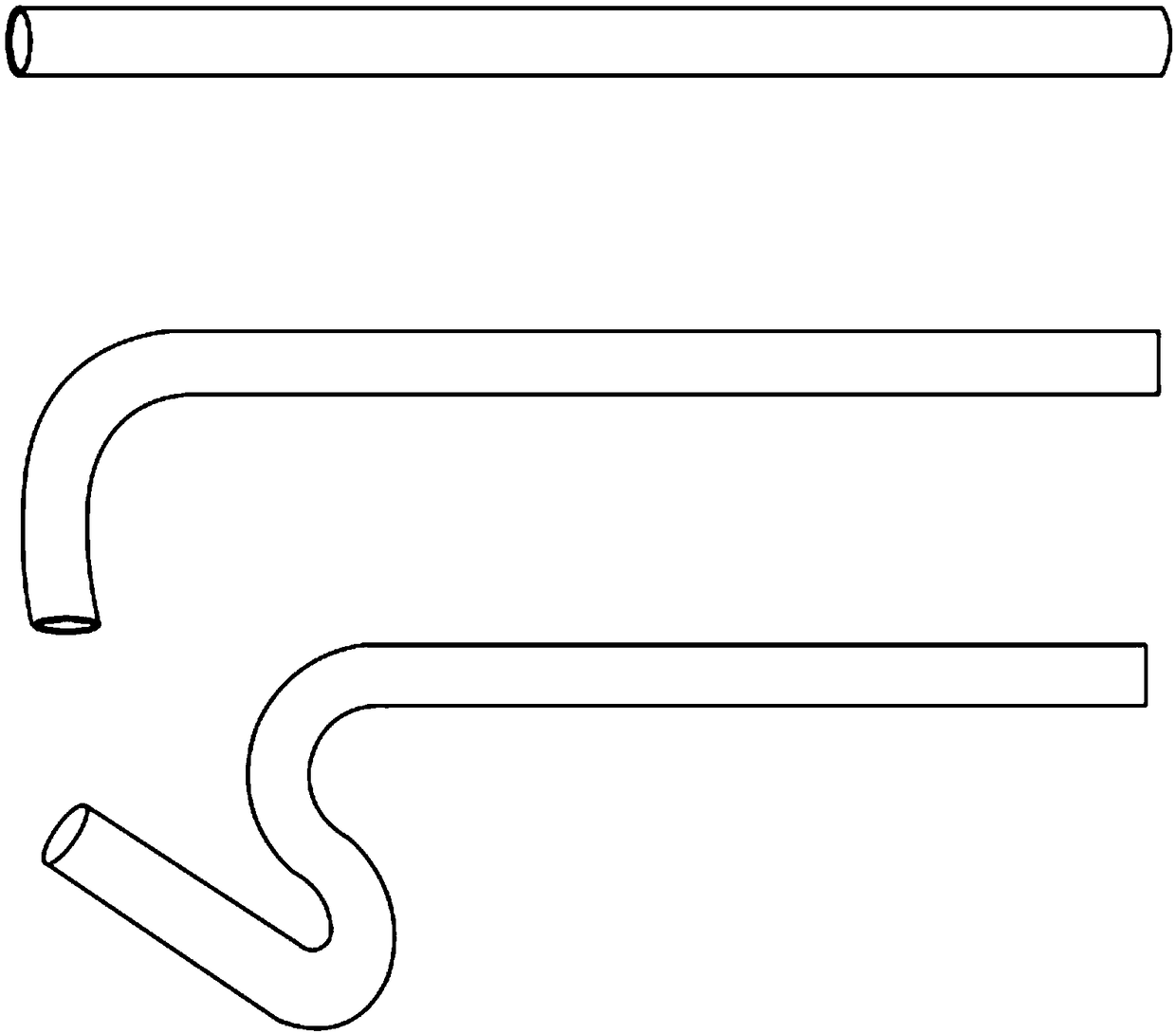

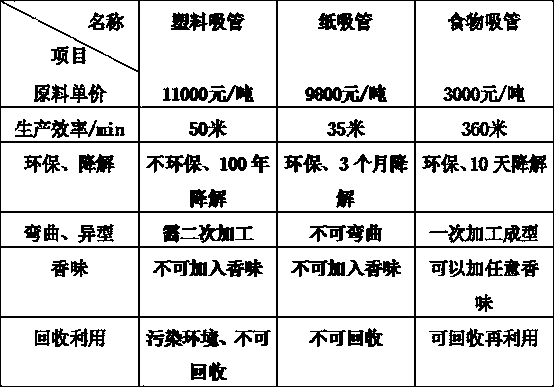

A straw and food technology, applied in food science, table utensils, home utensils, etc., can solve the problems of inability to produce curved and special-shaped straws, harmful odor and gas, and high production cost of straws, and achieve simple and fast mold replacement and high recycling , rapid natural degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 80% flour as the main raw material, and add a little starch, guar gum and stabilizer to it, and stir it to make it mix evenly to obtain wet powder, and send the wet powder into the extruder, And control the temperature and pressure in the extruder to increase, so that the wet powder is half-cooked, fully cooked or puffed, and then extruded through the forming die hole at the outlet end of the cylinder liner, and the wet tube extruded by the extruder enters the straight die through the guide table , bending die or special-shaped mold, and bend the wet pipe into a specified shape according to the shape of the straight die, bending die or special-shaped mold, cut the bent wet pipe, make it fall into the dryer, and use infrared rays to make the cut The temperature of the wet tube is raised to make it dry, and at the same time, it is sterilized by ultraviolet rays. The straw after sterilization and drying automatically falls into the cooling device, and the finished opa...

Embodiment 2

[0034] Weigh 80% flour and starch as the main raw materials, and add guar gum and stabilizer to it, and stir it to make it mix evenly to obtain wet powder, send the wet powder into the extruder, and control The temperature and pressure in the extruder rise to make the wet powder semi-cooked, fully cooked or puffed, and then extruded through the forming die hole at the outlet end of the cylinder liner, and the wet tube extruded by the extruder enters the straight die, curved tube through the guide table. mold or special-shaped mold, and bend the wet pipe into a specified shape according to the shape of the straight mold, bending mold or special-shaped mold, cut the bent wet pipe, make it fall into the dryer, and use infrared rays to make the cut pipe The temperature of the wet tube is raised to make it dry, and at the same time, it is sterilized by ultraviolet rays. The sterilized and dried straw automatically falls into the cooling device, and the translucent finished straw is ...

Embodiment 3

[0036] Weigh 80% starch as the main raw material, add guar gum and stabilizer to it, and stir it to make it evenly mixed to obtain wet powder, send the wet powder into the extruder, and control the extrusion The temperature and pressure inside the machine rise to make the wet powder half-cooked, fully-cooked or puffed, and then extruded through the forming die hole at the outlet end of the cylinder liner, and the wet tube extruded by the extruder passes through the guide table and enters the straight die, bending die or According to the shape of the straight die, bending die or special-shaped die, the wet pipe is bent into a specified shape, the bent wet pipe is cut off, and it falls into the dryer, and the cut wet pipe is cut by infrared rays. The temperature rises to make it dry, and at the same time, ultraviolet rays are used to sterilize it. The sterilized and dried straws automatically fall into the cooling device, and the transparent finished straws are obtained after bei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com