Dual-furnace-chamber garbage treatment device

A technology of garbage disposal equipment and furnace cavity, which is applied in the direction of lighting and heating equipment, incinerators, combustion methods, etc., and can solve problems such as increased workload and cost, low efficiency, and large fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

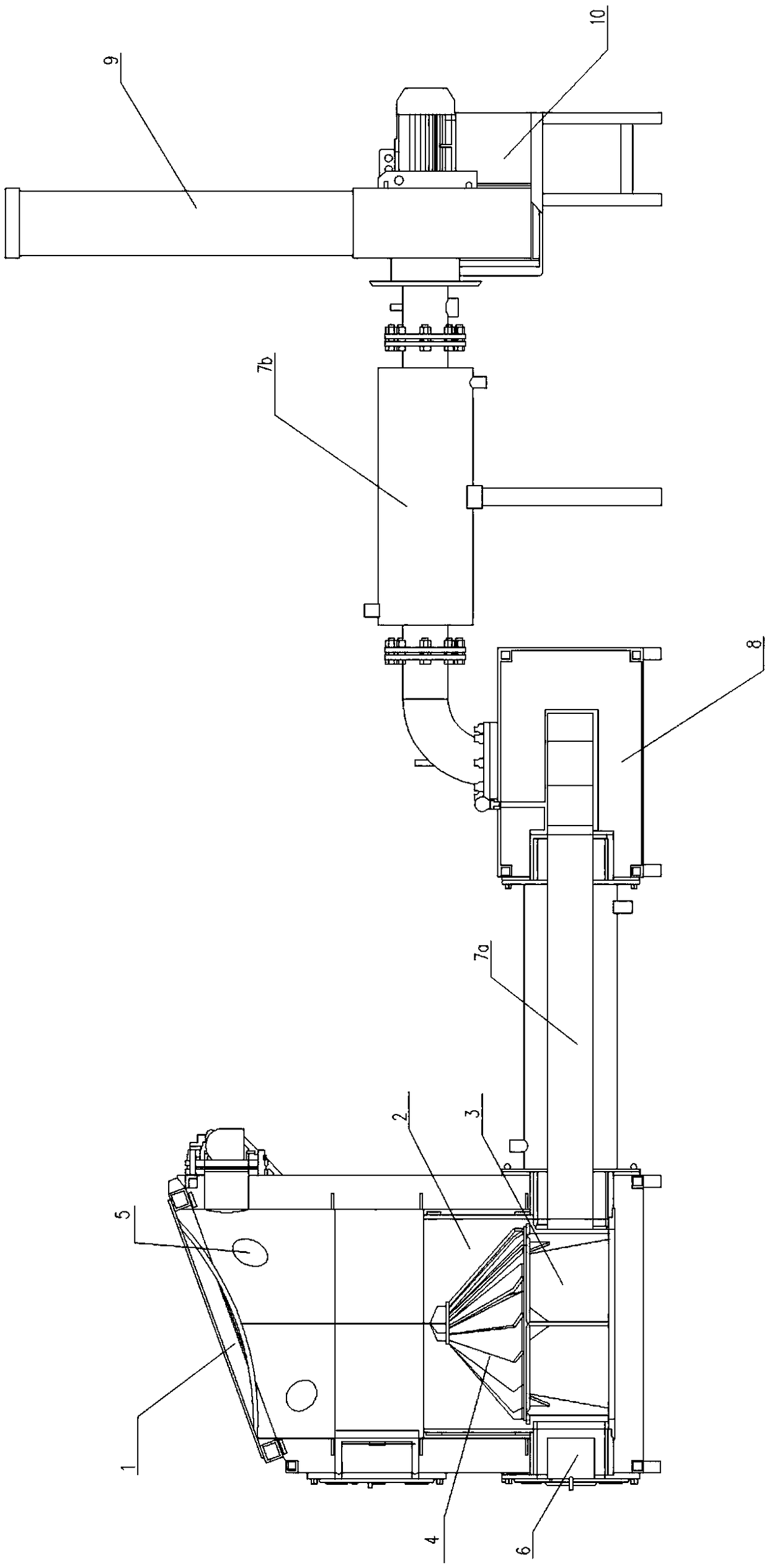

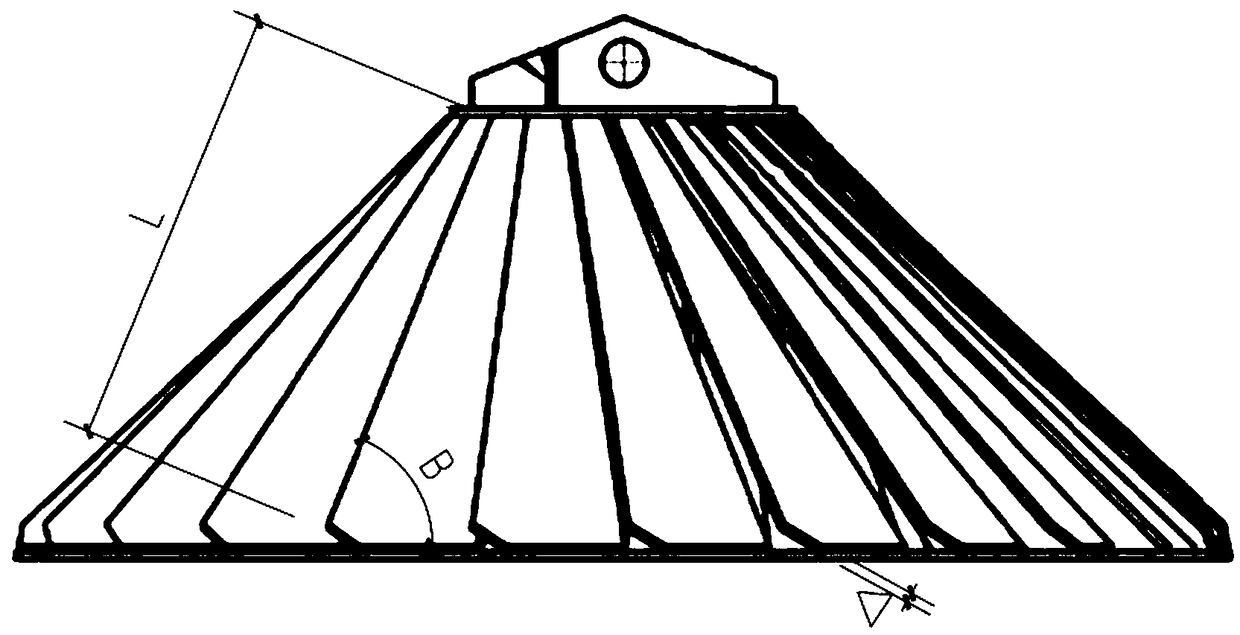

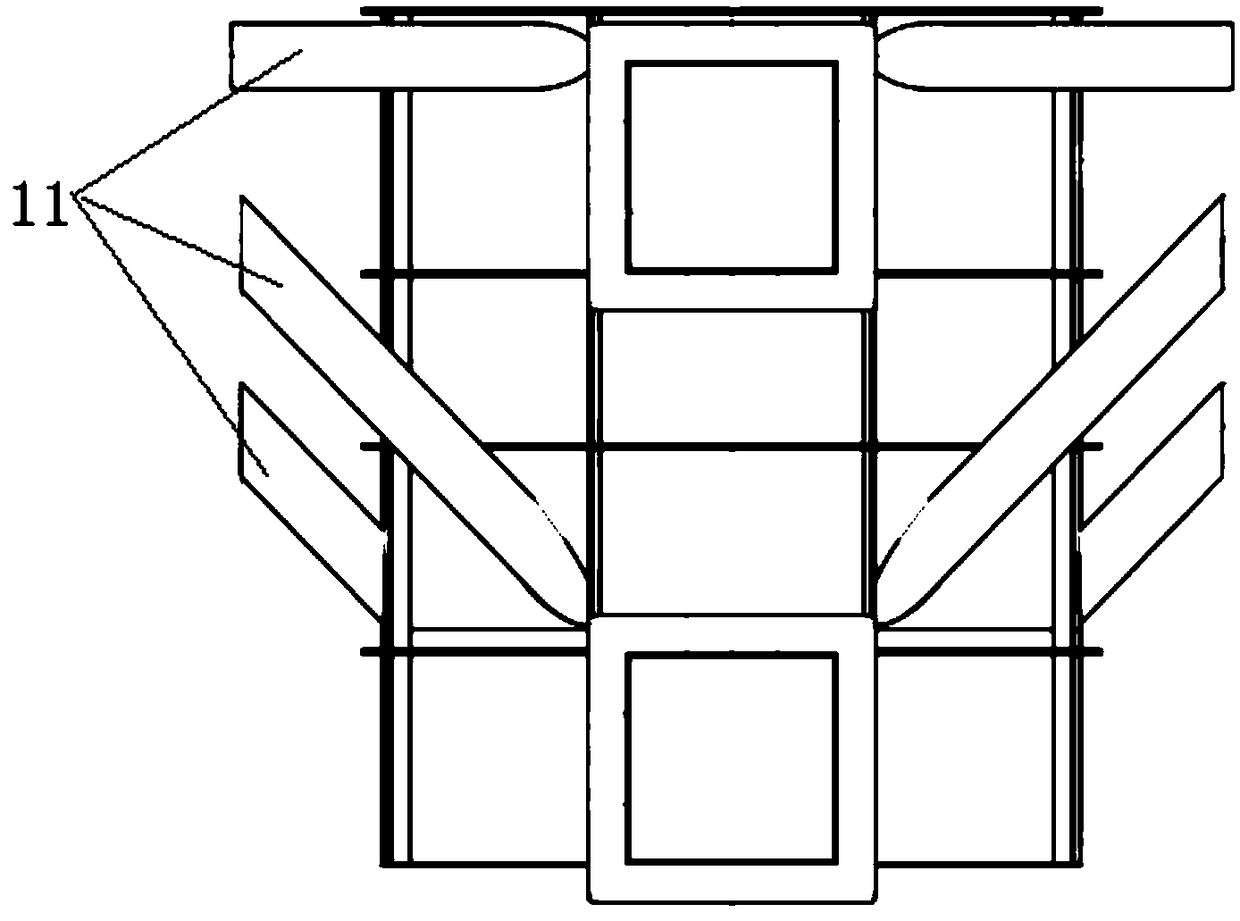

[0019] Such as figure 1 , 4 As shown, a double-cavity garbage disposal equipment includes an upper furnace chamber 2 and a lower furnace chamber 3 arranged up and down, the upper furnace chamber is provided with a feed port 1, and one side of the lower furnace chamber is provided with a slag outlet Port 6, the other side of the lower furnace chamber 3 is provided with gas waste heat recovery pipelines 7a, 7b, the gas waste heat recovery pipeline 7b is connected to the air outlet of the induced draft fan 10, and the air outlet of the induced draft fan 10 is connected to the chimney 9; The above-mentioned furnace cavity 2 is provided with a circular table-shaped plasma reactor 4, and the side wall of the circular table-shaped ion reactor is surrounded by several reaction bars staggered, and the reaction bars are inclined and overlapped successively according to a rotation direction; adjacent reaction bars are overlapped. There is a gap; the gap connects the upper furnace chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com