A kind of negative electrode material of lithium ion battery and preparation method thereof

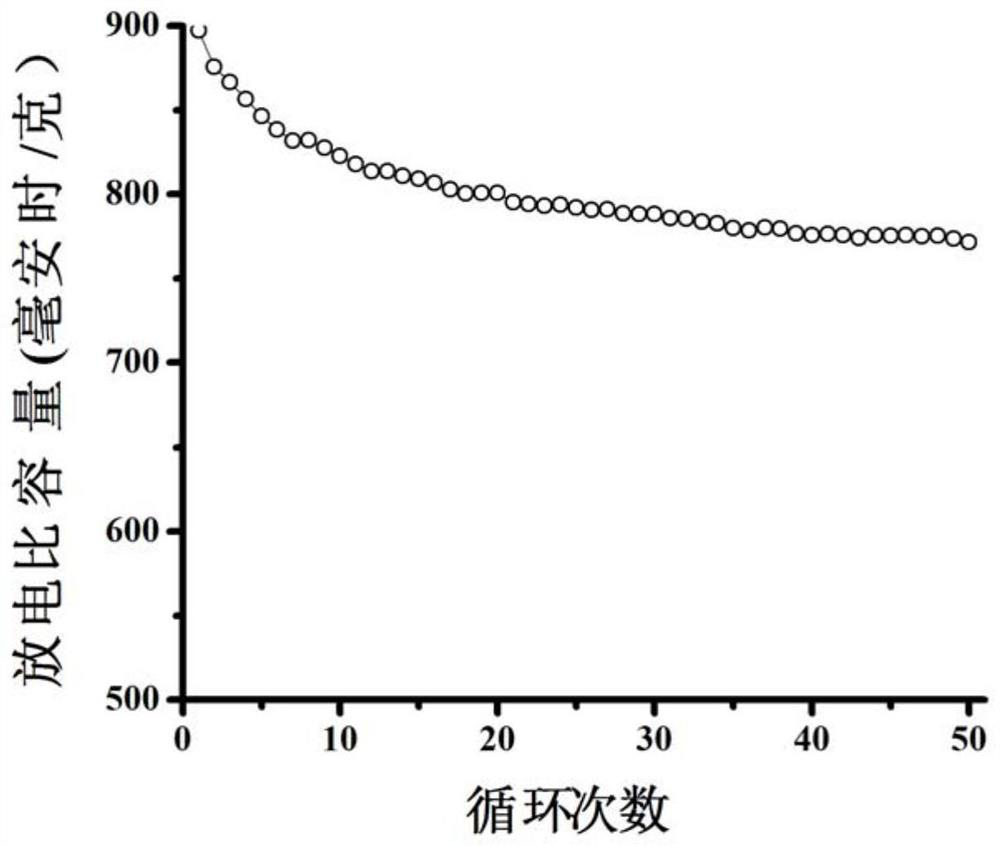

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low ion transfer rate, poor conductivity, material breakage and falling off, etc., to improve cycle stability, reduce vacancy formation energy, Effect of large internal cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

