Method for increasing salt field solarizing and evaporating rate by hydrophilic modified spheres

A technology of hydrophilic modification and evaporation rate, which is applied in the field of solar evaporation in salt fields, can solve problems such as the impact of salt production and quality, slow down the progress of salt production, and reduce evaporation rate, so as to alleviate production reduction, increase production, and reduce land use area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Take the polypropylene hydrophilic modified pellets with a particle size of 3mm, wash them with distilled water, put them in a 60°C oven and dry them for 6 hours before taking them out;

[0016] (2) The pellets are dropped into an evaporation pond equipped with enough 4wt% sodium chloride solution, wherein the area of the evaporation pond is 400cm 2 (20*20cm), make the small ball account for 50% of the area of the evaporation pool through the partition, and let the small ball naturally disperse and float on the surface of the solution after withdrawing the partition;

[0017] (3) Use a fan to simulate natural wind energy, and adjust the wind speed to 1m / s; use a sun lamp to simulate solar energy, adjust the irradiation distance and irradiation intensity, so that the surface irradiation temperature of the solution is 30°C, and simulate the solar evaporation experiment in salt fields;

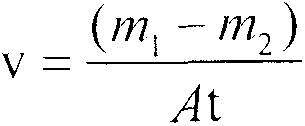

[0018] (4) The evaporation rate was calculated after the experiment continued ...

Embodiment 2

[0021] (1) Take the polypropylene hydrophilic modified pellets with a particle size of 3mm, wash them with distilled water, put them in a 60°C oven and dry them for 6 hours before taking them out;

[0022] (2) The pellet is dropped into an evaporation pond equipped with enough 10wt% sodium chloride solution, wherein the area of the evaporation pond is 400cm 2 (20*20cm), make the small ball account for 30% of the area of the evaporation pool through the partition, and let the small ball naturally disperse and float on the surface of the solution after withdrawing the partition;

[0023] (3) Use a fan to simulate natural wind energy, and adjust the wind speed to 4m / s; use a sun lamp to simulate solar energy, adjust the irradiation distance and irradiation intensity, so that the surface irradiation temperature of the solution is 30°C, and simulate the solar evaporation experiment in salt fields;

[0024] (4) The evaporation rate was calculated after the experiment continued f...

Embodiment 3

[0027] (1) Take the polyethersulfone hydrophilic modified pellets with a particle size of 4mm, wash them with distilled water, put them in an oven at 60°C and dry them for 6 hours before taking them out;

[0028] (2) The pellets are dropped into an evaporation pond equipped with enough 3.5wt% sodium chloride solution, wherein the area of the evaporation pond is 400cm 2 (20*20cm), make the small ball account for 50% of the area of the evaporation pool through the partition, and let the small ball naturally disperse and float on the surface of the solution after withdrawing the partition;

[0029] (3) Use a fan to simulate natural wind energy, and adjust the wind speed to 10m / s; use a sun lamp to simulate solar energy, adjust the irradiation distance and irradiation intensity, so that the solution surface irradiation temperature is 50°C, and simulate the salt field solar evaporation experiment;

[0030] (4) The evaporation rate was calculated after the experiment continued f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com