A kind of preparation method of low-temperature lithium iron phosphate power battery cathode slurry

A technology of lithium iron phosphate and positive electrode slurry, which is applied in the direction of battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the difficulties in the production process of lithium iron phosphate positive pole pieces, battery performance attenuation, organic Oxidative decomposition of electrolyte solution and other problems to achieve the effect of overcoming the problem of difficult bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

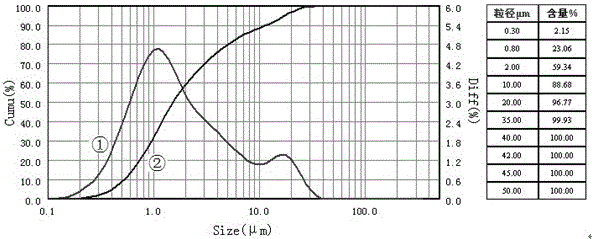

Embodiment 1

[0027] Positive electrode formula: electroactive material lithium iron phosphate, conductive agent is conductive carbon black Super-P and conductive graphite KS-6, binder is LA132 water-based binder, dispersion medium is deionized water, and various substances in the slurry The parts by weight are: lithium iron phosphate: Super-P: KS-6: LA132: water is 90:3:3:4:100.

[0028] Preparation of positive electrode slurry: first add LA132 binder, water and conductive agent to High shear dispersing emulsifier Medium emulsification and dispersion for 1.5 hours, and then gradually adding lithium iron phosphate powder for emulsification and dispersion for 3.5 hours, and finally a small amount of water is used to adjust the viscosity of the positive electrode slurry to the range of 4500 mPas.

[0029] Negative electrode formulation: the negative electrode active material is artificial graphite, the conductive agent is conductive carbon black Super-P, the binder is LA132 water-based binder, the...

Embodiment 2

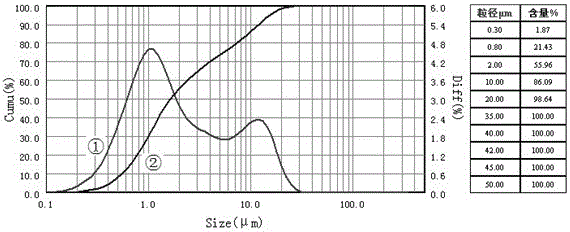

[0032] Example 2 (comparative example)

[0033] Positive electrode formula: electroactive material lithium iron phosphate, conductive agent is conductive carbon black Super-P and conductive graphite KS-6, binder is LA132 water-based binder, dispersion medium is deionized water, and various substances in the slurry The parts by weight are: lithium iron phosphate: Super-P: KS-6: LA132: water is 90:3:3:4:100.

[0034] Preparation of positive electrode slurry: first add LA132 binder, water and conductive agent to High speed mixer Disperse in the medium for 1.5 hours, and then gradually add lithium iron phosphate powder for dispersion for 3.5 hours, and finally adjust the viscosity of the positive electrode slurry to the range of 4500 mPas with a small amount of water.

[0035] Negative electrode formulation: the negative electrode active material is artificial graphite, the conductive agent is conductive carbon black Super-P, the binder is LA132 water-based binder, the dispersion medium...

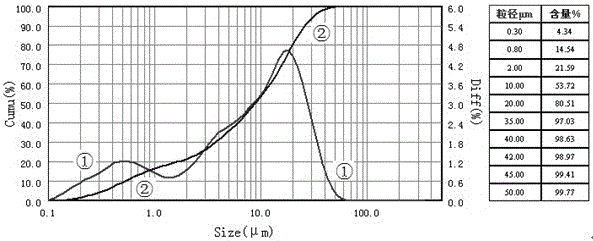

Embodiment 3

[0040] The lithium iron phosphate batteries prepared in Example 1 and Example 2 were tested for low-temperature discharge performance according to the national QC / T743-2006 "Lithium Ion Battery for Electric Vehicles" standard method. The lithium iron phosphate battery prepared by the high-shear dispersing emulsifier has a discharge capacity of 83.4% of the rated capacity at -20°C, and a discharge capacity of 50.9% of the rated capacity at -40°C. The lithium iron phosphate battery prepared with a high-speed mixer has a discharge capacity of 62.5% of the rated capacity at -20°C, and basically cannot discharge at -40°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com