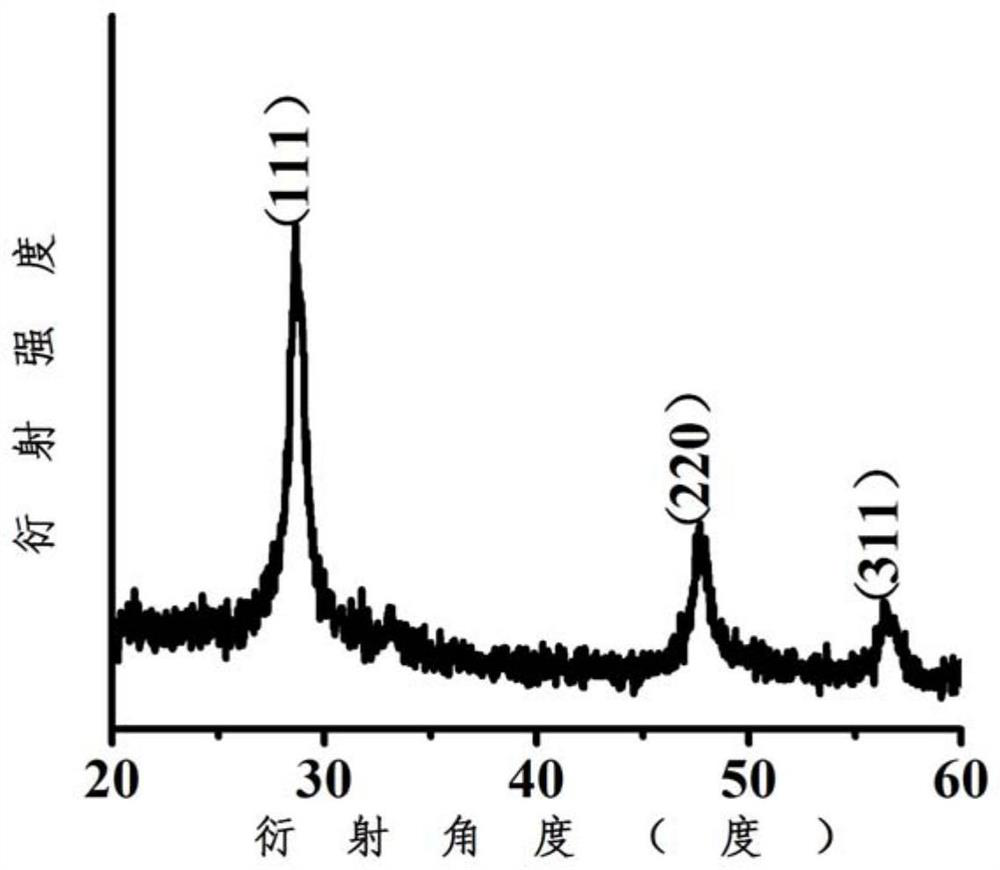

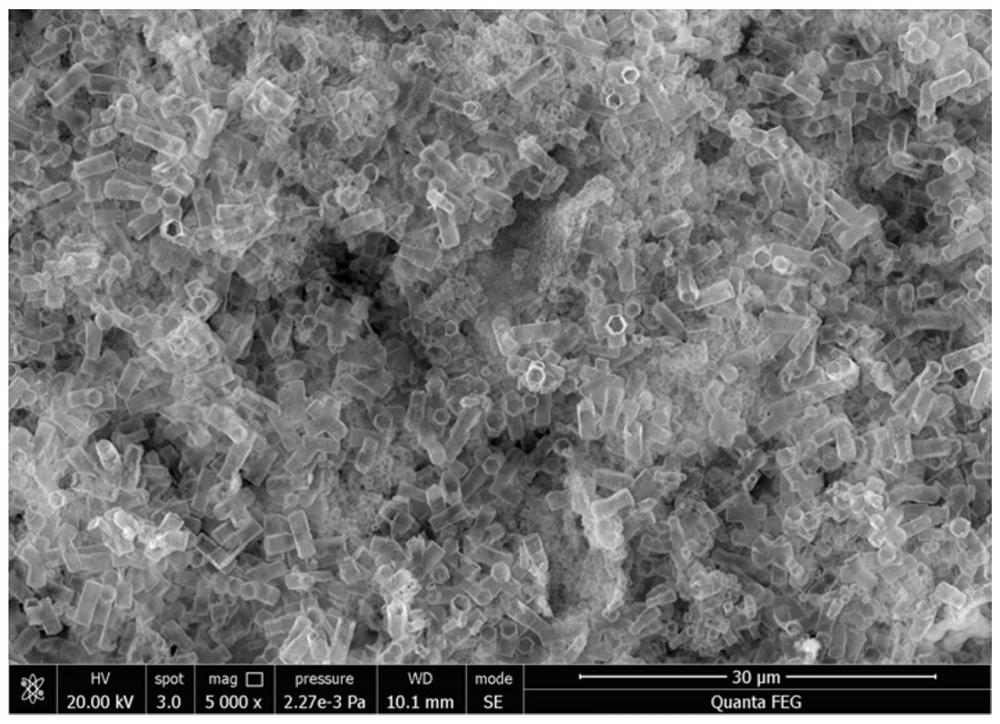

[0034] In the negative electrode material of the lithium ion battery, the negative electrode active material is nitrogen-doped zinc sulfide nanotube. The nitrogen doped

[0035] The heterozinc sulfide nanotubes utilize ammonia gas as a nitrogen source.

[0036] The preparation method of described lithium-ion battery negative electrode material, comprises the following steps:

[0037] (1) Preparation of zinc sulfide nanotubes:

[0038] Take 150mL of deionized water, add 1.5g of zinc chloride and 1.5g of hexamethylenetetramine and stir evenly, heat in a water bath at 80°C for 8 hours, then add 8g of sodium sulfide and 0.8mL of thioglycolic acid, stir evenly, and again Heat in a water bath at 80°C for 8 hours, collect the product by centrifugation, soak in acetic acid solution with a mass fraction of 10% to 30% for 20 minutes, after the reaction is completed, collect the product by centrifugation, wash with deionized water three times, and dry at 60°C for 12 hours ZnS nanotube...

Embodiment 2

[0045] The preparation method of described lithium-ion battery negative electrode material, comprises the following steps:

[0046] (1) Preparation of ZnS nanotubes:

[0047] Take 100mL of deionized water, add 1g of zinc chloride and 1g of hexamethylenetetramine and stir evenly, heat in a water bath at 60°C for 6 hours, then add 5g of sodium sulfide and 0.5mL of thioglycolic acid, stir evenly, and heat again at 60°C Heat in a water bath for 6 hours, collect the product by centrifugation, soak in acetic acid solution with a mass fraction of 10% to 30% for 10 minutes, after the reaction is completed, collect the product by centrifugation, wash with deionized water three times, and dry at 60°C for 12 hours. Zinc sulfide nanotubes were obtained.

[0048] (2) Preparation of high-vacancy nitrogen-doped ZnS nanotubes:

[0049] Take 1 g of zinc sulfide nanotubes prepared in step (1), place them in a tube furnace, and feed nitrogen and ammonia at the same time, wherein the nitrogen g...

Embodiment 3

[0051] The preparation method of described lithium-ion battery negative electrode material, comprises the following steps:

[0052] (1) Preparation of ZnS nanotubes:

[0053] Take 200mL of deionized water, add 2g of zinc chloride and 2g of hexamethylenetetramine and stir evenly, add 10g of sodium sulfide and 1mL of thioglycolic acid in a water bath at 90°C for 12 hours, then add 10g of sodium sulfide and 1mL of thioglycolic acid, stir evenly, and again in a 90°C water bath Heating for 12 hours, collecting the product by centrifugation, soaking in acetic acid solution with a mass fraction of 10% to 30% for 30 minutes, after the reaction is completed, collecting the product by centrifugation, washing with deionized water three times, and drying at 60°C for 12 hours to obtain ZnS nanotubes.

[0054] (2) Preparation of high-vacancy nitrogen-doped ZnS nanotubes:

[0055] Take 2 g of zinc sulfide nanotubes prepared in step (1), place them in a tube furnace, and feed nitrogen and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com