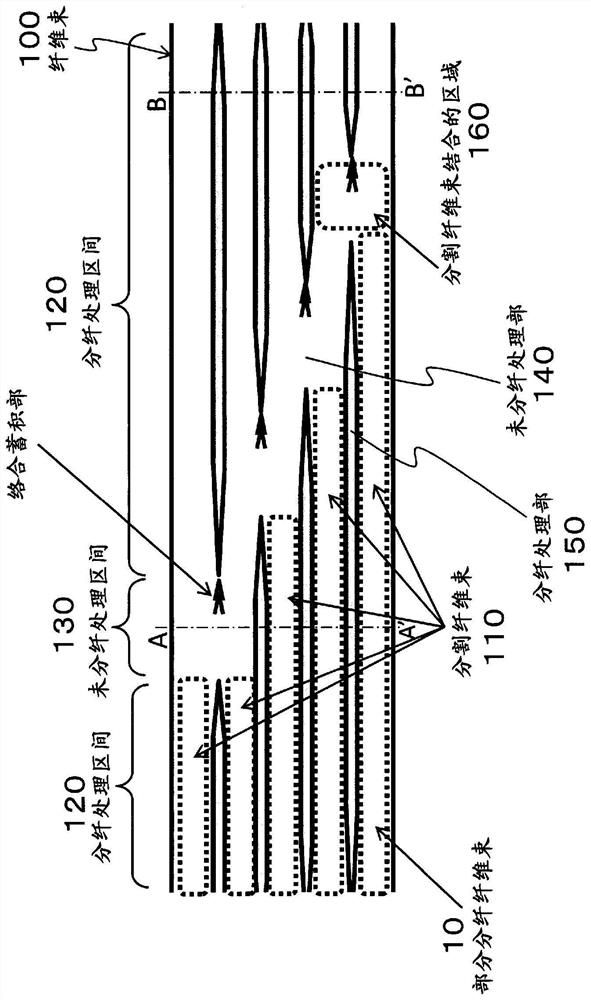

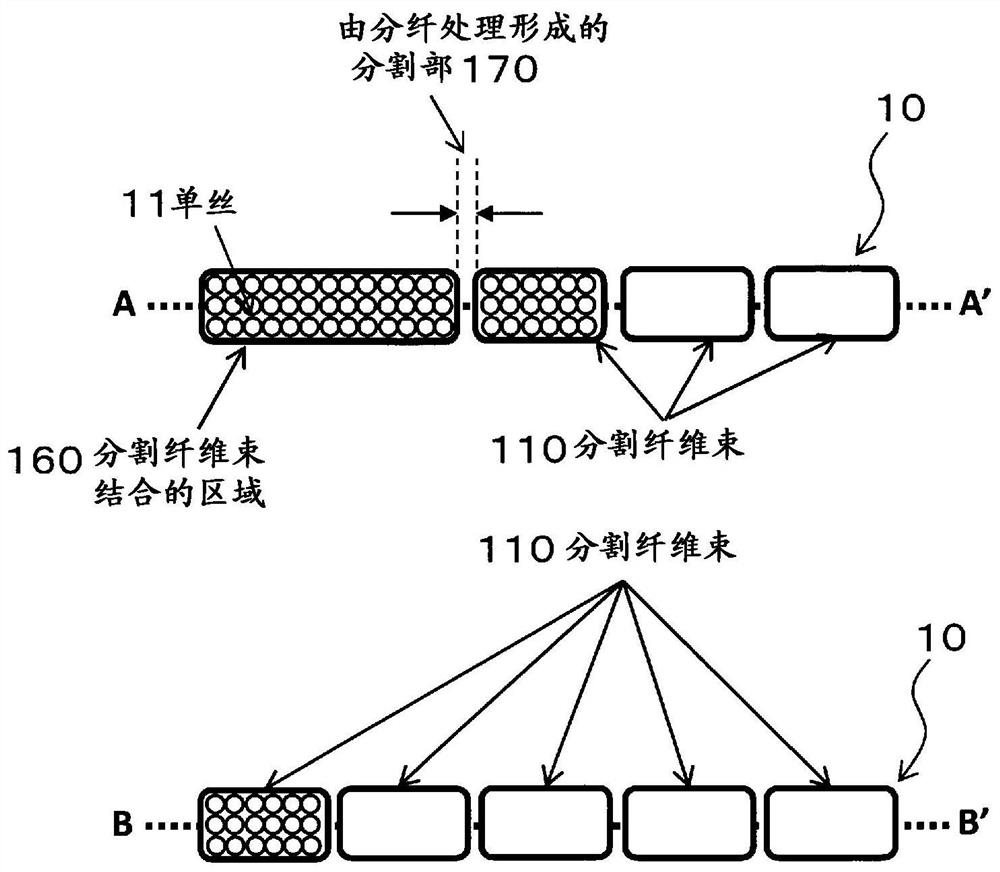

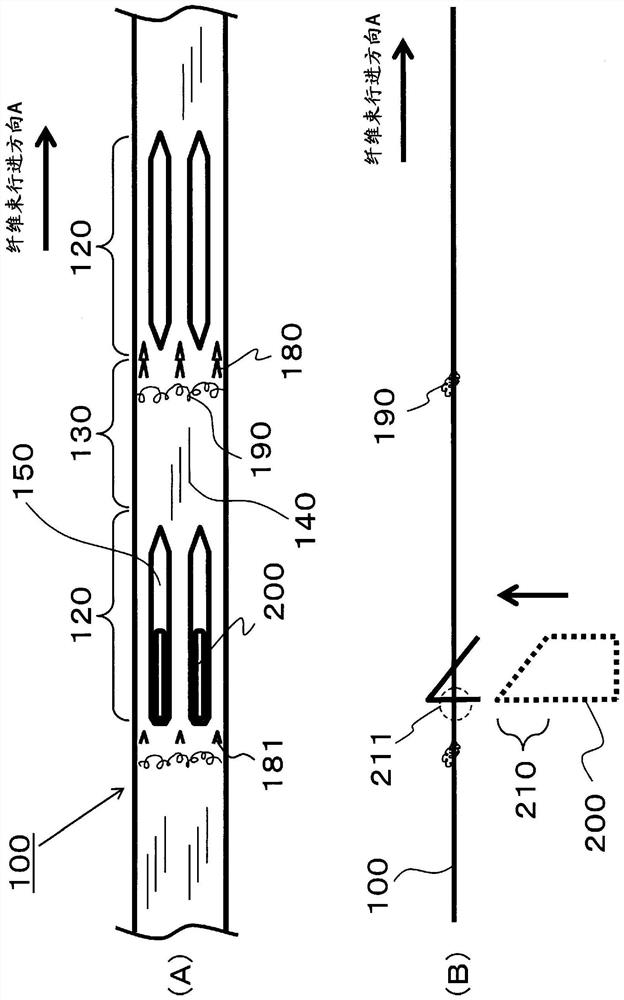

Partially divided fiber bundle and its manufacturing method

A manufacturing method and a technology of fiber bundles, which are applied in the field of partially split fiber bundles and their manufacture, can solve the problems of being unable to control the length of the split treatment section and the non-fiber treatment section, and difficult to obtain the split fiber bundles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0131] Next, examples and comparative examples of the present invention will be described. It should be noted that the present invention is not limited in any way by the examples and comparative examples.

[0132] [raw materials to use]

[0133] Fiber bundle [A-1]:

[0134] A continuous carbon fiber bundle (manufactured by ZOLTEK, "PANEX (registered trademark) 35") with a fiber diameter of 7.2 μm, a tensile modulus of elasticity of 240 GPa, and a filament number of 50,000 was used.

[0135] Base resin [M-1]:

[0136] The resin compound obtained in the following manner was used: 100 parts by weight of vinyl ester resin (manufactured by Dow Chemical Co., Ltd., "Derakane (registered trademark) 790"), tert-butyl peroxybenzoate (NOF Co., Ltd., "Perbutyl (registered trademark) Z") 1 part by weight, magnesium oxide (manufactured by Kyowa Chemical Industry Co., Ltd., MgO#40) 4 parts by weight as a thickener, stearin as an internal mold release agent 2 parts by weight of zinc acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com