Melt treating apparatus and melt treating method

A processing device and melt technology, applied in the direction of casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems of long residence time, difficulty in removing inclusions, etc., and achieve the effect of preventing re-oxidation and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

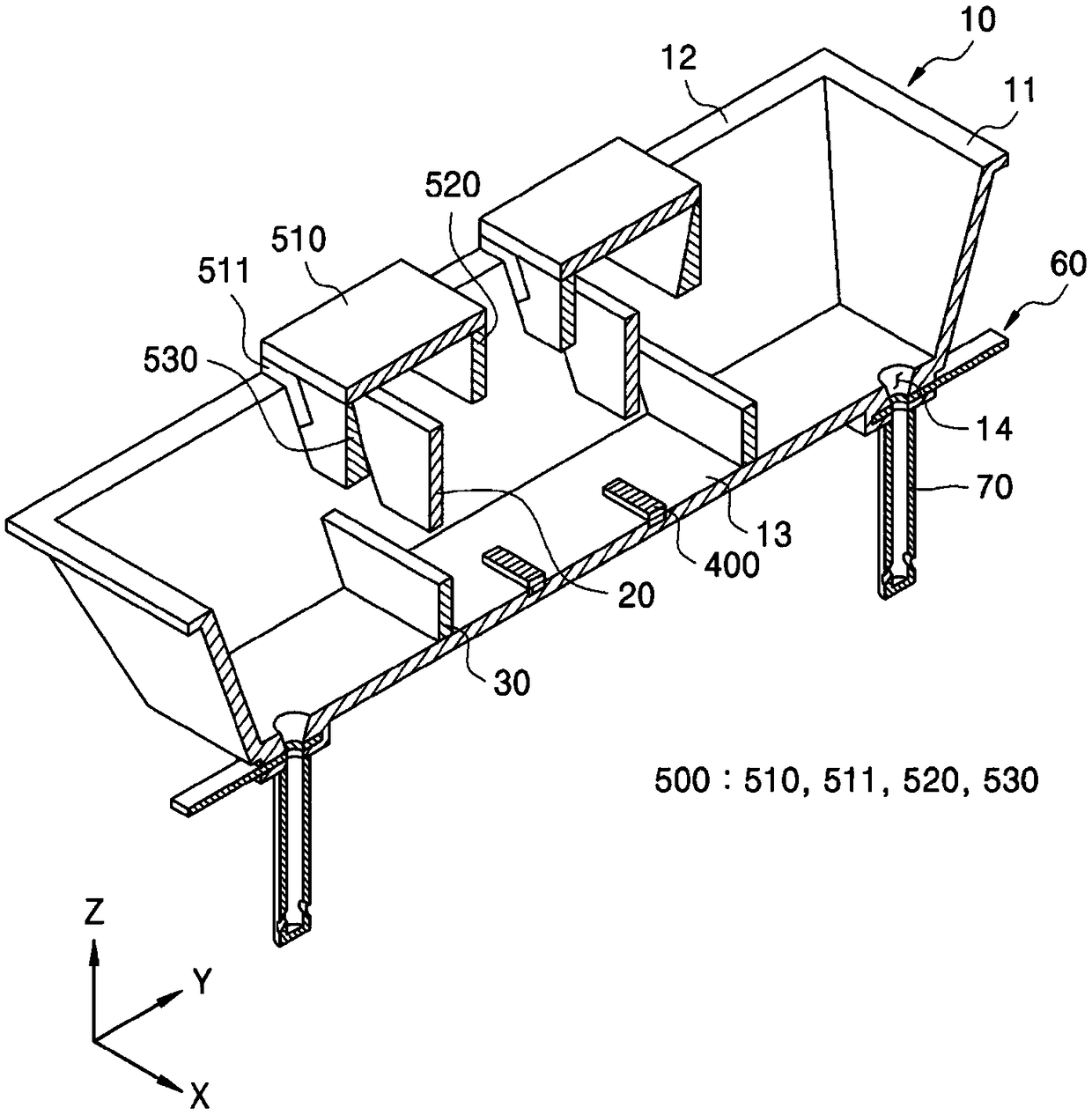

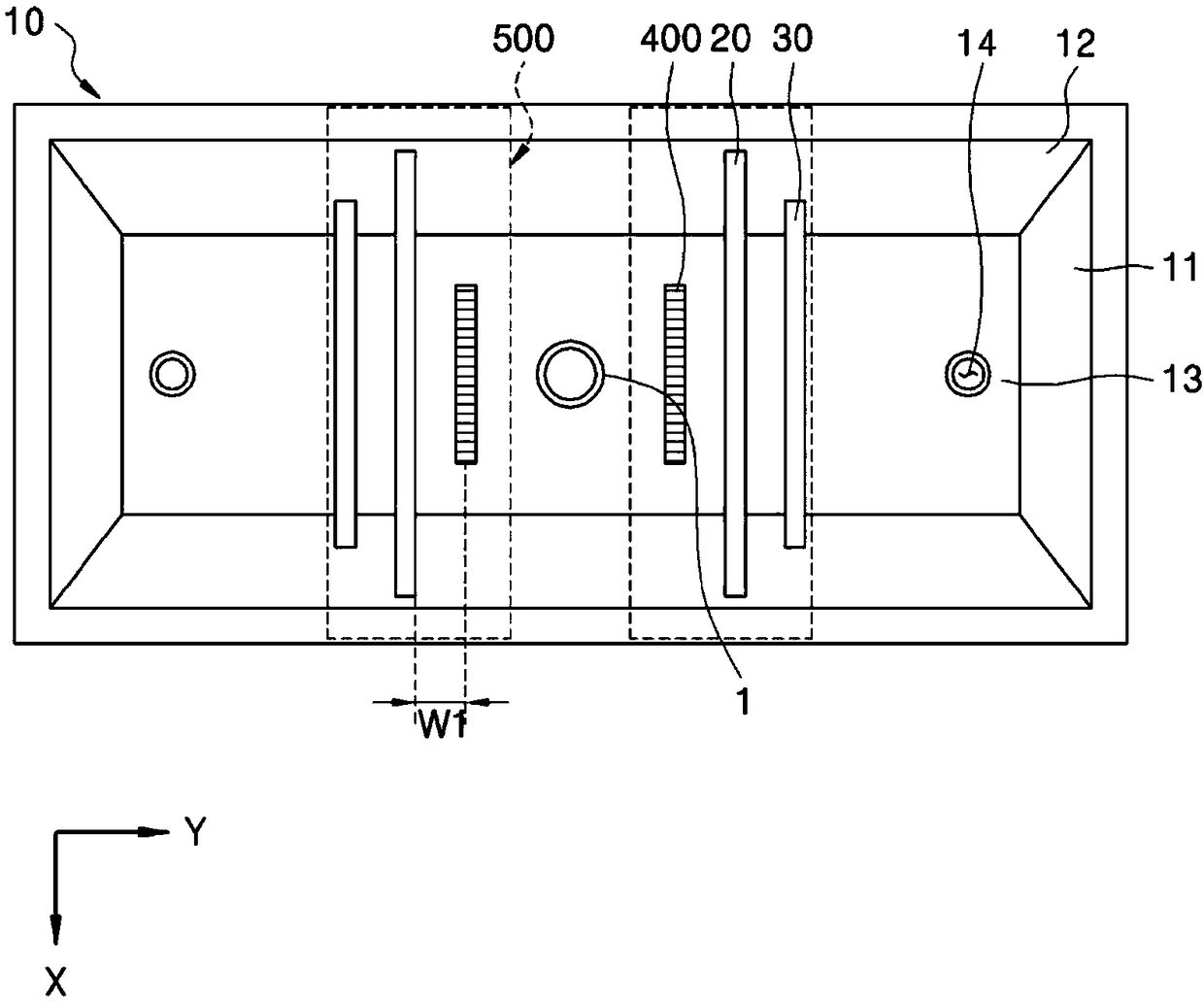

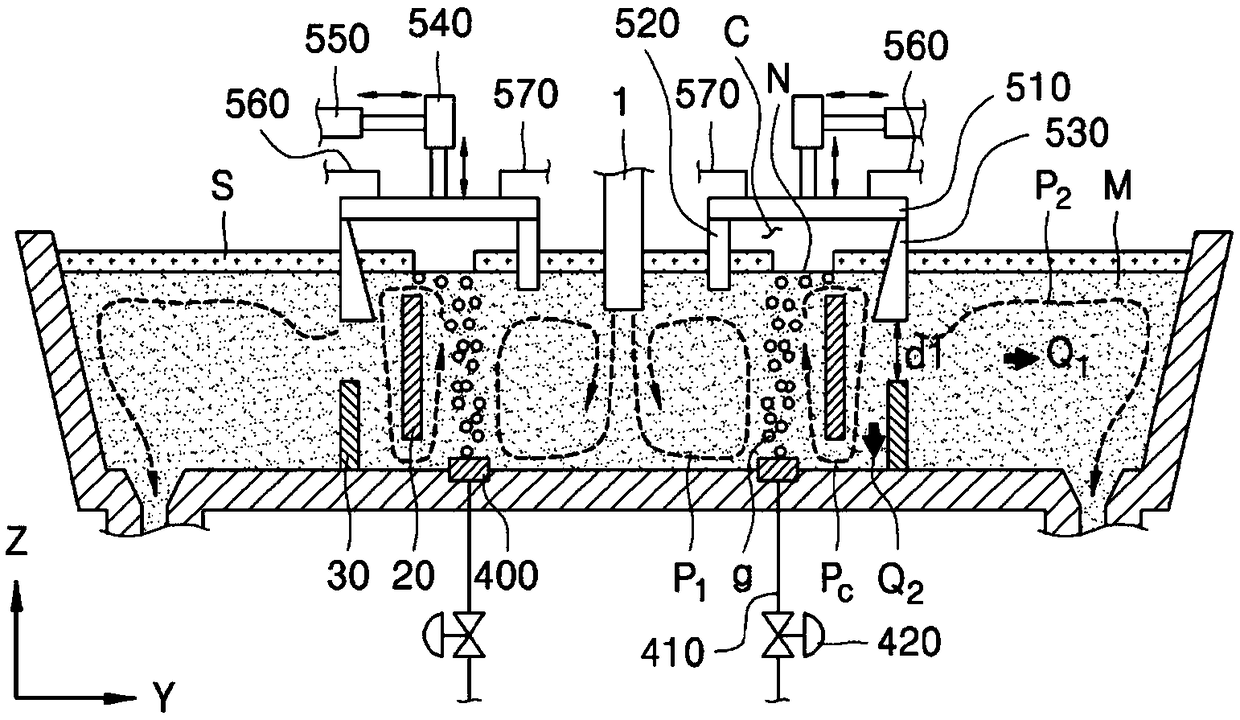

[0067] Hereinafter, embodiments of the present disclosure will be described in detail with reference to the accompanying drawings. However, the present disclosure is not limited to the embodiments disclosed below, but may be implemented in various forms. The embodiments of the present disclosure are provided only to make the disclosure of the present disclosure complete and to fully inform those skilled in the art to which the present disclosure belongs the scope of the present disclosure. Relative proportions and ratios of elements in the drawings may be exaggerated in size to illustrate embodiments of the present disclosure. In addition, the same reference numerals denote the same elements throughout the specification.

[0068] Among the terms used to describe the embodiments of the present disclosure, "upper" and "lower" are used to denote an upper portion and a lower portion, which are a part of a component, respectively. In addition, 'above' and 'below' are used to repr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com